Automatic meat ball forming machine

A meatball machine, automatic technology, applied in meat processing, slaughtering, food science and other directions, can solve the problems affecting the quality and taste of meatballs, the consistency of meatballs cannot be guaranteed, and pollution, etc., to achieve good consistency and speed. Fast, great-tasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

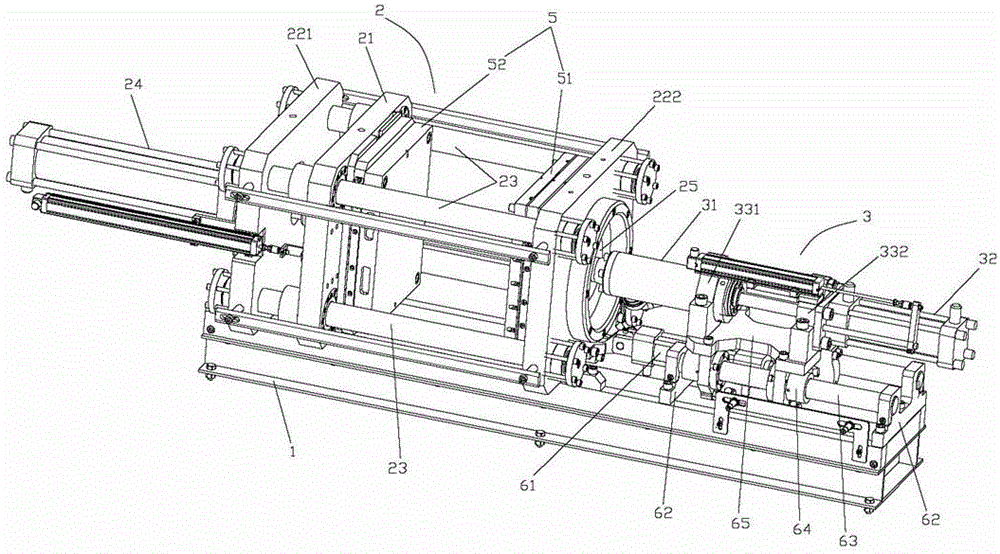

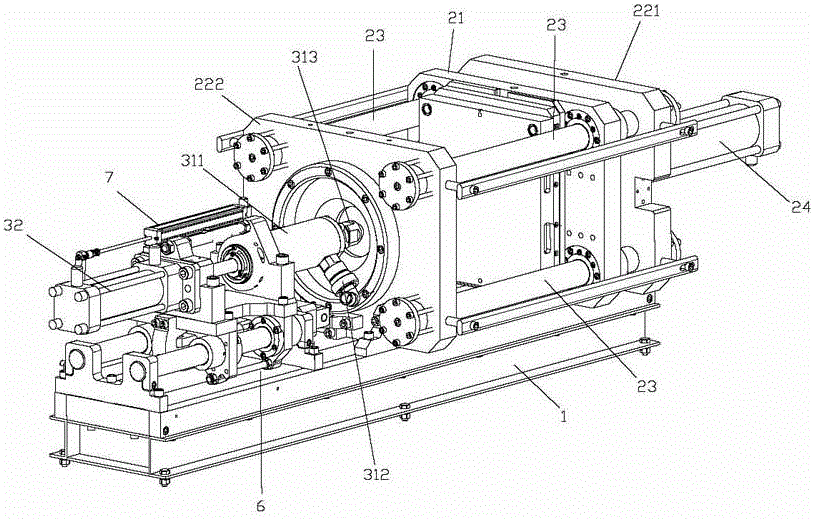

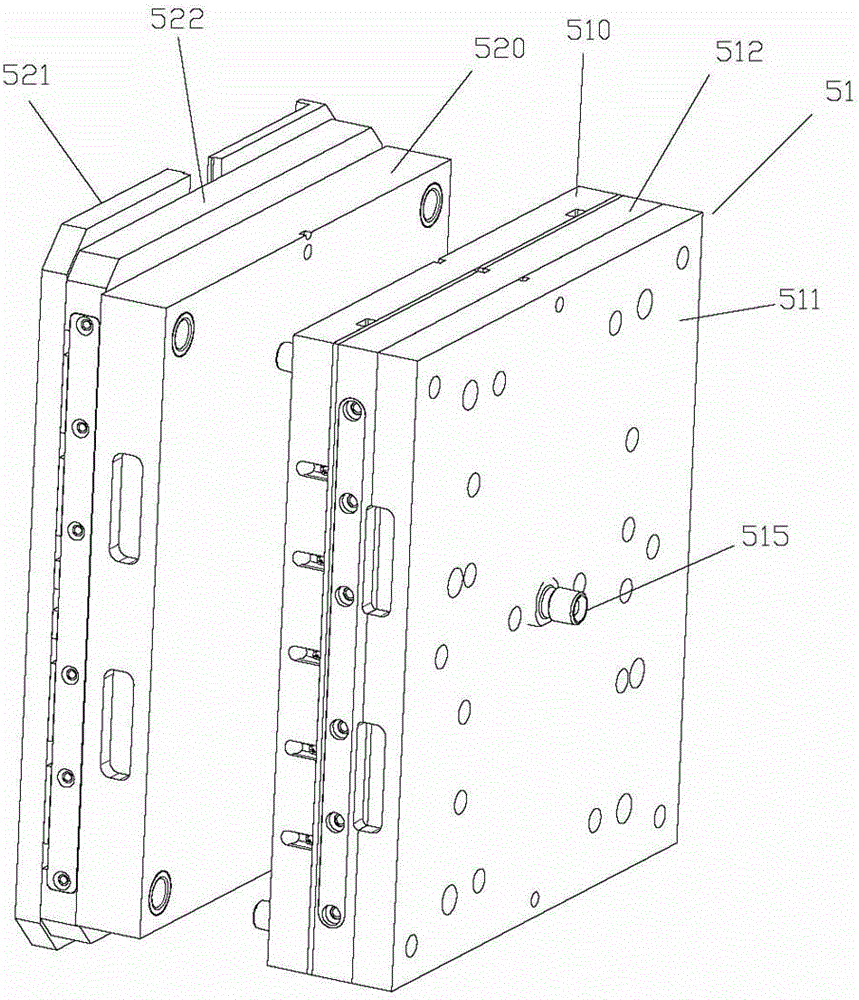

[0022] Such as Figure 1-6 As shown, a kind of automatic meatball machine, comprises machine base 1, is provided with meatball forming mechanism 2, grouting mechanism 3 and controller on described machine base 1, and described meatball forming mechanism 1 comprises mold 5, Mold 5 is fixed on the template, and described template comprises fixed template and moving template 21, and described fixed template is divided into left and right two pieces, and left and right fixed template 221,222 are fixed on support 1, and left and right fixed template 221 , 222 are connected through the guide post 23, the movable template 21 cooperates with the guide post 23 through the guide sleeve, the template driving mechanism 24 drives the movable template 21 to reciprocate along the guide post 23, and the mold 5 includes a fixed mold 51 and a movable mold 52, the fixed mold 51 is fixed on the left fixed template 222, the movable mold 52 is fixed on the movable template 21, and a heat insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com