Heat dissipation mechanism for new energy automobile battery management

A new energy vehicle and battery management technology, which is applied in the field of heat dissipation mechanism for battery management of new energy vehicles, can solve the problems of reducing the service life of the battery pack, high power and density of the battery pack, and insufficient heat dissipation and adsorption cooling. problems, to achieve the effect of improving the cooling space and effectiveness, increasing the service life, and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

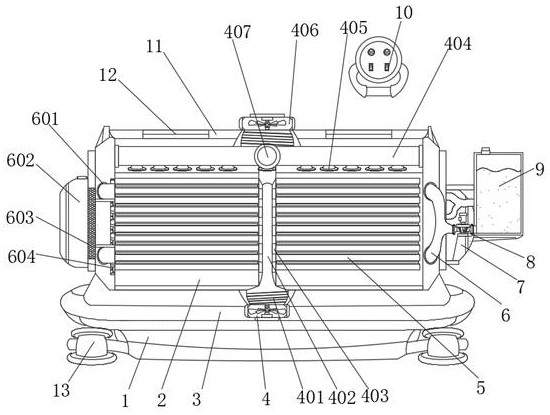

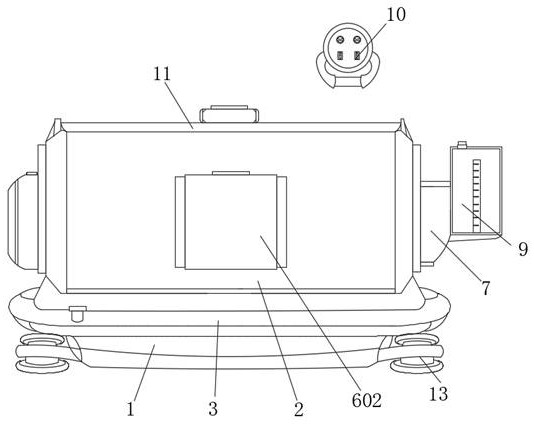

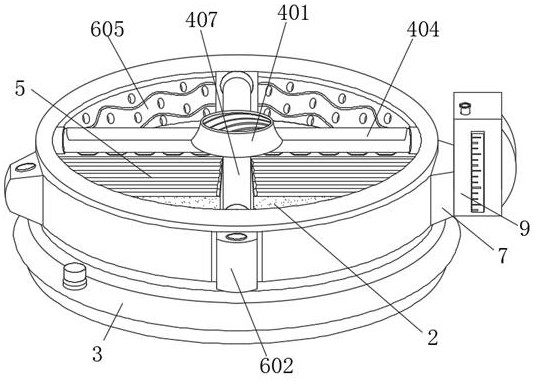

[0032] Example 1, such as Figure 1-3 As shown, when the heat dissipation fan A4 and the heat dissipation fan B406 are started, the inner spiral air duct 401 and the air guide column 402 are used to cooperate with each other, so that the heat dissipation fan A4 forms a wind force and circulates in a spiral flow guide structure, and flows between the air guide column 402 and the air guide column 402. Blind hole A403 cooperates to discharge, through the connection of air guide pipe A404 and air guide pipe B407 and the placement of blind hole B405, the wind force emitted by cooling fan B406 flows out from blind hole B405, and the annular groove 2 can be diffused from inside to outside Guided airflow not only cooperates with cooling fins 5 to air-cool and dissipate the battery pack, but also transfers the dissipated heat to the inner wall of the annular groove 2, and cooperates with the water-cooling structure to effectively dissipate heat and enhance the practical application effe...

Embodiment 2

[0033] Example 2, such as figure 1 and Figure 6As shown, the installation cooperation of the rubber column 13 and the positioning of the mounting seat 1 have played an auxiliary fixing role. At the same time, under the installation cooperation of the rubber column 13 and the protective airbag 3, the vibration and impact of the device are alleviated, and the installation of the device is improved. Stability and shock resistance reduce damage to components.

[0034] Working principle: when the device is in use, the battery pack is divided into four groups under the separation of the cooling fins 5 and placed in the annular groove 2, and the cooling fan A4, the water pump 8 and the cooling fan B406 are respectively activated by the controller 10, and the heat dissipation When the fan A4 and the cooling fan B406 start, the cooling air is blown into the annular groove 2 and guided, so that the heat is extended to the inner wall of the annular groove 2 under the heat dissipation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com