A horizontal spot welding device for welding the end of a bracket lamp

A technology of spot welding device and bracket lamp, which is applied in the direction of welding/welding/cutting items, welding equipment, resistance welding equipment, etc. It can solve the problems of slow welding speed of manual holding parts, inability to automatically spot weld, and affect quality, etc., and achieves improvement. Welding quality and welding efficiency, good market development value, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

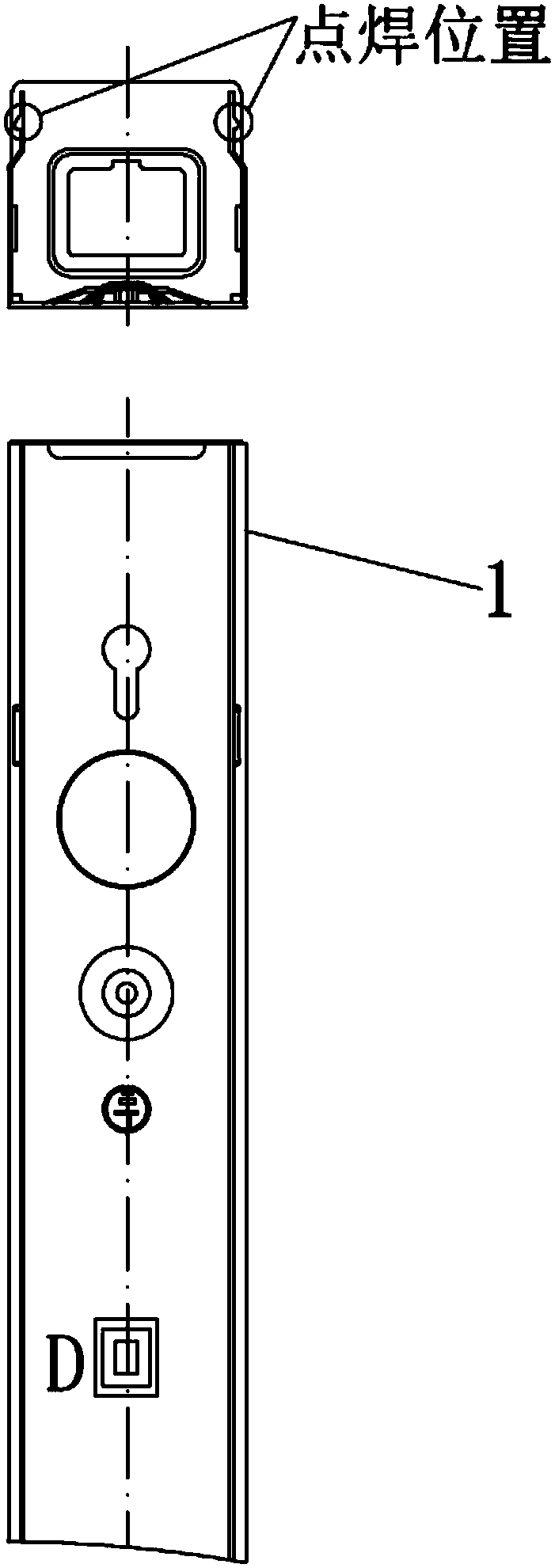

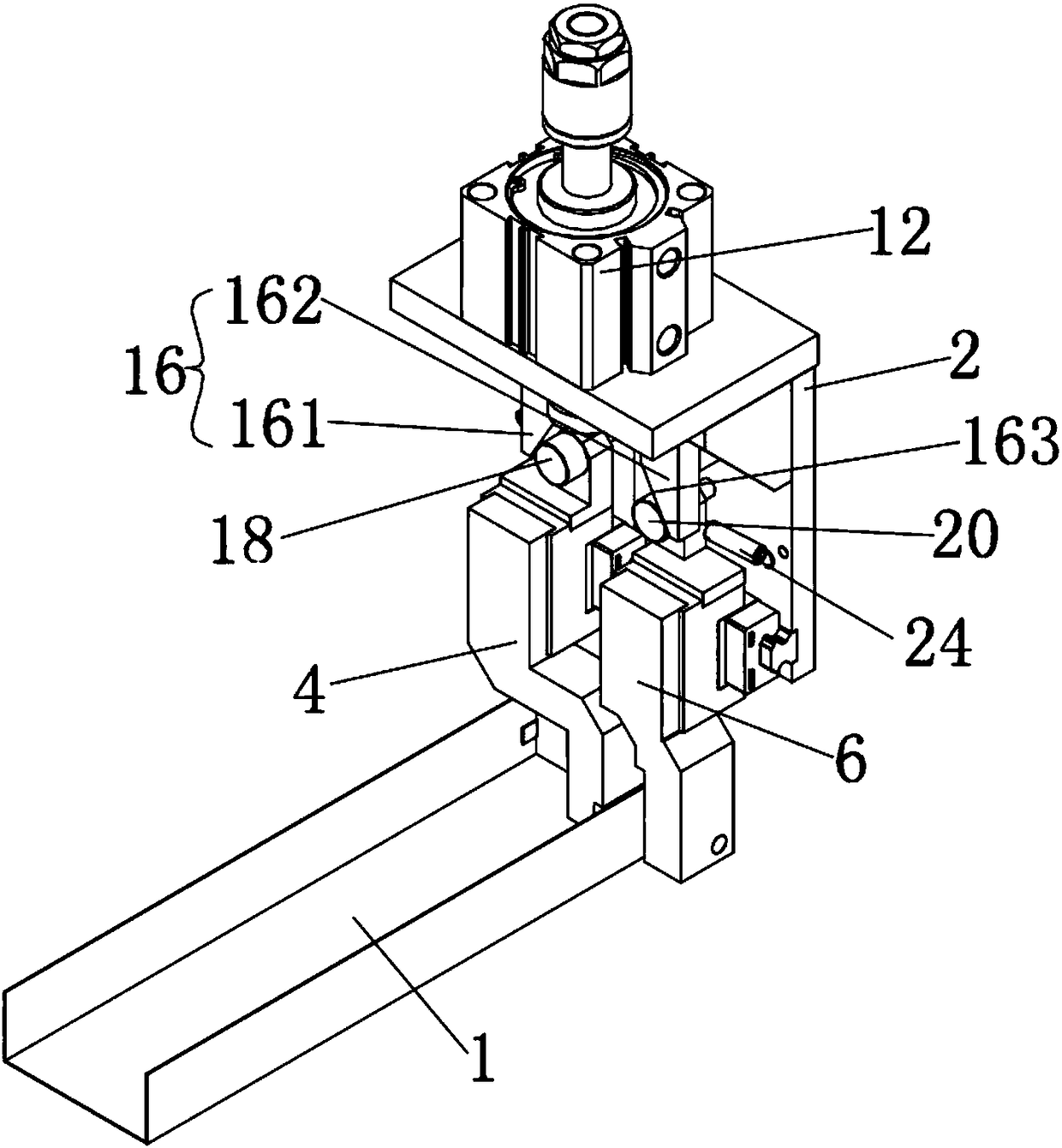

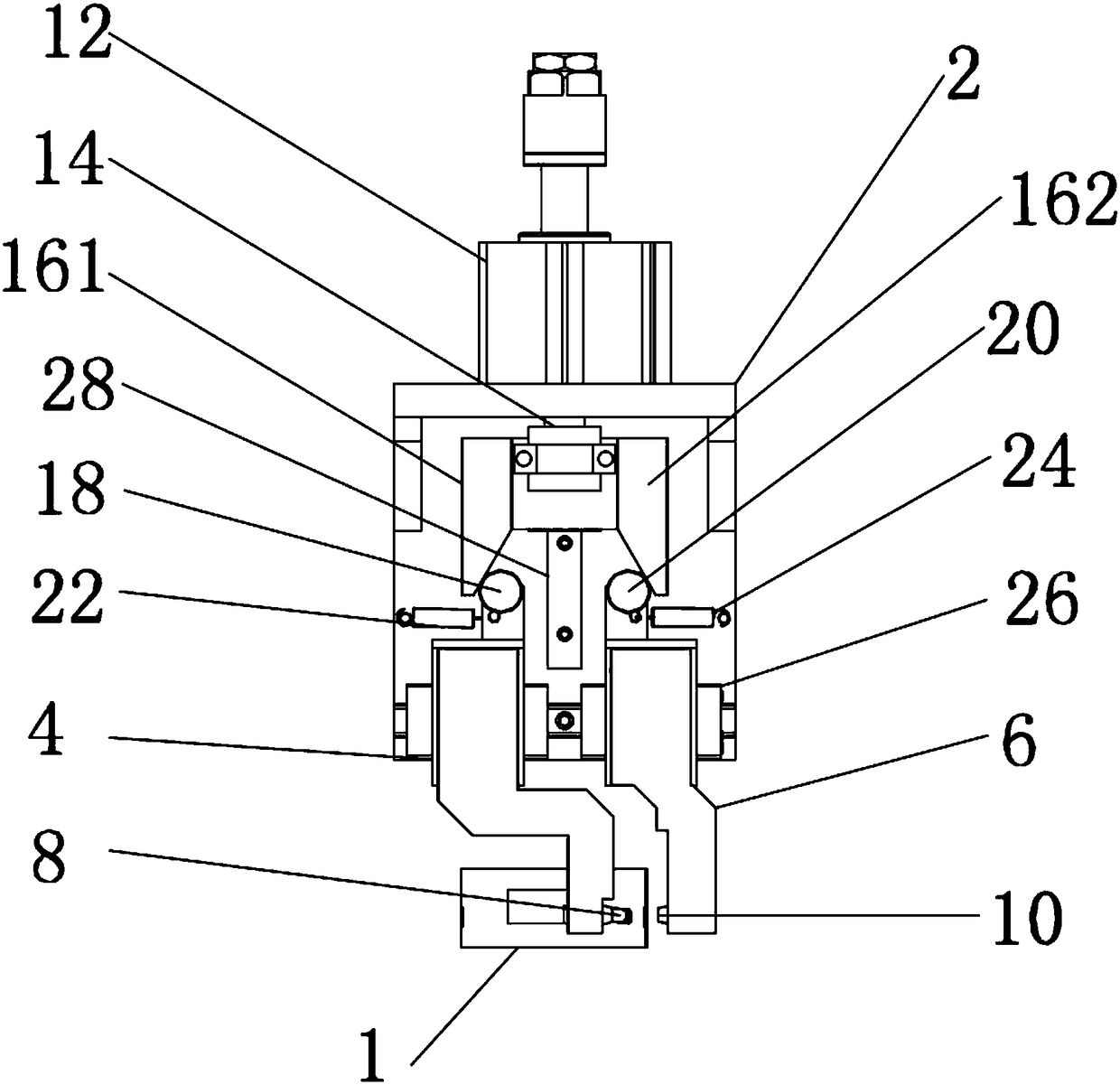

[0024] Such as Figure 2-3 As shown, this embodiment discloses a horizontal spot welding device for welding the end of a bracket lamp, including a fixing frame 2, a first electrode block 4 and a second electrode block 6 separately arranged, and the first electrode The block 4 and the second electrode block 6 are arranged on the fixed frame 2, and the first electrode block 4 and the second electrode block 6 are respectively provided with a first welding head 8 and a second welding head 10, as Figure 4 As shown, both the first electrode block 4 and the second electrode block 6 of the present invention have a shape structure matching the end of the workpiece 1 to be welded, and both the first welding head 8 and the second welding head 10 also have Matching the shape structure of the end of the workpiece 1 to be welded, the gap between the first welding head 8 and the second welding head 10 forms a space for horizontally placing the workpiece to be welded; the first electrode blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com