Integrated utilization device for waste heat

A waste water and heat exchange tube technology, which is applied in energy waste water treatment, lighting and heating equipment, steam/steam condensers, etc., can solve the problems of increasing cost consumption, power consumption, water resource consumption, etc., and achieve self-sufficiency, adaptability Strong capacity and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

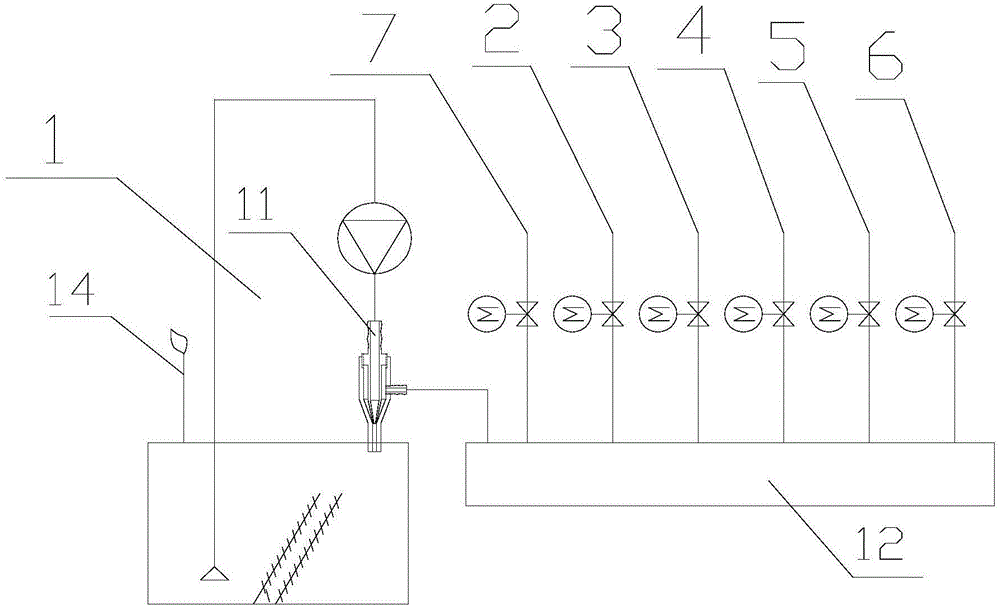

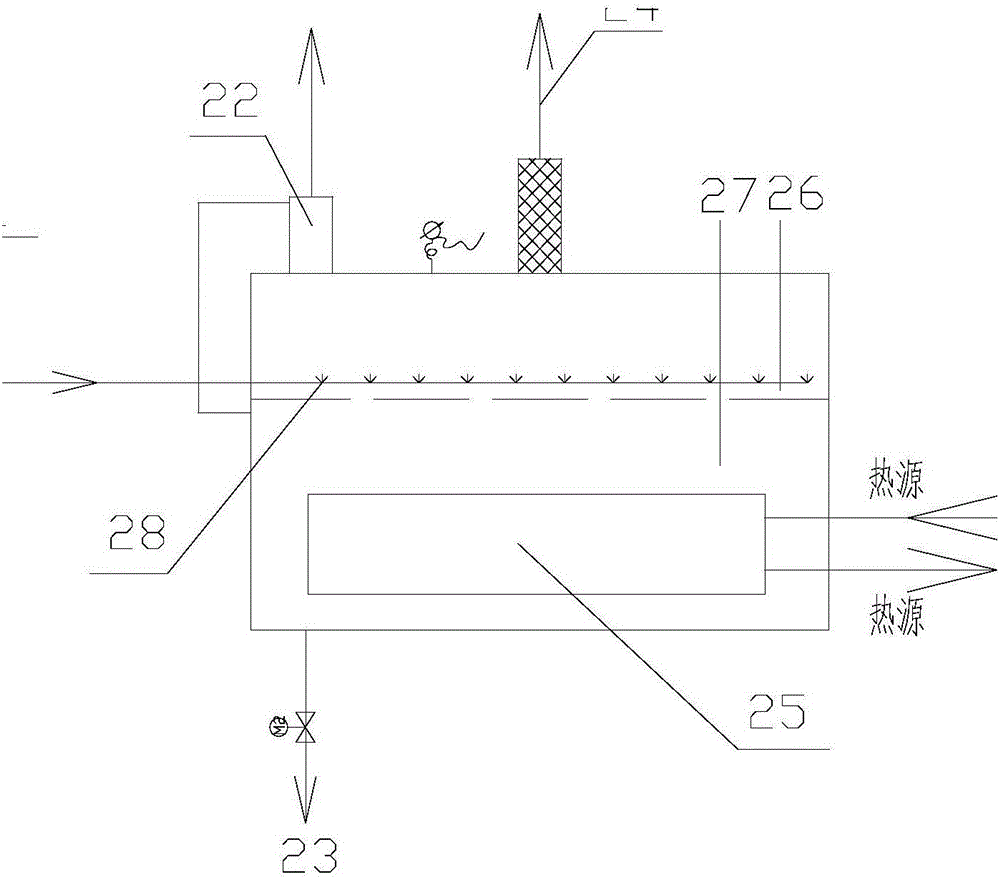

[0035] see Figure 1~5 The waste heat comprehensive utilization device shown includes a vacuum module 1, an evaporation module 2, a condensation module 4, a distilled water extraction module 5 and a waste water discharge module 6; the evaporation module 2, the condensation module 4, the distilled water extraction module 5 and the waste water discharge module 6 respectively The vacuum module 1 is connected, and a certain degree of vacuum is maintained through the vacuum module 1;

[0036] The vacuum module 1 includes a vacuum device 11 and a vacuum tank 12; the vacuum tank 12 is connected to the evaporation module 2, the condensation module 4, the distilled water extraction module 5 and the waste water discharge module 6 through pipelines, and the pipelines are equipped with independent opening and closing. closed valves;

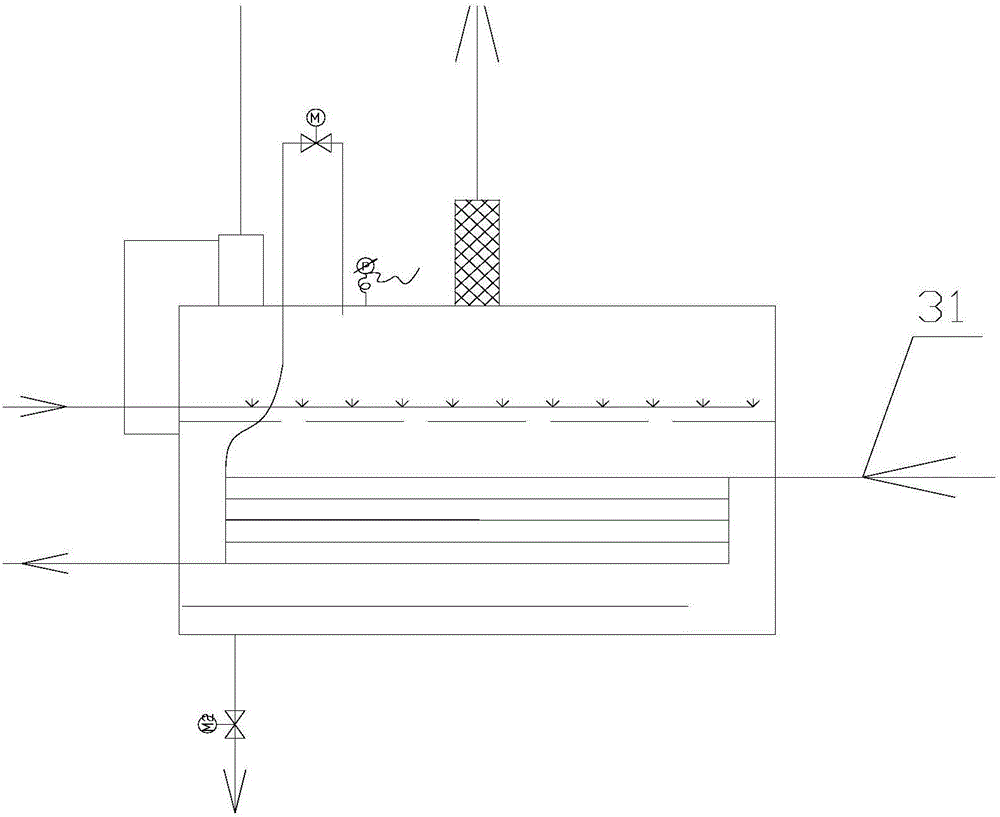

[0037] The condensation module 4 includes a first heat exchange pipeline 41, a second heat exchange pipeline 42, a steam inlet 43, a distilled water extrac...

Embodiment 2

[0044] see Figure 1~7 The waste heat comprehensive utilization device shown includes a vacuum module 1, an evaporation module 2, a second evaporation module 3, a condensation module 4, a distilled water extraction module 5, a waste water discharge module 6 and a negative pressure degassing module 7; the evaporation module 2, the second The evaporation module 3, the condensation module 4, the distilled water extraction module 5 and the waste water discharge module 6 are respectively connected with the vacuum module 1, and a certain degree of vacuum is maintained through the vacuum module 1;

[0045] The vacuum module 1 includes a vacuum making device 11 and a vacuum tank 12; the vacuum tank 12 is respectively connected with the evaporation module 2, the second evaporation module 3, the condensation module 4, the distilled water extraction module 5 and the waste water discharge module 6 through pipelines. Equipped with valves that can be opened and closed independently;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com