Ultrasonic mold base machine realizing automatic spot welding

A technology of ultrasonic and mold skin machine, which is applied to bras, clothing, brassiere, etc. It can solve the problems of scalding bra mold skin, low labor efficiency, and inconsistent bonding quality, so as to achieve uniform spot welding quality, save labor and save work. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

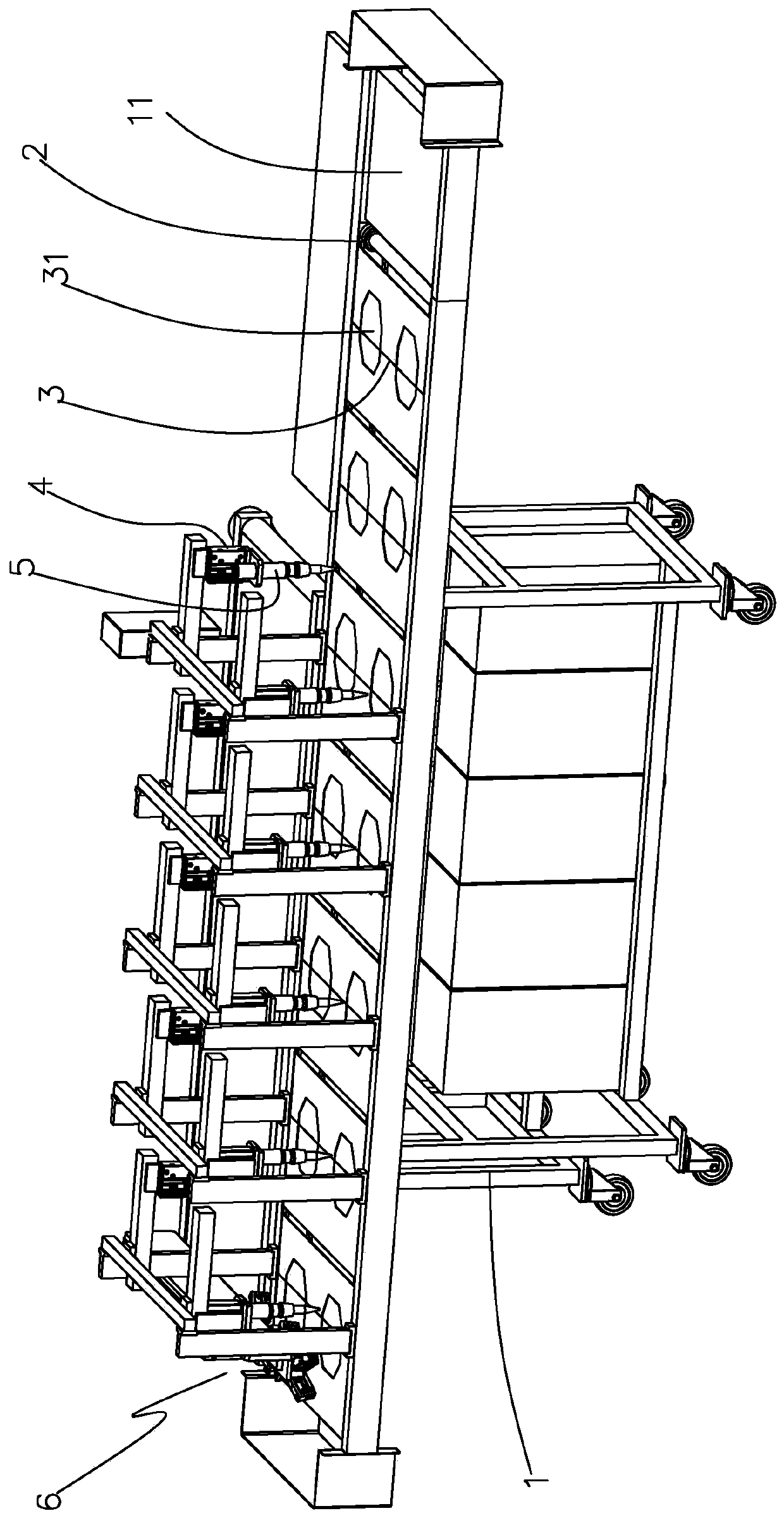

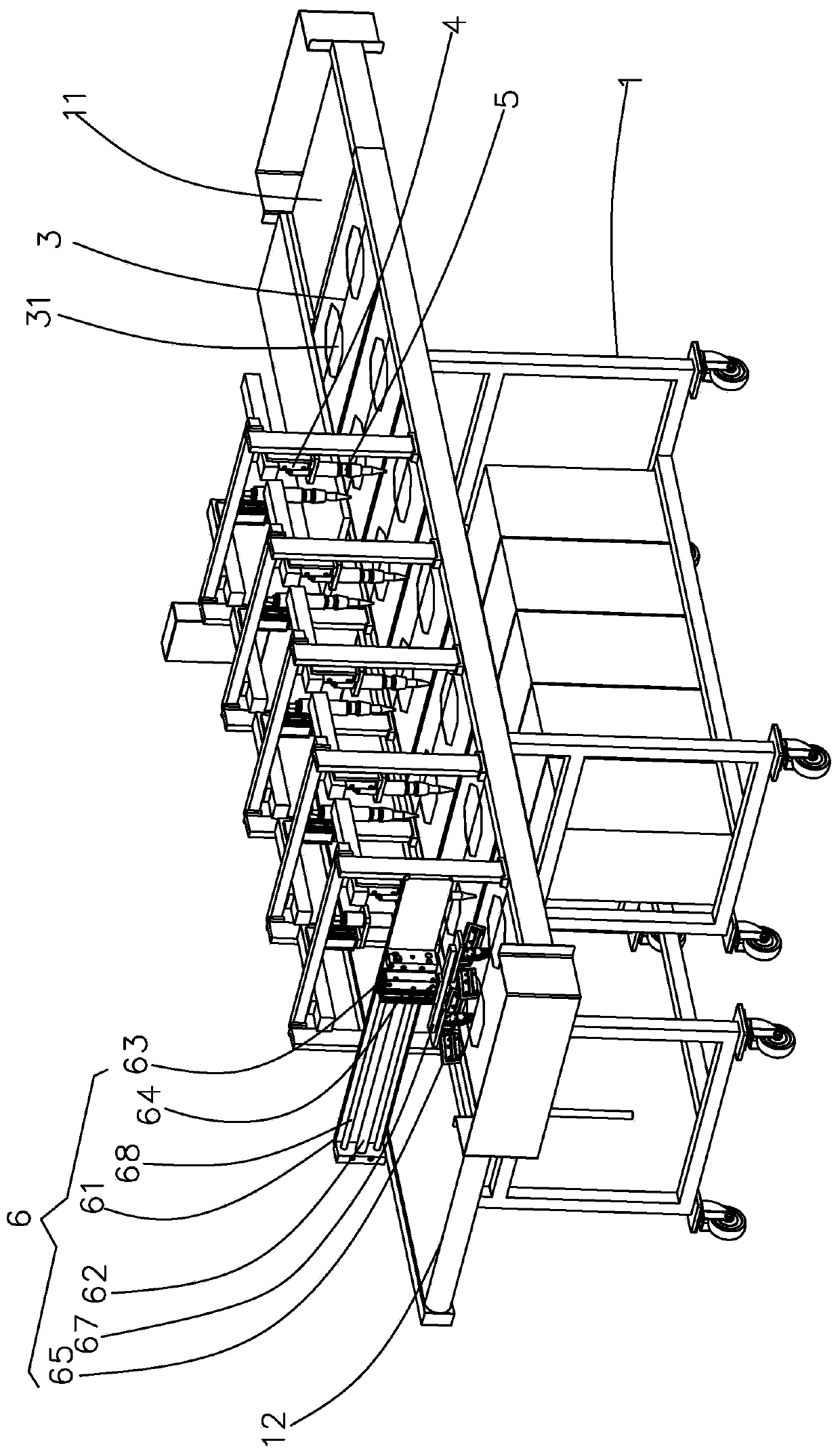

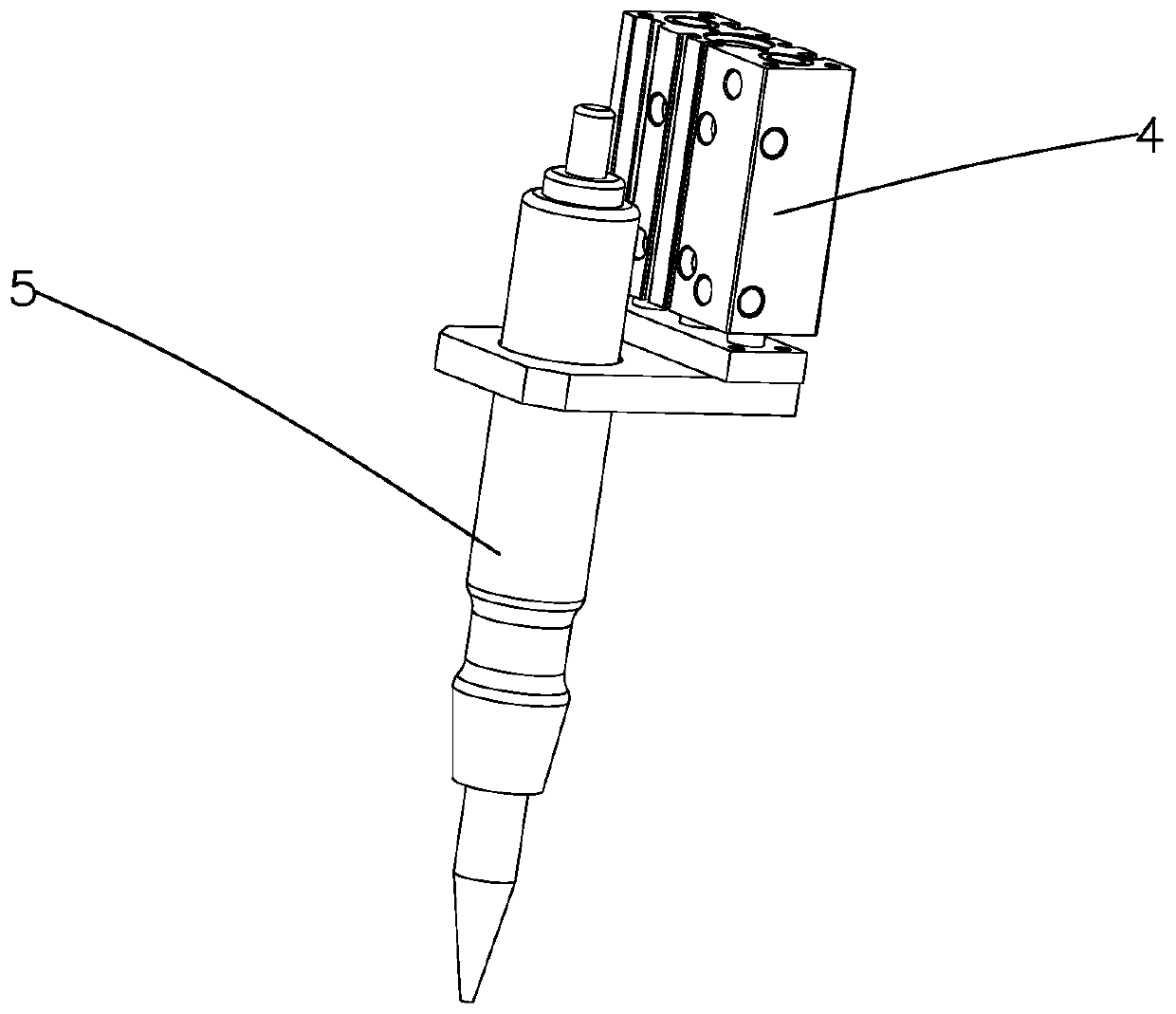

[0030] like Figure 1-5 As shown, the ultrasonic automatic spotting machine of the present invention comprises a frame 1, said frame 1 is provided with a welding conveying track 2, and the front end of the welding conveying track 2 is provided with a working table 11 for placing bra molds to be welded , the rear end side of the welding conveyor track 2 is provided with a stacking platform 12 for stacking bra mold skins that have been spot welded. The welding conveying track 2 is provided with a carrier plate 3 that moves with the welding conveying track 2. The welding conveying track 2 can adopt a chain, and the two ends of the carrier plate are connected to the two chains to rotate with the chain. The carrier plate 3 is provided with a positioning cavity 31 for placing bra membranes, above the welding delivery track 2 and along the welding delivery t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com