Rubber strip clamping type automobile sunroof guide rail

A rubber strip clamping and car sunroof technology, which is applied to the installation of vehicle parts, door/window accessories, window glass, etc., can solve the problems of increasing production costs, increasing labor costs, and affecting user experience, so as to eliminate costs , reduce labor costs, and reduce the effect of the process of sticking double-sided tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

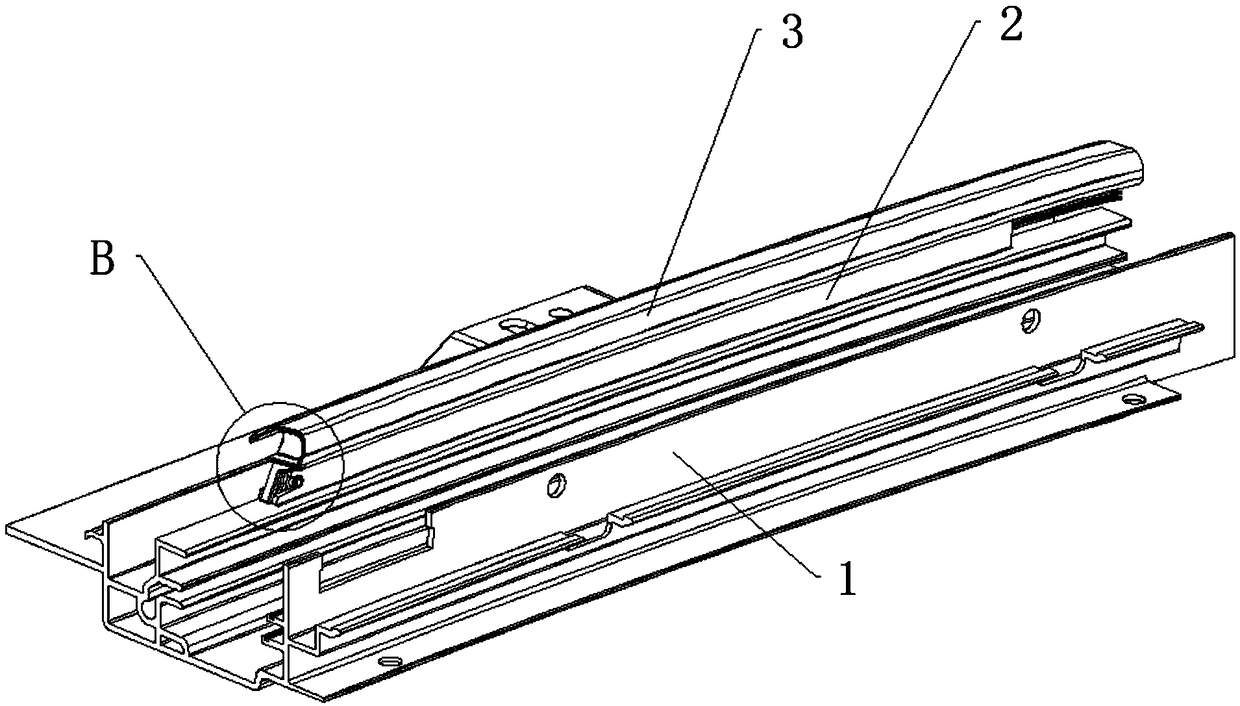

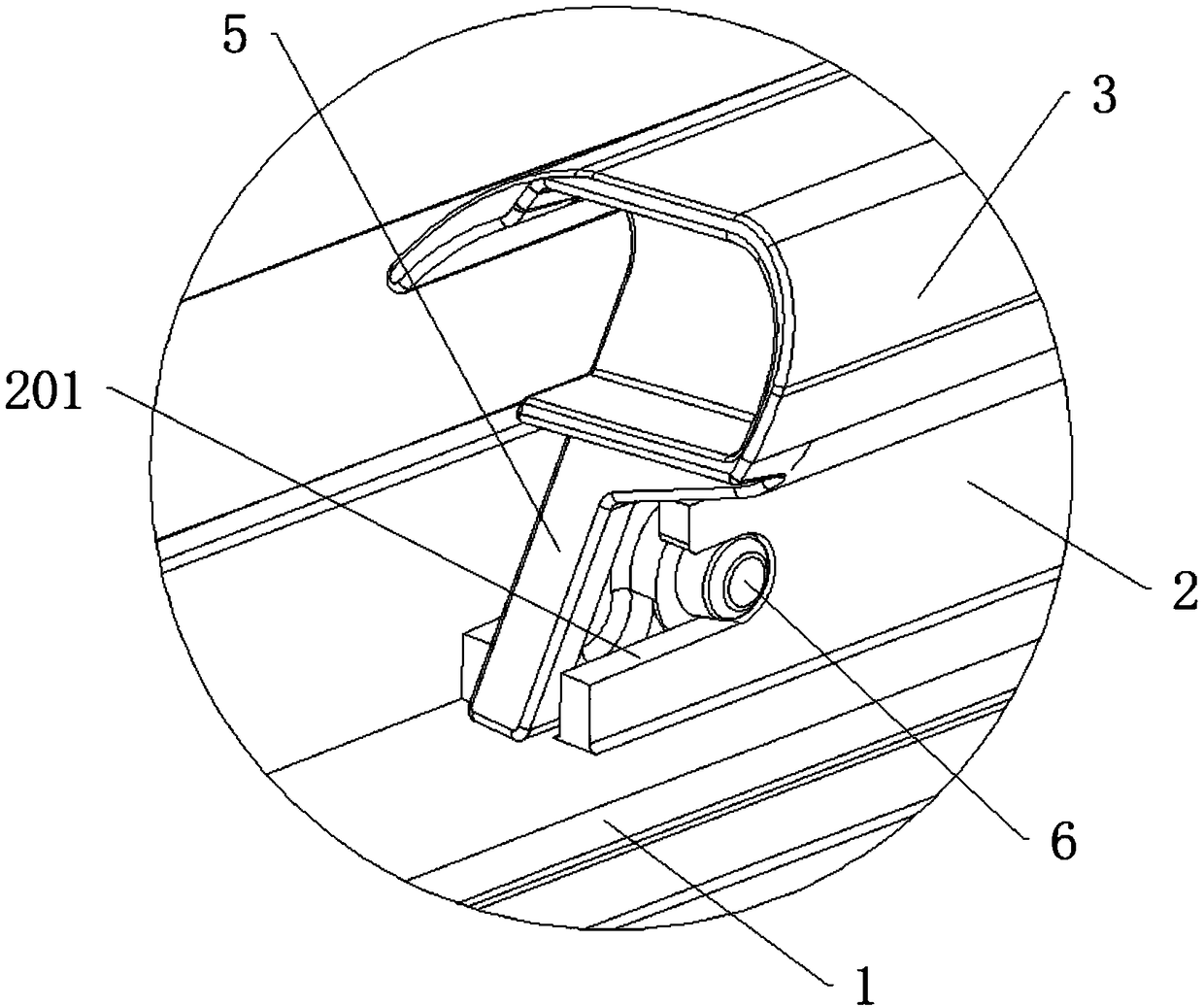

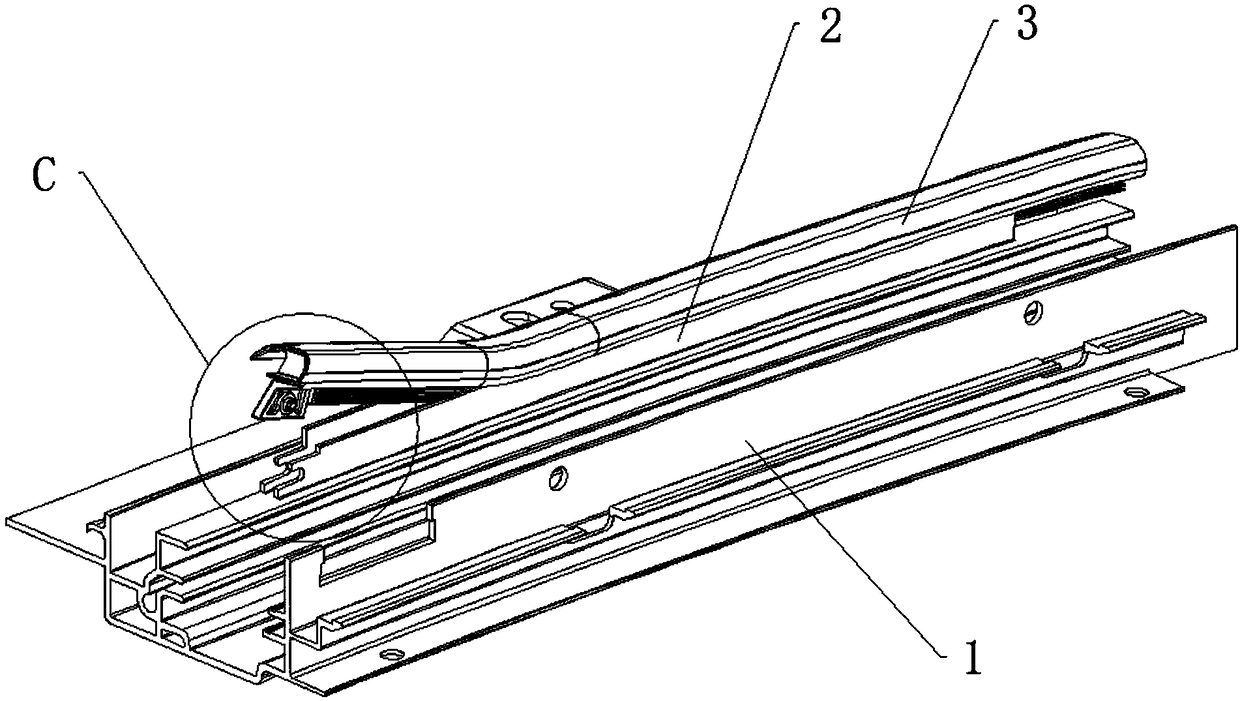

[0044] see Figure 1-4, a rubber strip clamping type car sunroof guide rail, including a second bracket 1, a pair of second snap-in pieces 2 are fixedly connected to the upper end of the second bracket 1, and a second rubber is arranged between the pair of second snap-in slots 2 The strip main body 3 and the pair of second clamping pieces 2 can be used as installation grooves for the second rubber strip main body 3, and a pair of side walls of the second rubber strip main body 3 are fixedly connected with a plurality of uniformly distributed reinforcing fins 301, Moreover, the reinforcing fins 301 are all located between a pair of second locking pieces 2, and the reinforcing fins 301 and the second locking pieces 2 are interference fit, which can greatly enhance the stability of the second rubber strip main body 3. One end of the main body 3 of the two rubber strips is fixedly connected with a second connector 5, and a pair of clamping columns 6 are fixedly connected on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com