Vacuum electron beam welding method for end face of dissimilar metal electromagnetic valve assembly

A vacuum electron beam and dissimilar metal technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve large thermal stress and tissue stress, increase the difficulty of dissimilar metal welding, and melt welding metallurgical incompatibility And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

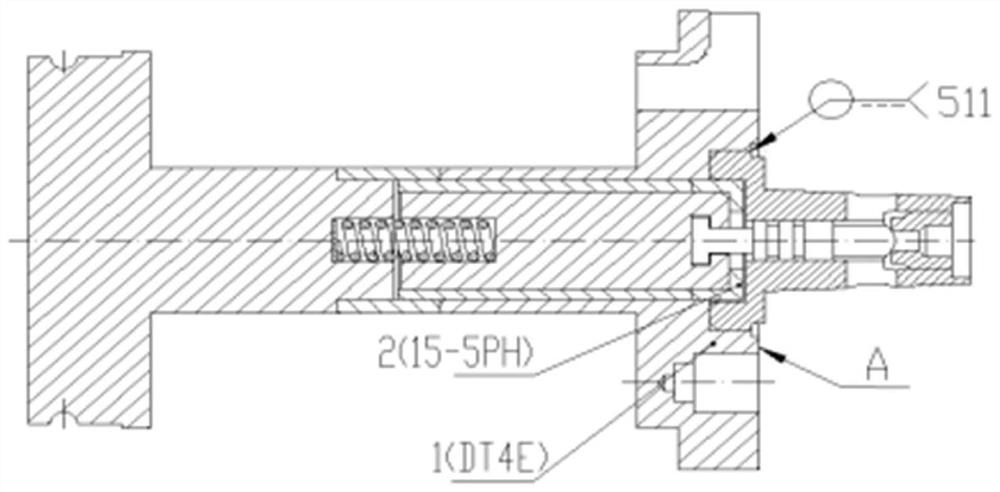

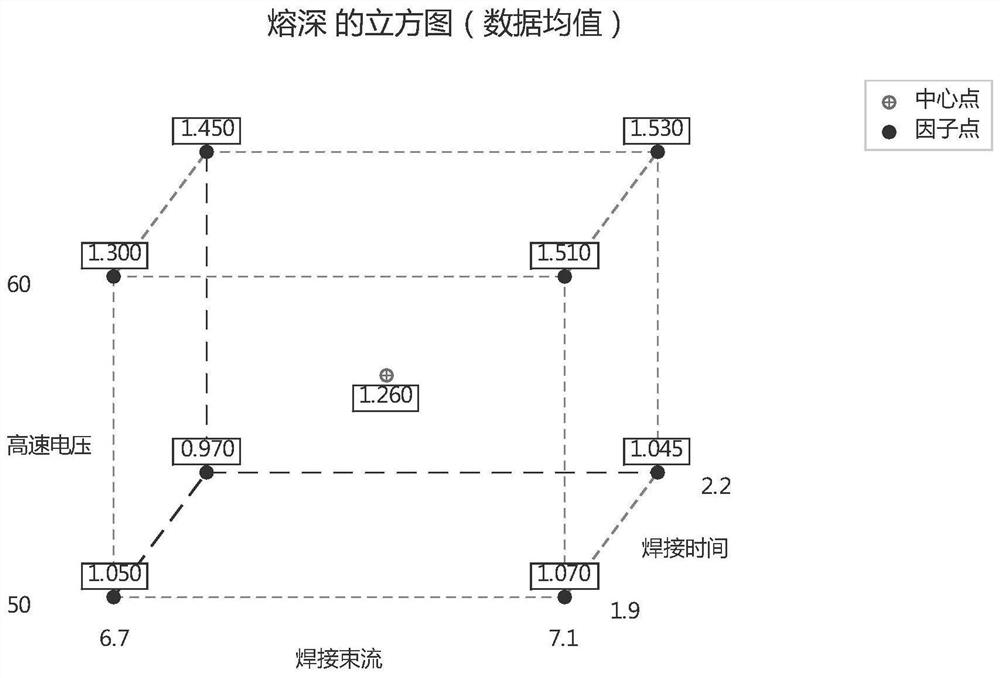

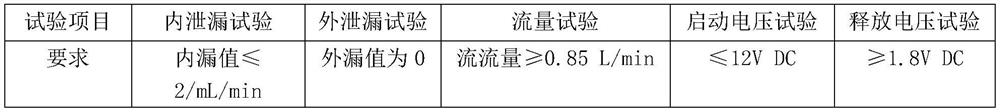

[0021] Embodiment 1 of the present invention: a certain type of dissimilar metal (DT4E, 15-5PH) electromagnetic valve assembly end face vacuum electron beam welding process, the interference fit of the welding parts, the welding seam penetration requirements of 1.4mm ~ 1.7mm, welding The diameter of the seam is about Φ8.7mm, and the width of the weld seam does not exceed the ring groove with a ring width of 0.8mm. Including the following steps:

[0022] 1) soaking and drying:

[0023] Soak the parts in ExxonMobil ISOPAR L solvent-based cleaning agent for 2.5 hours, dry them with compressed air, then put them in a drying oven, T=120°C, t=1.5 hours, and air-cool. The soaking process is mainly to clean off the residue on the surface of the parts with a cleaning agent. Because there is a small hole in the part valve body (15-5PH), the cleaning agent enters the hole during the cleaning process, so a drying box is used to dry the cleaning agent inside. The purpose of this process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com