High voltage resistant connection socket, plug, connector and working method for power system

A power system and high-voltage-resistant technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of cumbersome processing, installation and use, high requirements for operators, and unreliable connection, etc., and achieve excellent comprehensiveness Excellent performance, high mechanical strength, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

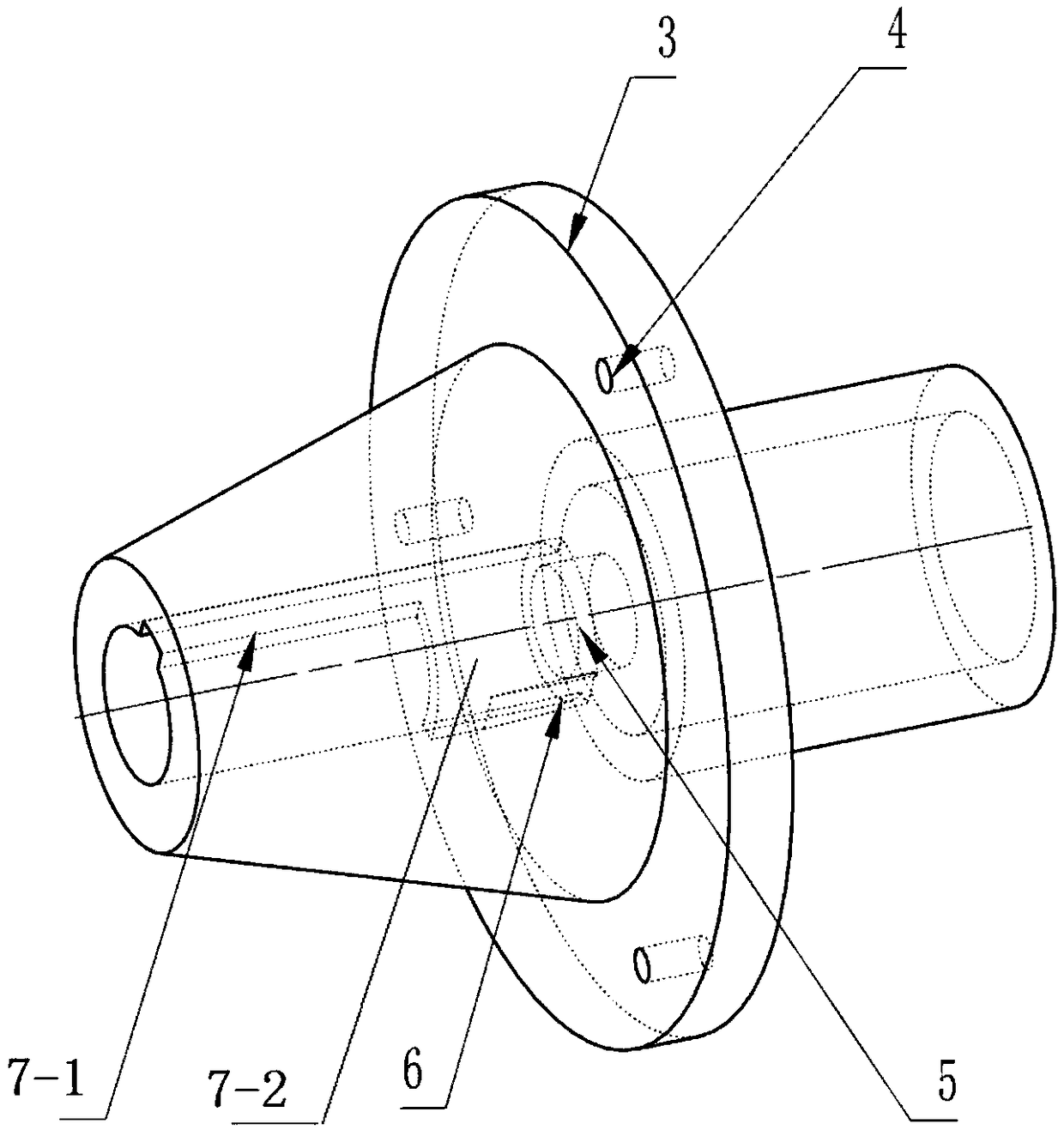

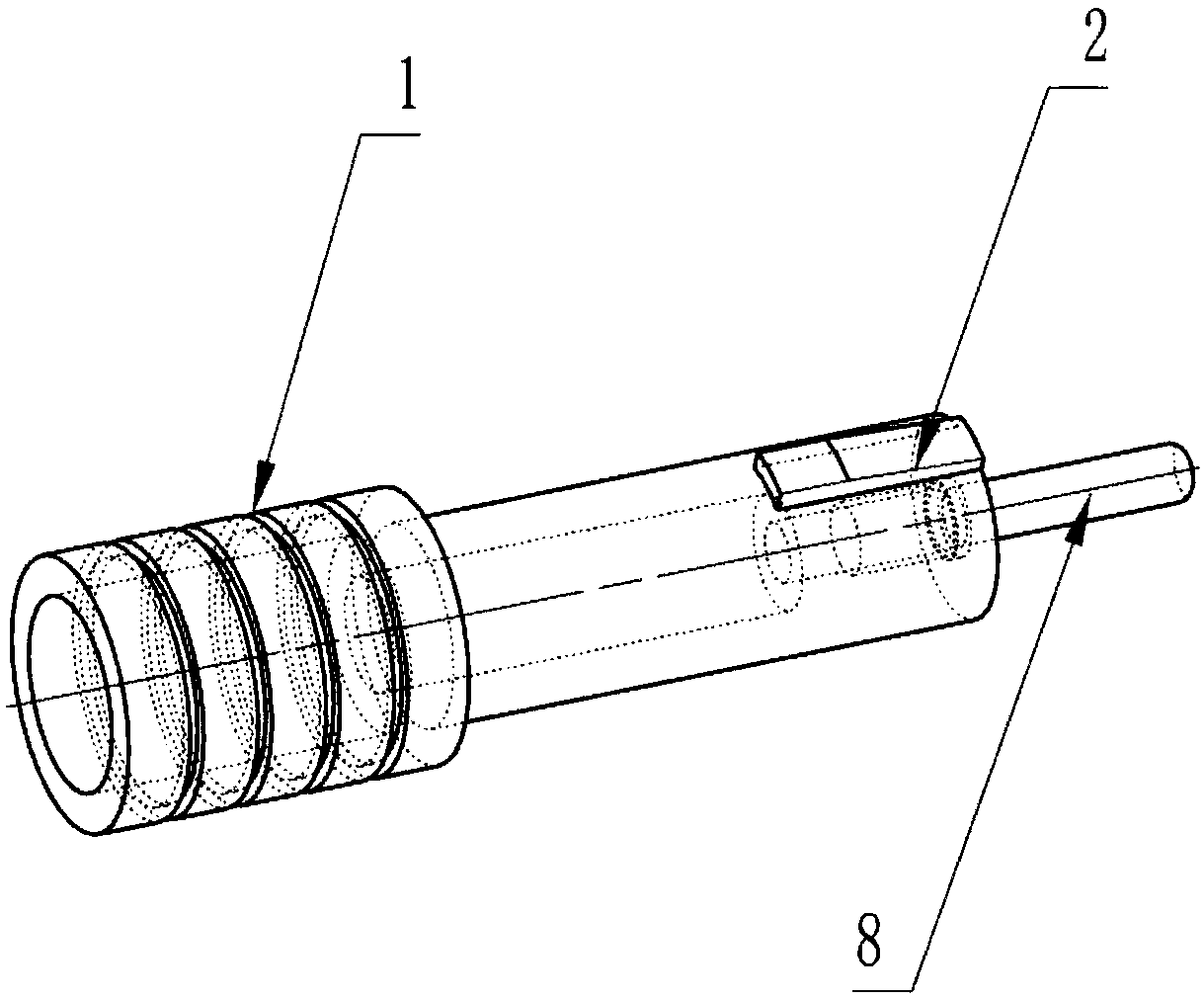

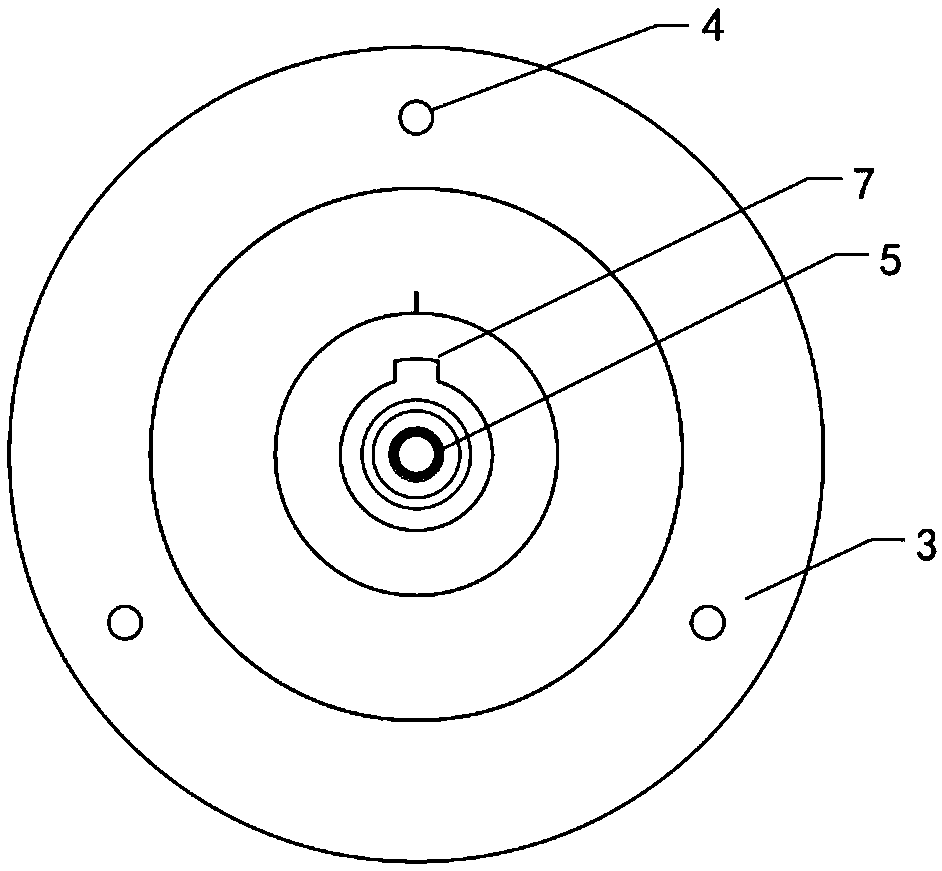

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0037] Both the plug and the socket of the present invention are processed by turning and milling polytetrafluoroethylene. This material is resistant to acid and alkali, and various organic solvents. At the same time, it has the characteristics of high mechanical strength, high and low temperature resistance (-190 ° C ~ 260 ° C), high insulation and low friction coefficient, and has outstanding excellent comprehensive performance. The connector of the present invention can withstand a high voltage of up to 10kV, and can be applied to instruments and equipment such as DC high-voltage precision power supplies. The main parts are all made of polytetrafluoroethylene (Teflon) turning and milling, which has the characteristics of high mechanical strength, high and low temperature resistance, high insulation, small contact resistance and acid and alkali resistance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com