Paper box processing equipment and paper box shaping method

A technology for processing equipment and cartons, which is applied to paper/cardboard containers, carton/carton manufacturing machinery, container manufacturing machinery, etc. It can solve the problems of slow production rhythm, high labor intensity of operators, low work efficiency, etc., and achieve saving Labor force, the effect of reducing the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

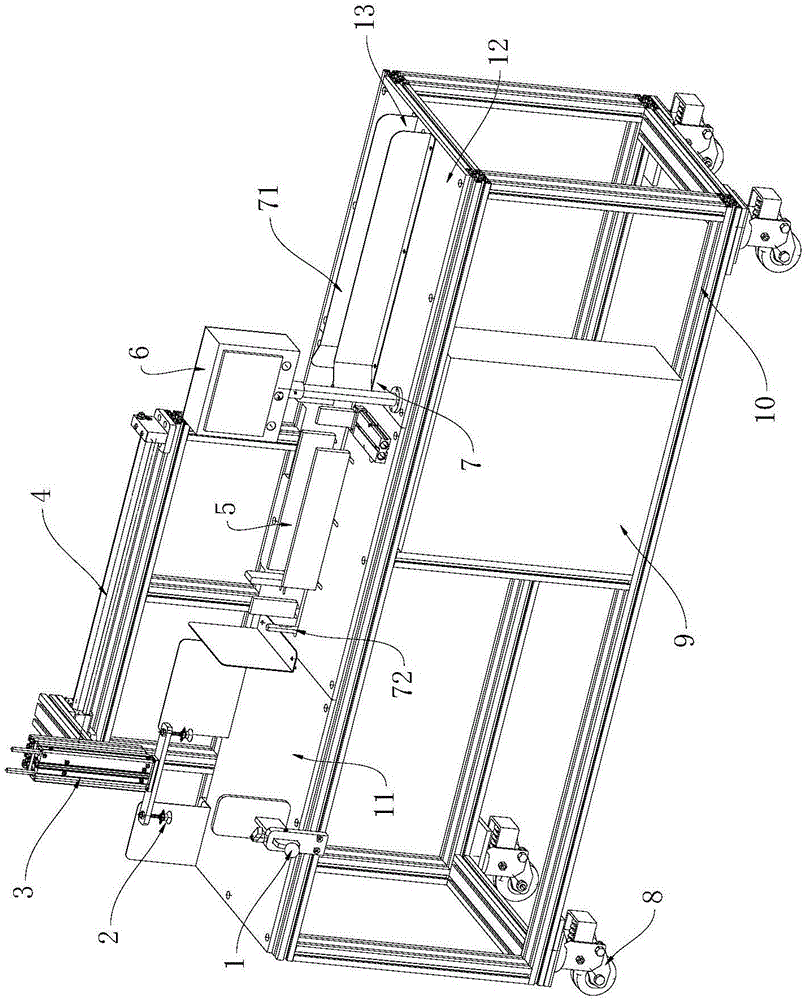

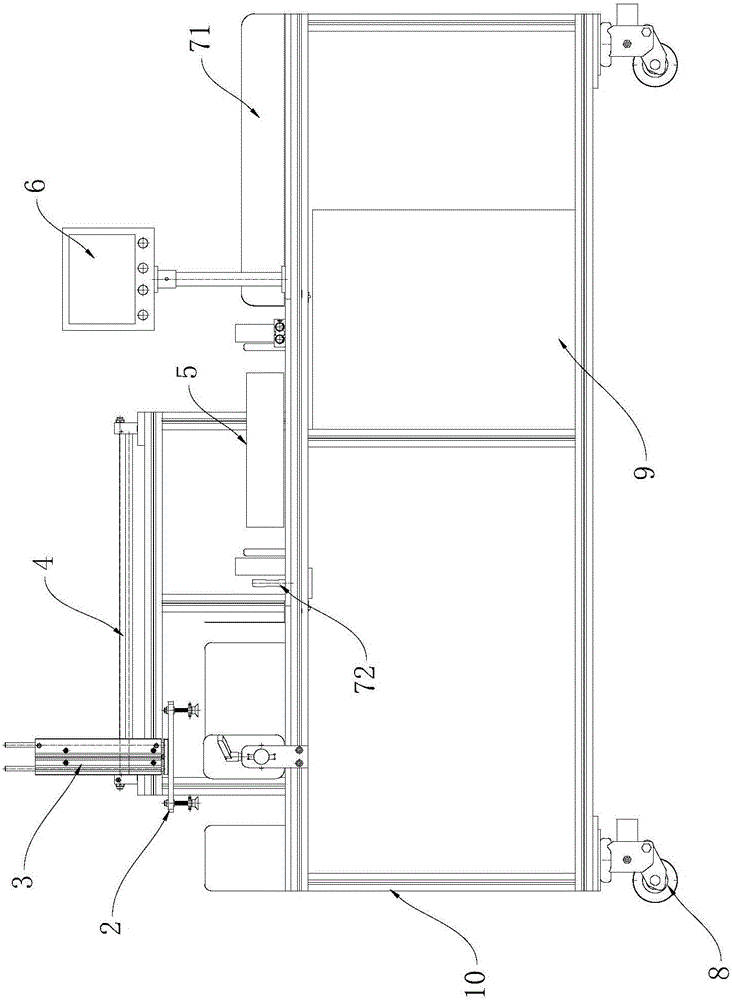

[0035] Such as figure 1 with figure 2 As shown, the converting apparatus for cartons according to the invention is used for folding paper spacers into cartons. The processing equipment for cartons includes a frame 10 , an adsorption component 2 , a conveying mechanism, and a folding mechanism 5 . The frame 10 has a feeding station 11 and a discharging station 12 . The conveying mechanism is connected with the adsorption unit 2 and is used to control the adsorption unit 2 to switch among the feeding station 11 , the folding mechanism 5 and the discharging station 12 . The folding mechanism 5 is used to fold the paper pad placed thereon.

[0036] Specifically, the frame 10 may be formed by a profile frame. The frame 10 has a working platform. The working platform can have a material feeding station 11 and a material discharging station 12, and the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com