Tray with buffer effect

A technology of cushioning and pallets, which is applied to rigid containers, fragile goods packaging, containers, etc., can solve the problem of high damage rate in transportation, achieve the effect of improving impact resistance and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

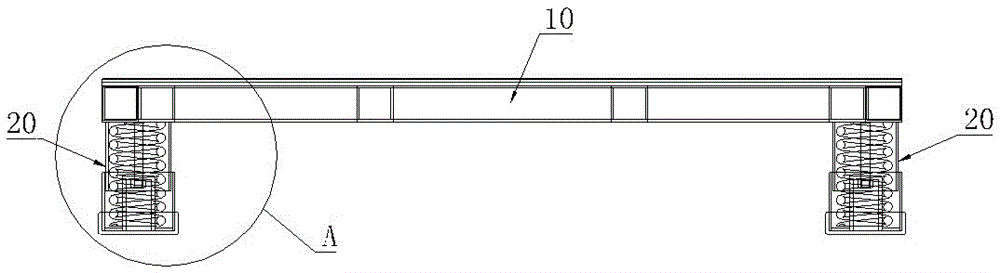

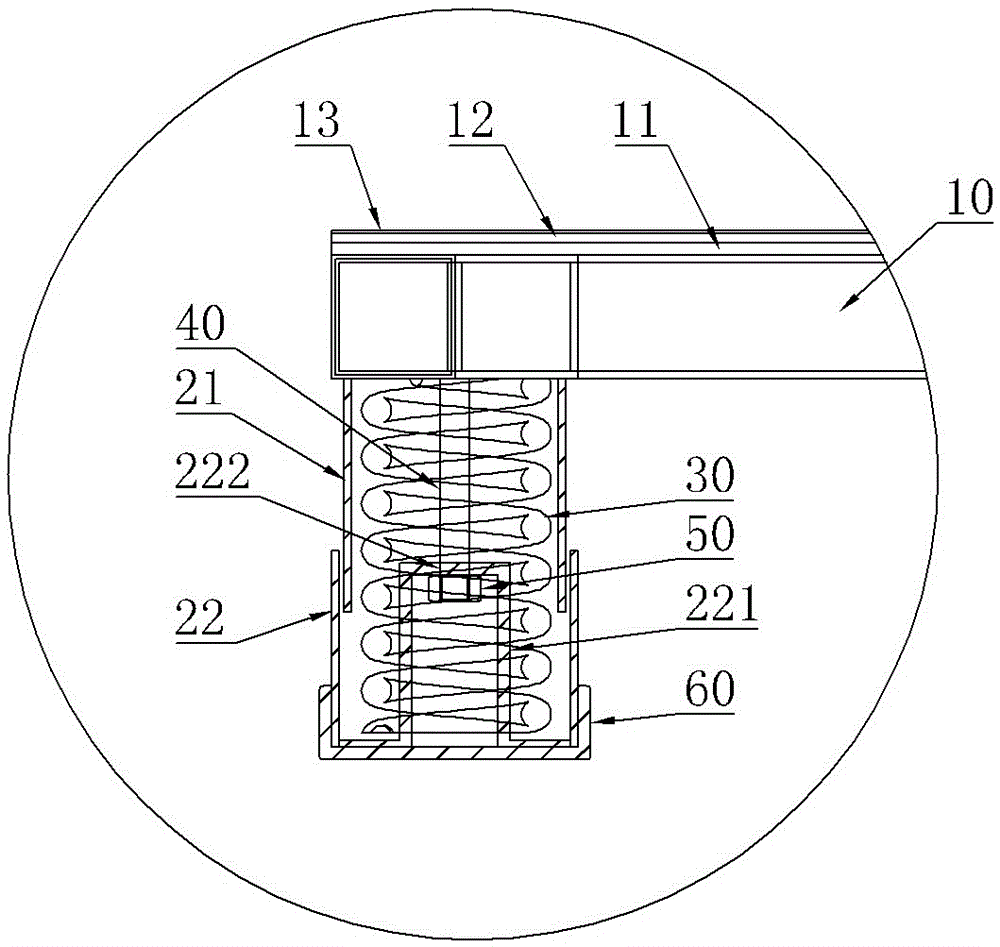

[0016] See figure 1 and figure 2 , a pallet with cushioning effect, which includes a pallet plate 10 and a foot 20 installed on the bottom of the pallet plate 10, the foot 20 includes an upper sleeve 21 and a lower sleeve 22, and the top of the upper sleeve 21 is welded to the bottom surface of the pallet plate 10, the bottom Set in the lower sleeve 22, the upper sleeve 21 and the lower sleeve 22 are also flexibly connected by a buffer structure; the buffer structure includes a buffer spring 30 and a connecting rod 40, and the lower sleeve 22 is provided with an upwardly protruding hollow column 221, the top surface of the hollow column 221 has a through hole 222, the bottom of the connecting rod 40 is provided with threads, the connecting rod 40 is arranged in the upper sleeve 21 and the top of the connecting rod 40 is welded to the bottom surface of the pallet plate 10, and the bottom end wears After passing through the through hole 222, it is threadedly connected with the...

Embodiment 2

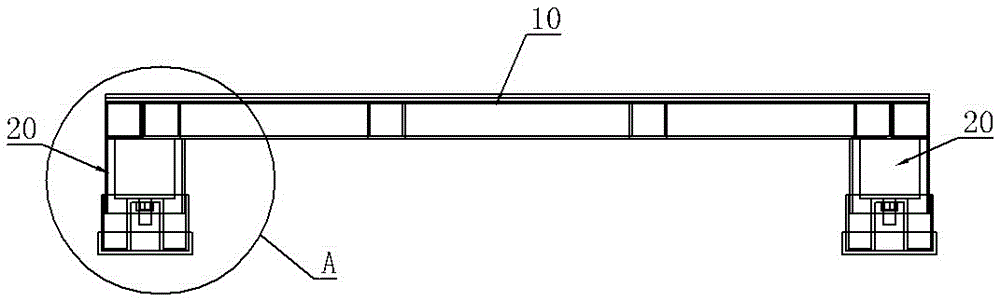

[0018] See image 3 and Figure 4 , the difference from Embodiment 1 is that the buffer structure includes a polyurethane buffer 70, the bottom of which is provided with a screw 71, the lower sleeve 22 is provided with an upwardly protruding hollow column 221, and the top of the hollow column 221 is There is a through hole 222 on the surface, the polyurethane buffer 70 is set in the upper sleeve 21 and its bottom is supported by the top surface of the hollow column 221, and the screw 71 is screwed with the limit nut 50 after passing through the through hole 222 from top to bottom .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com