A patch type protection board and a battery pack equipped with the protection board

A kind of protective plate, patch technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of large punching area of special nickel tape, loss of competitive price, low production efficiency, etc., to achieve low-cost delivery , The battery structure is simple and reliable, and the effect of reducing spot welding stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

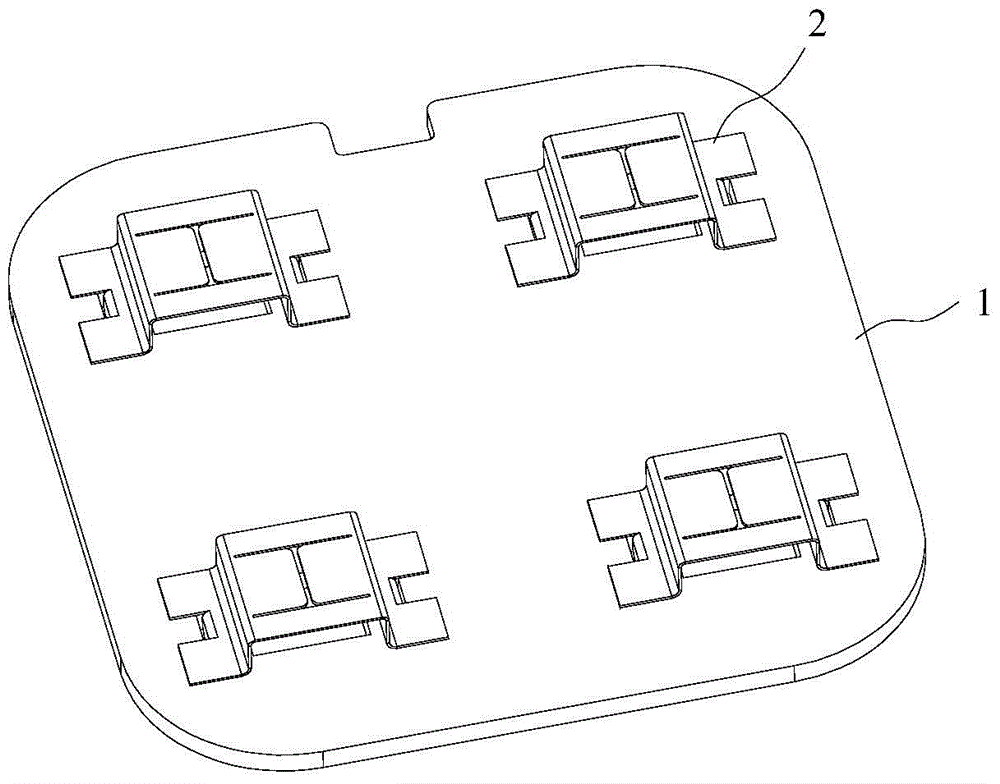

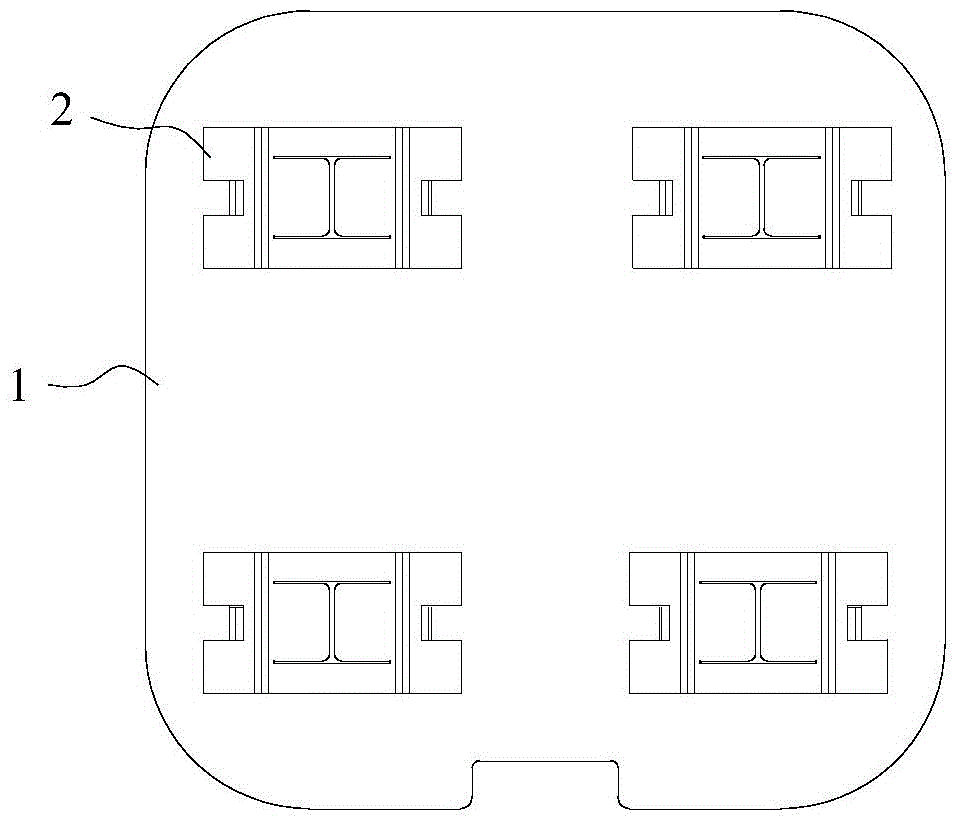

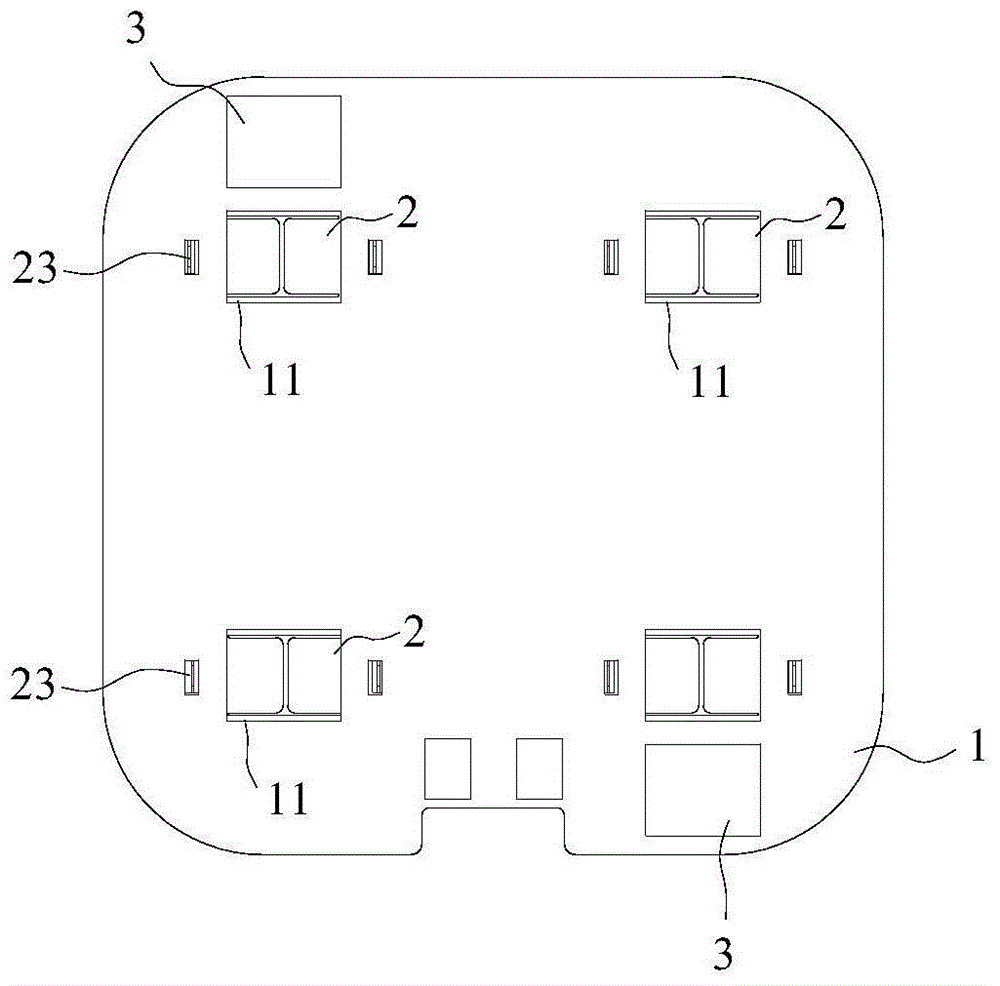

[0023] refer to Figure 1 to Figure 5 , the present invention provides a patch-type protective plate, including a protective plate substrate 1 and several patch nickel strips 2 mounted on the upper side of the protective plate substrate 1, and the middle part of the patch nickel strip 2 forms an upward curved Fold the raised welding portion 21, and the two ends of the patch nickel strip 2 form a welding foot 22 that is attached to and fixed on the surface of the protective plate base material 1, and the welding foot 22 is provided with a pin 23 protruding downward, The welded portion 21 is punched and cut into the welding tongues 24 that are separated in the middle and facing the distribution. The protective plate base material 1 is provided with an opening 11 on the opposite side of the welded portion 21. Both sides of the opening 11 are provided with pin fixing holes for the pins 23 to pass through, and the pins 23 on the solder feet 22 can effectively increase the strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com