Solution storage device

A liquid storage device and solution technology, which is applied in the processing of electrical components, insulating substrates/layers, printed circuit manufacturing, etc. The effect of overflowing the cylinder and avoiding the static caking of the film slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

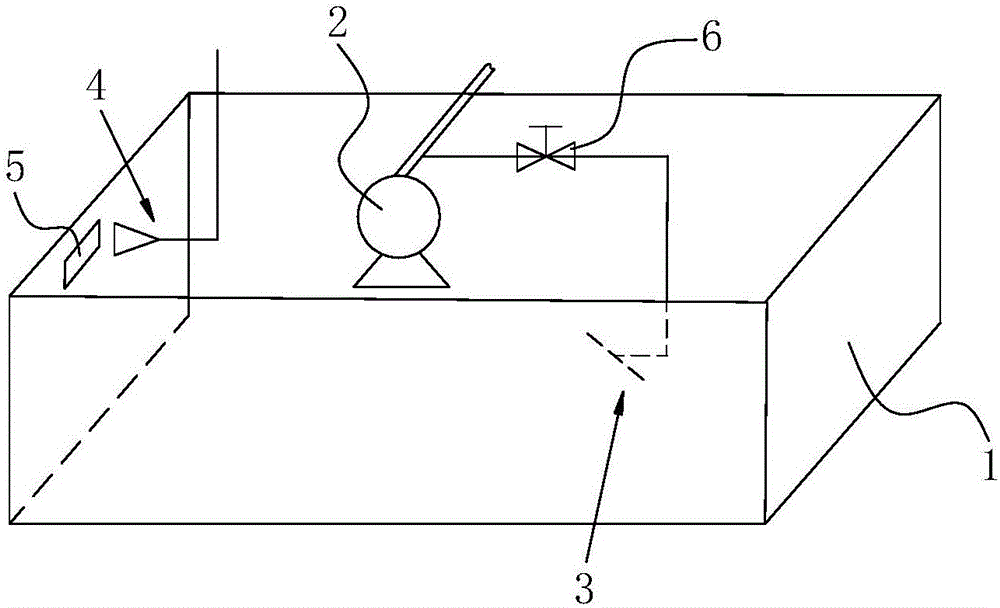

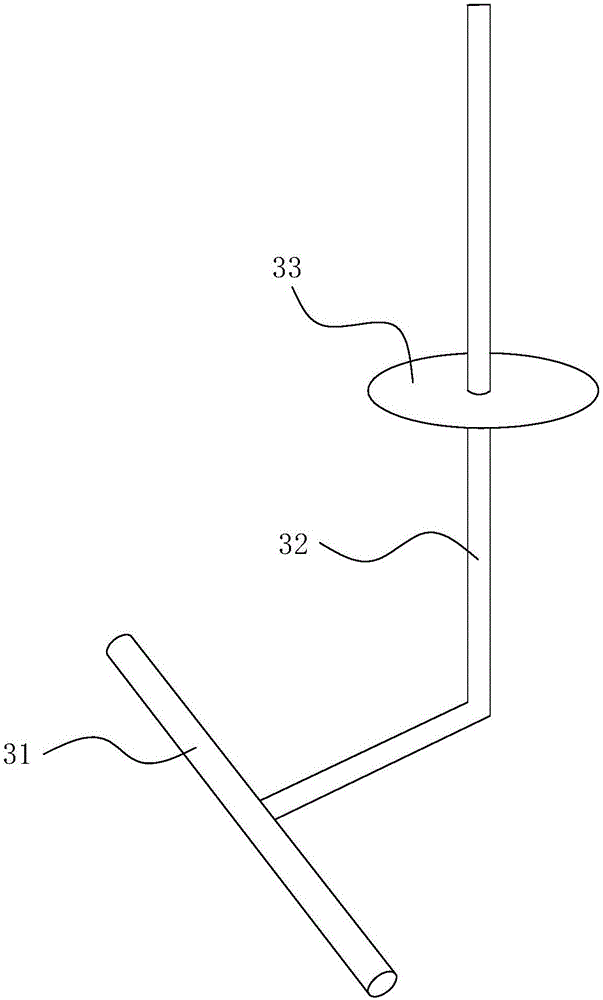

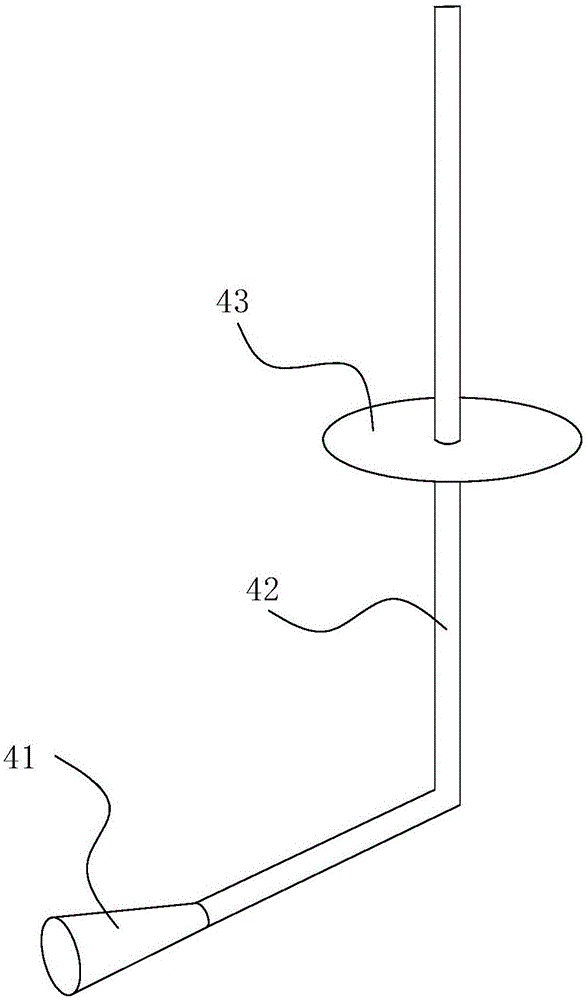

[0047] Figure 1 to Figure 3 As shown, a liquid storage device includes a cylinder 1 for storing the solution, a power pump 2 for driving the output of the solution, and a first disturbance nozzle 3 for driving the flow of the solution, and the side wall of the cylinder 1 is opened There is an overflow port 5, the power pump 2 is installed inside the cylinder body 1, the first disturbance nozzle 3 is installed inside the cylinder body 1, the first disturbance nozzle 3 and the power pump 2 connections. The overflow port 5 is arranged on the side wall of the cylinder body 1 near the top. The power pump 2 is connected to an external spray head for spraying the surface of the copper clad laminate. By arranging the first disturbance nozzle 3, the solution is disturbed to keep the solution in a state of motion, thereby avoiding static agglomeration of film residue in the solution and blocking the overflow port 5. This solution is based on the centrifugal membrane slag filtration,...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is:

[0054] The first fixed base is installed on the cylinder body through a first lifting mechanism, and the first fixed base can drive the first nozzle branch pipe and the hole discharge pipe to move up and down. A liquid level sensor is provided on the side wall of the cylinder, and the liquid level sensor is electrically connected to the first lifting mechanism, so that the height of the hole discharge pipe can be automatically adjusted according to the liquid level of the solution in the cylinder , so as to ensure that the drain pipe is located at the liquid level of the solution.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is:

[0057] The hole-discharging pipe is obliquely fixed on the branch pipe of the first spray head relative to the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com