Device for producing polystyrene pipeline

A polystyrene and equipment technology, applied in the field of equipment for producing polystyrene pipes, can solve the problems of difficulty in ensuring the quality of pipes, inability to process plastic products, slow flow rate, etc., and achieve safe and reliable work performance, saving production costs, reducing The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0026] Best practice:

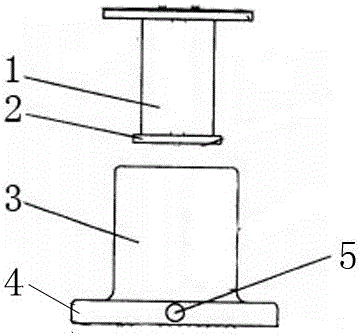

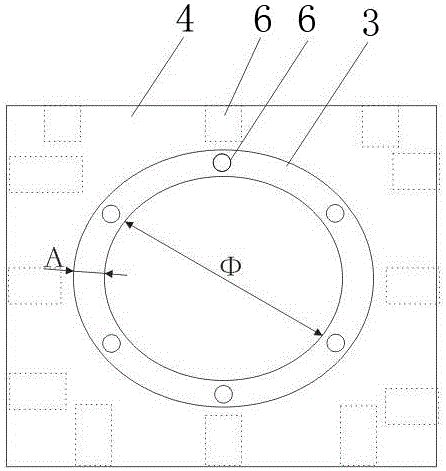

[0027] Such as figure 1 As shown, a kind of equipment for producing polystyrene (PS) pipeline, comprises injection head 1 and injection plastic cylinder 3 below it, and the pressure injection plate 2 is installed at the bottom of described injection head 1, and the bottom of described injection plastic cylinder 3 Set the discharge nozzle 5 and install it on the base 4, the inner diameter of the injection plastic cylinder 3 is φm, the wall thickness is Am, the diameter of the pressure injection plate 2 is φ+A*0.5 / 100~φ+A*1 / 100.

[0028] The inner diameter of the discharge nozzle 5 is φ*1 / 30˜φ*1 / 10.

[0029] The wall thickness A of the plastic injection cylinder 3 is φ*1 / 20˜φ*1 / 10.

[0030] The base plate thickness of the plastic injection cylinder 3 is φ*1 / 10˜φ*1 / 5.

[0031] The downward hydraulic pressure borne by the injection head 1 is φ 2 *10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com