Explosion-proof double-value capacitor

A technology of capacitors and capacitors, which is applied in the direction of capacitors and electrical components, and can solve the problems of poor heat dissipation, low reliability, and short life of the first capacitor core package 3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

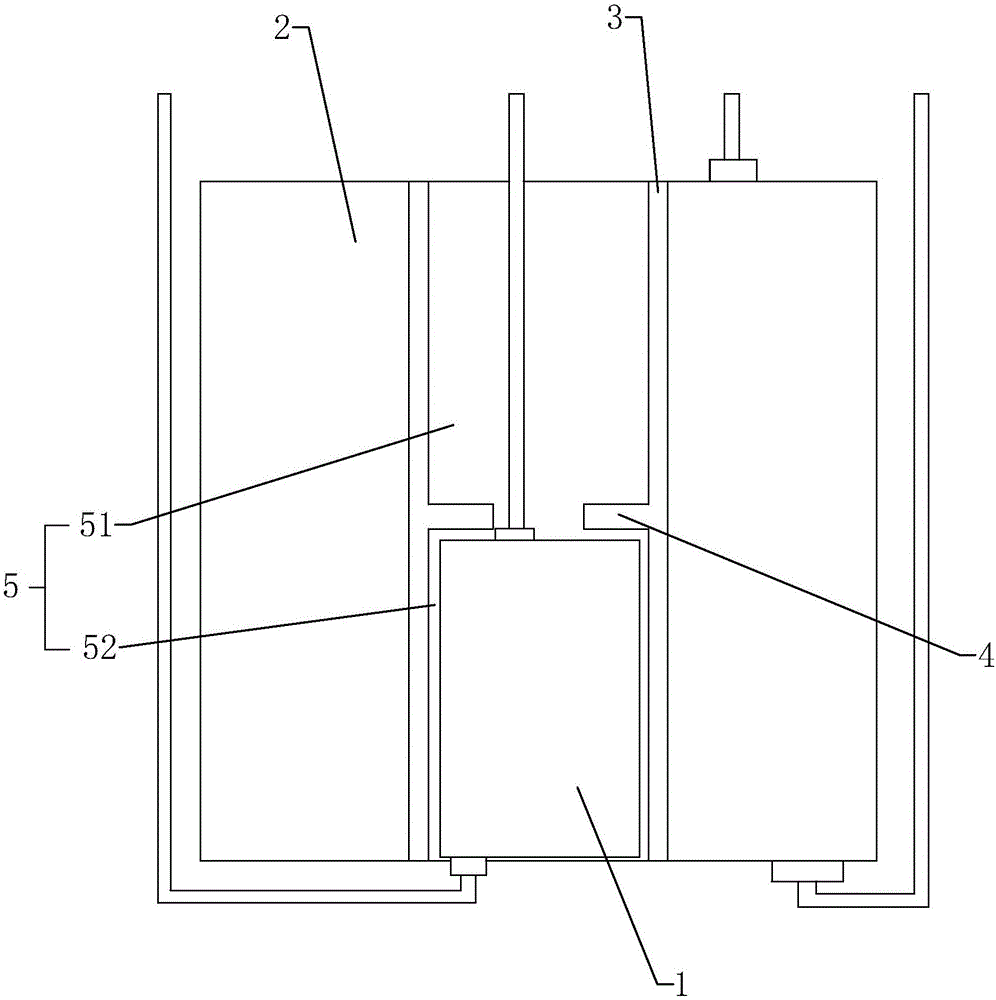

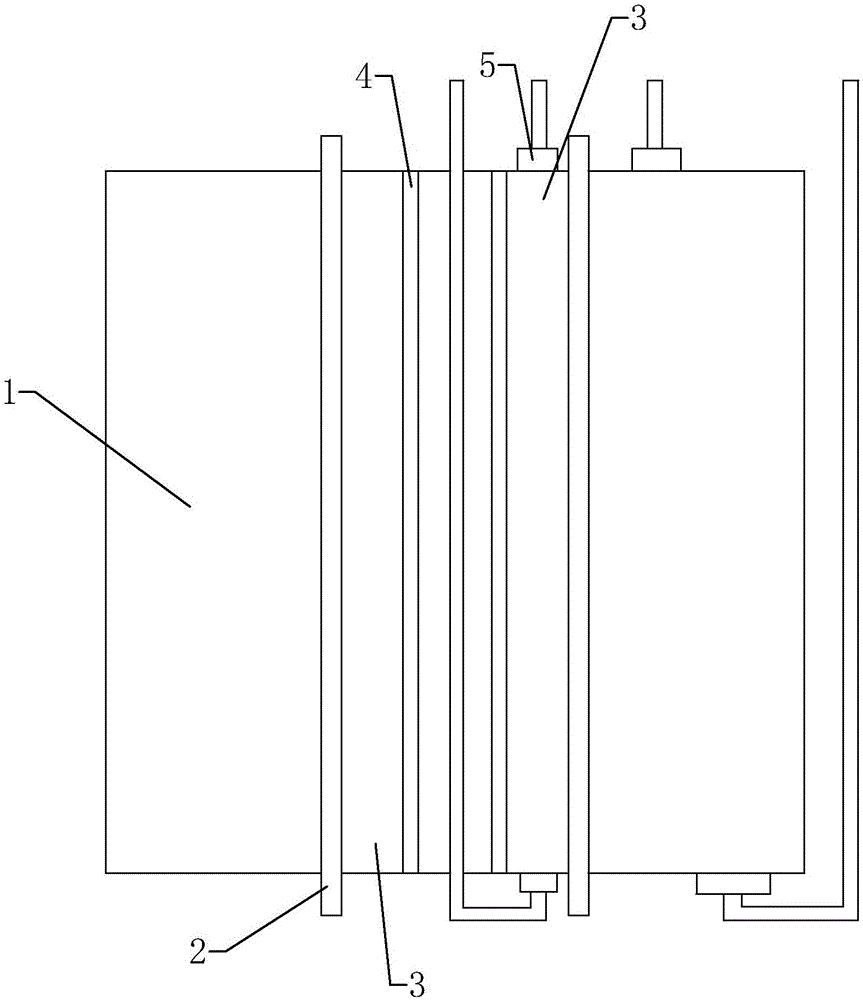

[0015] pass figure 1 The explosion-proof double value capacitor of the present invention is further described.

[0016] An explosion-proof double-value capacitor, comprising a first capacitor core package 1, a mandrel 3 and a second capacitor core package 2, the first capacitor core package 1 is a polypropylene film capacitor, which is wound from a polypropylene film, and has a Cylindrical, the second capacitor core pack 2 is an aluminum electrolytic capacitor, which is made of aluminum foil and is cylindrical. It is characterized in that: the height of the first capacitor core package 1 is smaller than the height of the second capacitor core package 2, the height mentioned here is the axial length of the columnar first capacitor core package 1 and the second capacitor core package 2, here It should be noted that the height of the first capacitor core package 1 is smaller than the height of the second capacitor core package 2, that is, the height of the first capacitor core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com