Welding method of inner rib plates in lower reactor core shell base in high temperature gas cooled reactor

A high-temperature gas-cooled reactor and welding method technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large hardening tendency, great welding difficulty, control of the maximum deformation of the bottom plate, etc., to meet the welding quality. requirements, improve the service life, and the effect of welding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

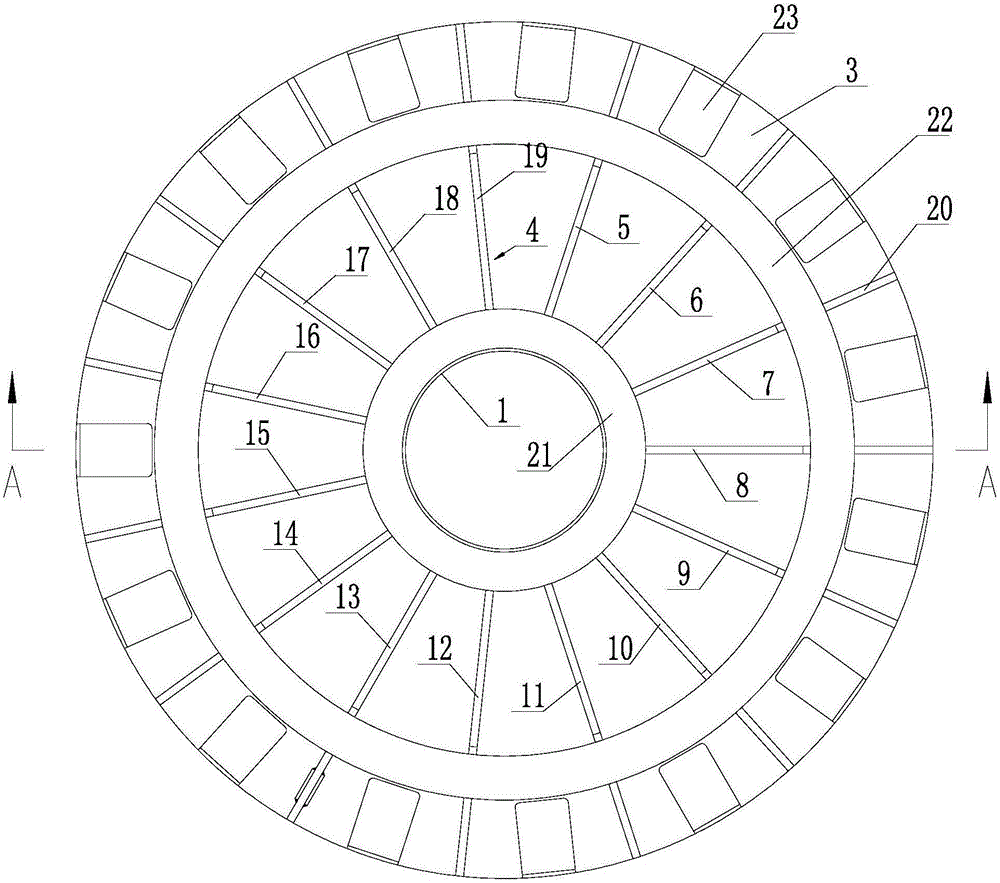

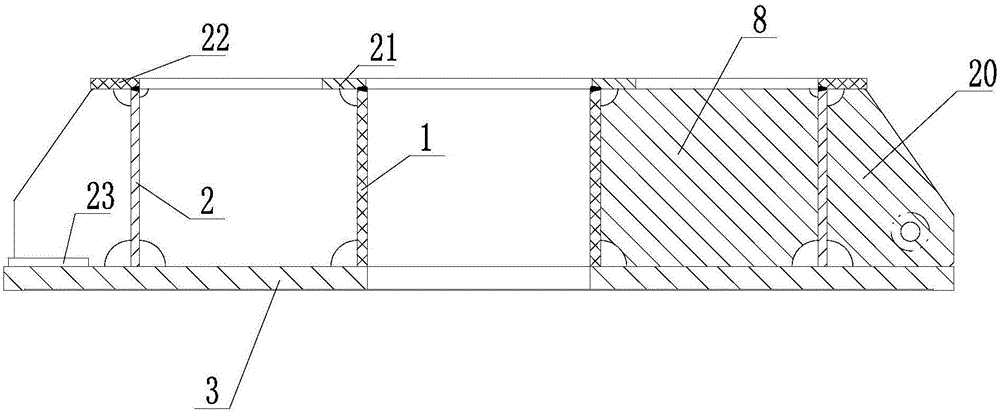

[0019] Such as figure 1 and figure 2As shown, in the welding method of the inner ribs in the base of the lower core shell of the high temperature gas-cooled reactor according to the present invention, after the welding of the inner cylinder 1, the outer cylinder 2 and the bottom plate 3 is completed, 15 inner ribs 4 are evenly distributed After the inner cylinder 1 and the outer cylinder 2, preheat the required welding position until it is above 205°C. The formed preheating area covers the required welding area and extends around. After the preheating area is extended, the inner cylinder 1 , the boundaries on the outer cylinder 2 and the bottom plate 3 are respectively more than 50 mm away from the required welding parts, and the two sides of the inner rib plate 4 are respectively provided with inclined surfaces, and the inclined surfaces of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com