Structure with expanding rod free of being extracted and pipe expander

A technology of expanding rods and fixing plates, which is applied in the field of tube expanders, can solve the problems of heavy workload and inconvenient replacement of expanding rods, and achieve the effects of reducing workload, simple structure and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

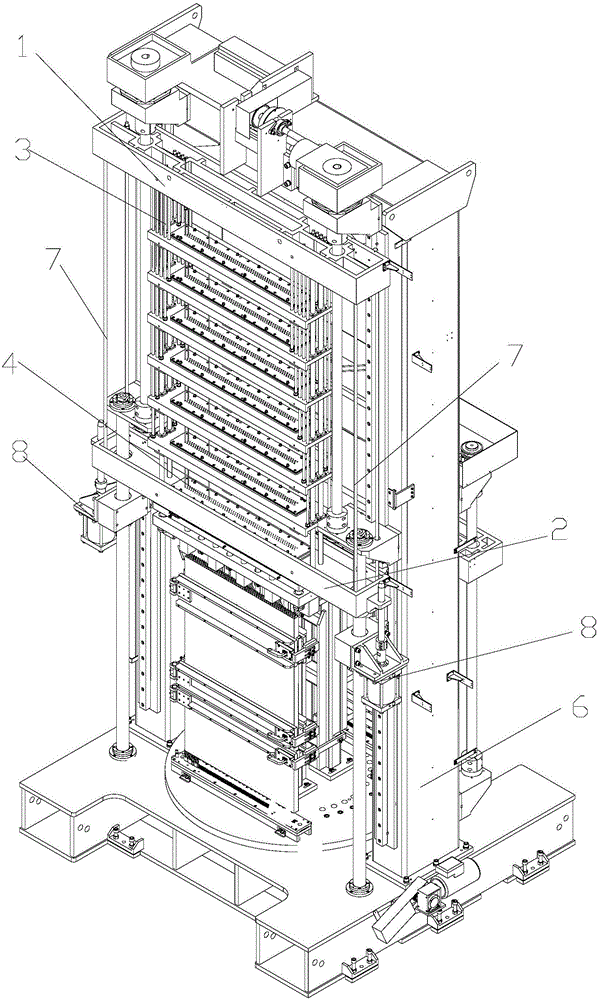

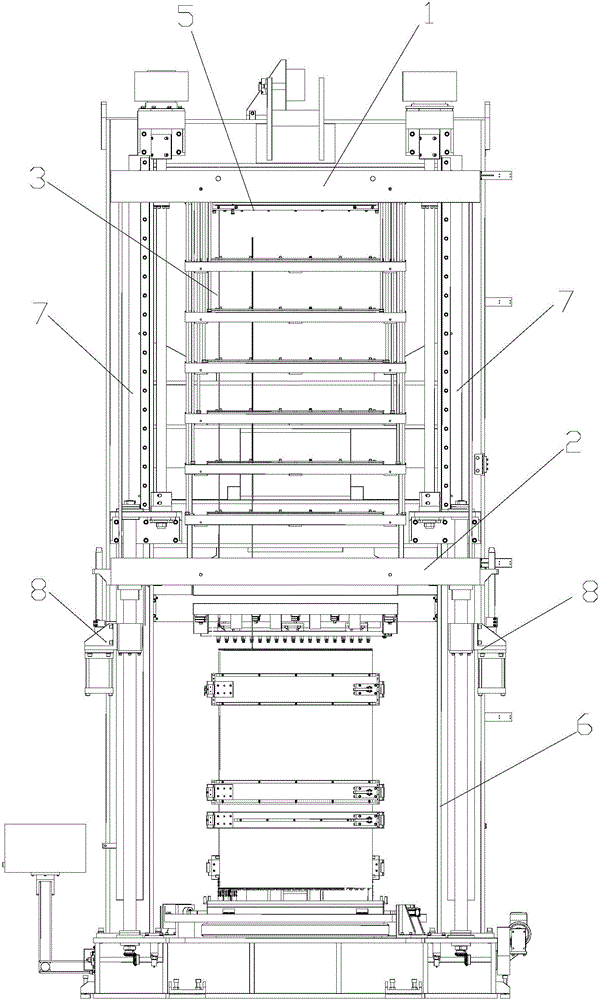

[0022] Examples such as Figures 1 to 7 As shown in the figure, an expansion rod-free structure is installed on the expansion rod machine, which facilitates the switch between the working and non-working of the expansion rod, and does not need to replace the expansion rod repeatedly, thereby reducing the workload and improving efficiency. The rod expander includes a frame 6, a power base 1 arranged on the frame 6, a discharge base 2 connected to the power base 1 through a boom 7, and the frame 6 is fixedly provided with a benchmark under the discharge base 2. Taiwan 8. A group of expansion rods 3 fixed on the power base 1 are also provided. The power seat 1 drives the unloading seat 2 to move up and down, and is limited by the reference table 8 to realize the expansion of the expansion rod to the heat exchanger.

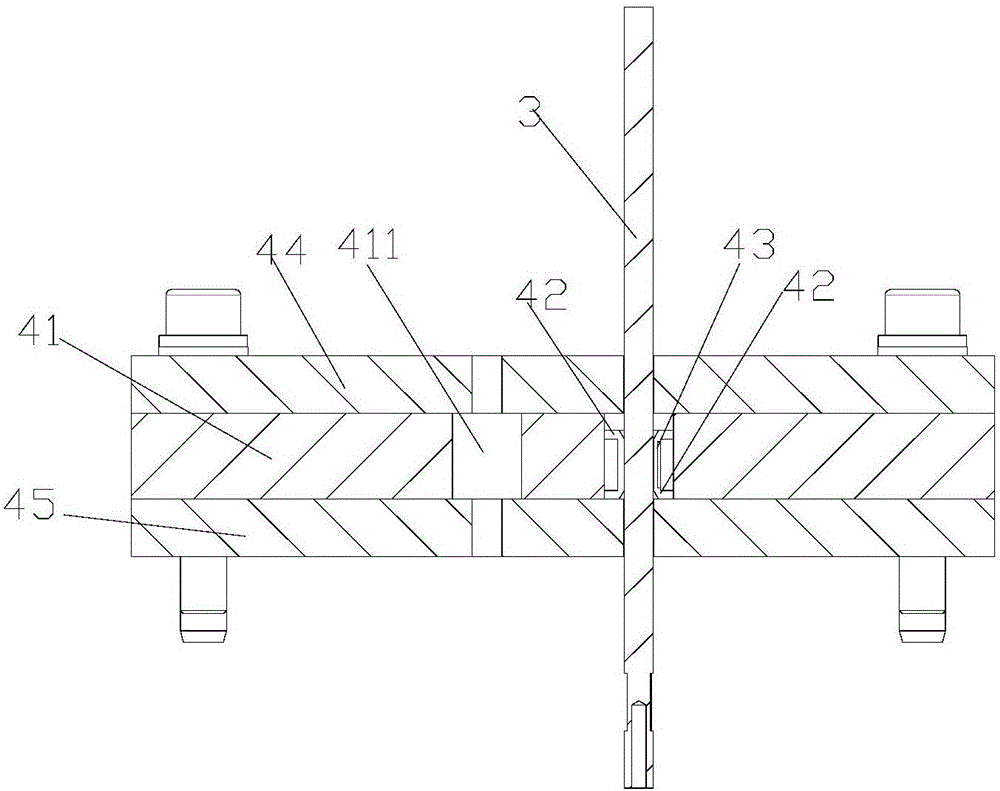

[0023] The expansion rod extraction-free structure includes a power seat 1, a discharge seat 2 and an expansion rod 3, the discharge seat 2 is fixed with an expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com