Front cover flexible clamp

A flexible fixture and front cover technology, applied in the direction of clamps, manufacturing tools, etc., to achieve the effects of high hardness, space saving, and high reset accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described.

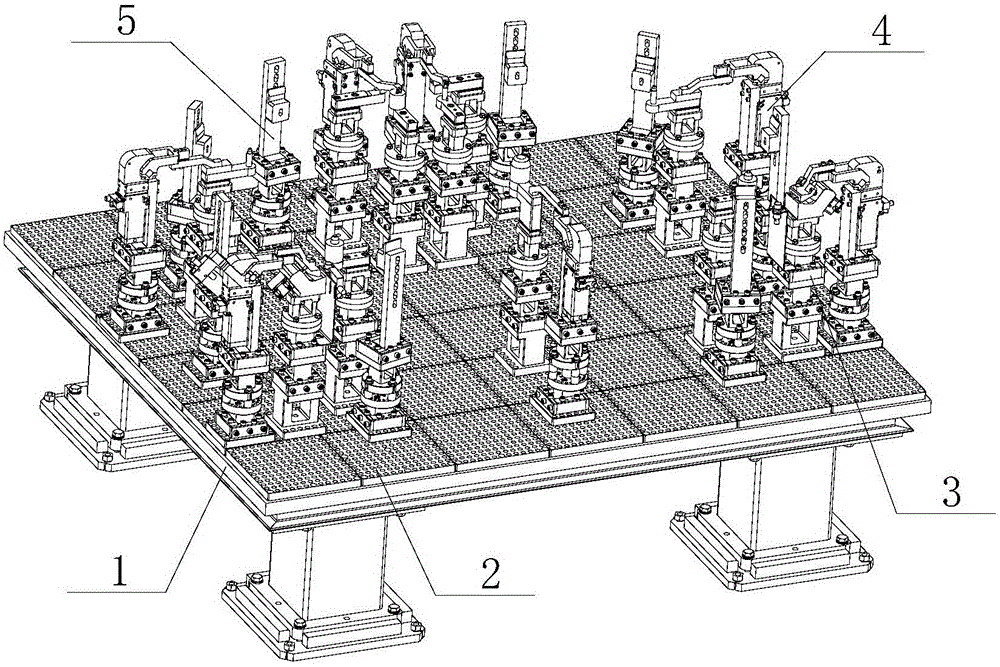

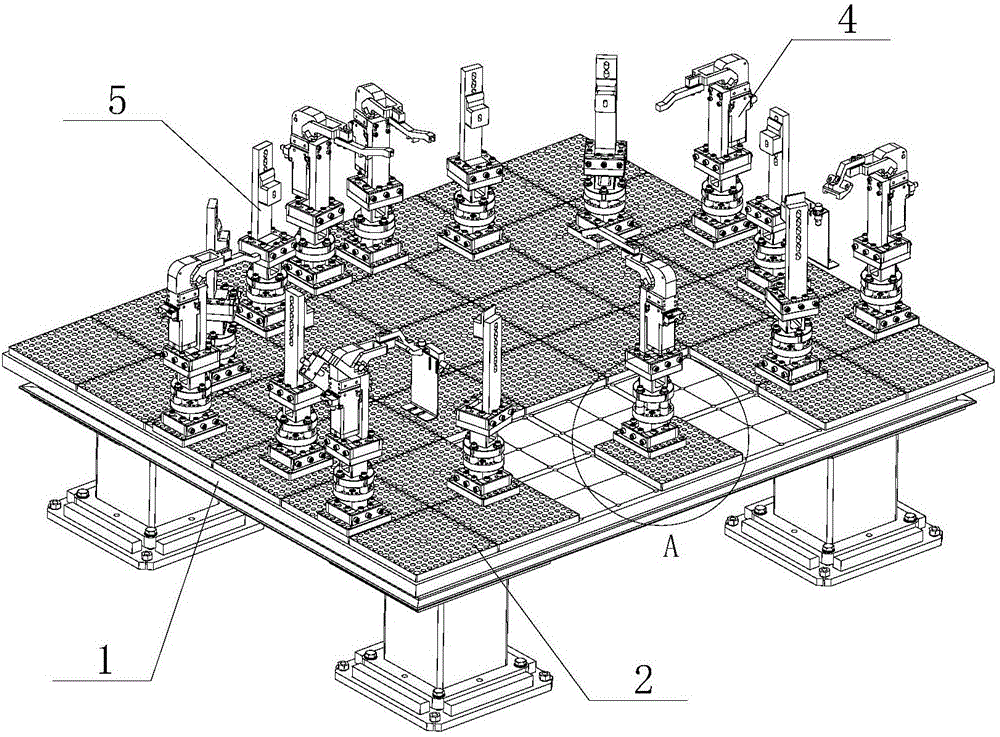

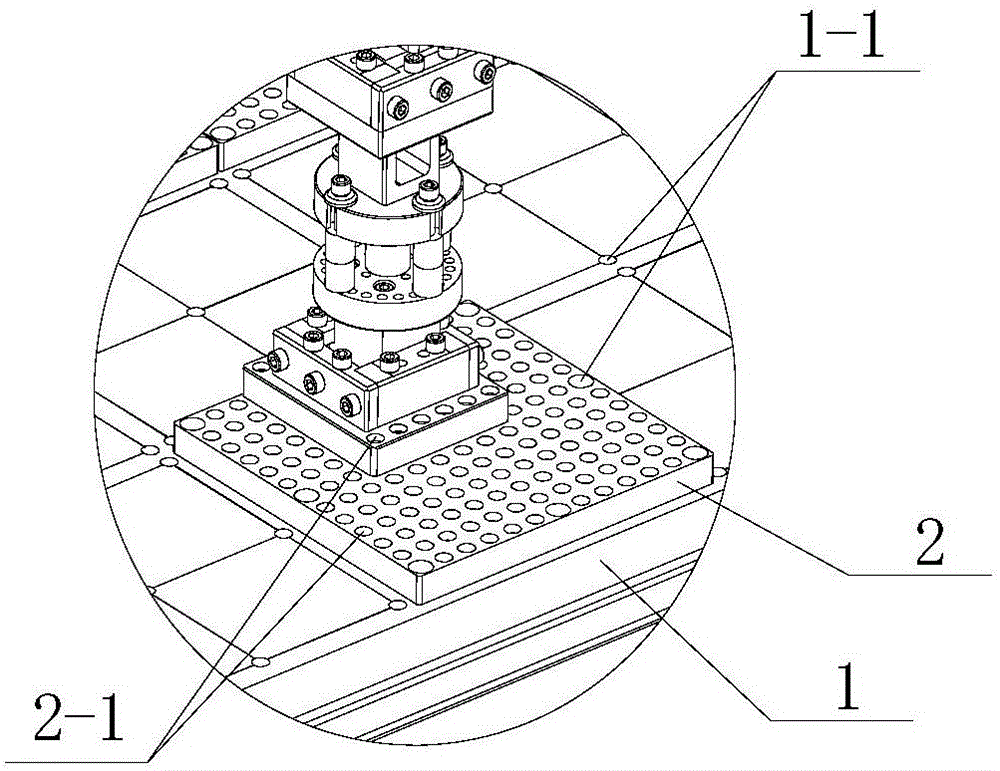

[0027] see Figure 1-4 As shown, the technical solution adopted in this specific embodiment is: it includes a flexible base plate 1, a connection module 2, a support positioning mechanism 3, a cylinder pressing mechanism 4, and a rough positioning mechanism 5; the flexible base plate 1 is rectangular; the flexible base plate 1, parallel to the X and Y axes on the worktable, there are pin-screw coaxial holes-1-1 of the same specification with equal spacing; the pin-screw coaxial hole-1-1 is below the threaded hole; The major diameter of the threaded hole of shaft hole 1-1 is smaller than the diameter of the pin hole by one or several size grades; The pin-screw coaxial holes 1-1 and the pin-screw coaxial holes 2-1 arranged in a matrix form are connected with the flexible base plate 1; several connection modules 2 are laid on the flexible base plate through the pin-screw coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com