Easy-processing and halogen-free flame retardant thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and easy-to-process technology, which is applied in the field of easy-to-process halogen-free flame-retardant thermoplastic polyurethane elastomer and its preparation, can solve the problem of reducing the mechanical properties of materials such as tensile strength and elongation at break, so as to reduce sensitivity and improve Ease of processability and effects of small fluctuations

Inactive Publication Date: 2017-01-04

SUZHOU HENGLI COMM MATERIAL

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the flame retardancy of thermoplastic polyurethane in the prior art requires the addition of a large amount of halogen-free flame retardants, which often s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Login to View More

Abstract

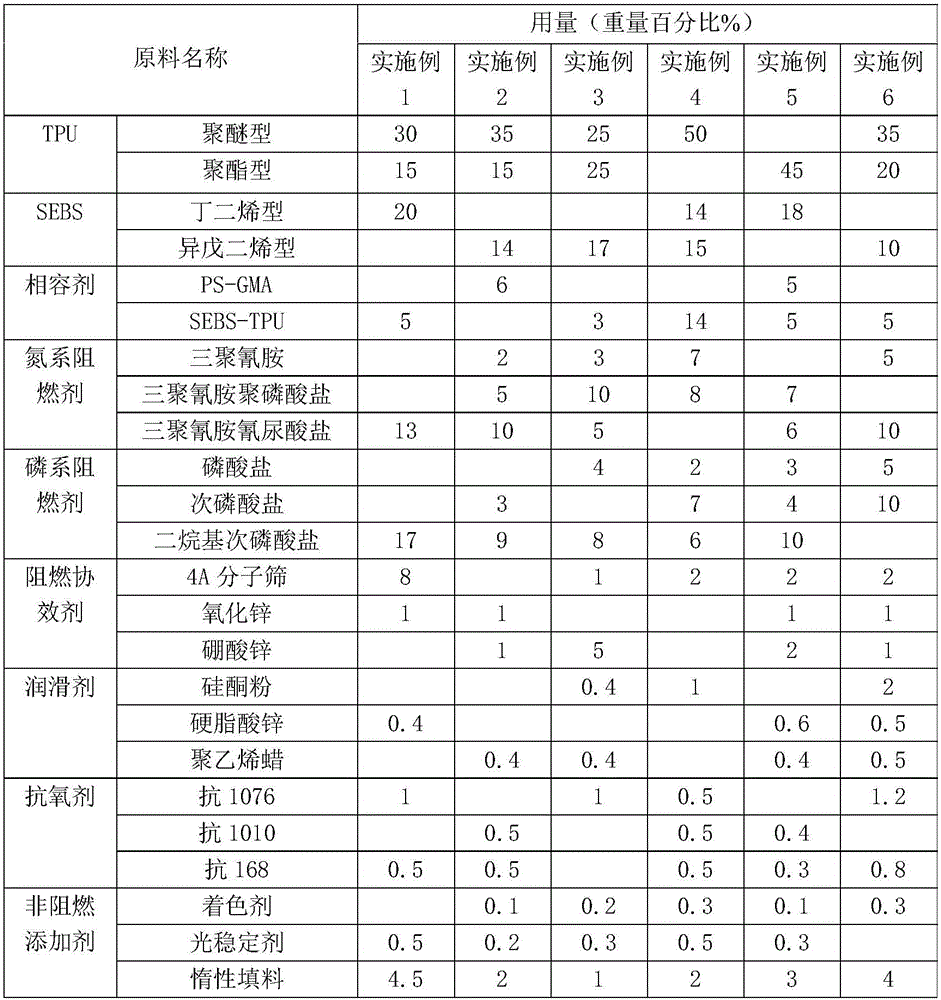

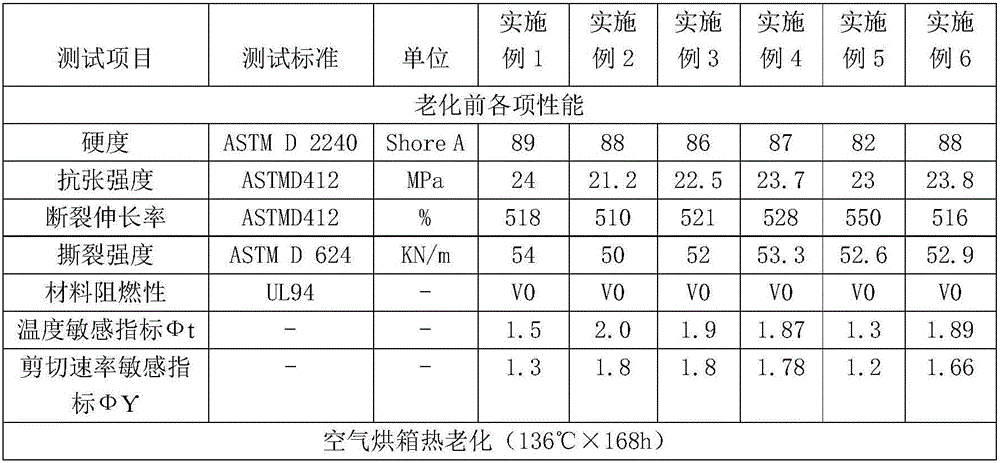

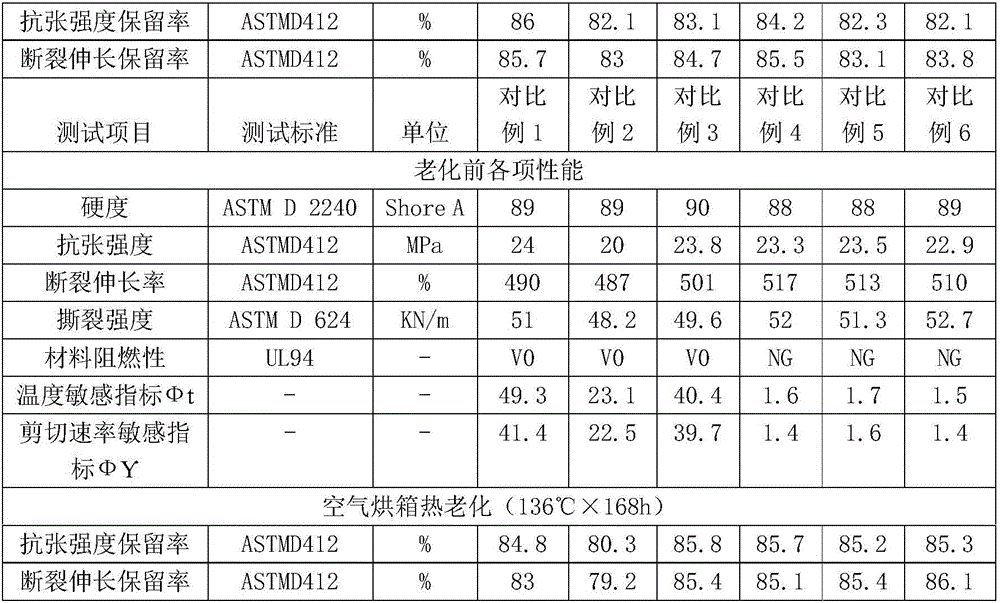

The invention relates to an easy-processing and halogen-free flame retardant thermoplastic polyurethane elastomer and a preparation method thereof. The easy-processing and halogen-free flame retardant thermoplastic polyurethane elastomer is prepared from, by weight, 30-80% of thermoplastic polyurethane resin, 5-30% of a processing modifier, 0.5-15% of a compatilizer, 10-30% of halogen-free flame retardant, 1-10% of flame retardant synergist, 0.5-3% of lubricant, 0.1-2% of antioxygen and 0-5% of non flame-retardant additives. With the method, V0 flame-retardant level 80-90A in hardness, tensile strength larger than or equal to 20Mpa, tear strength larger than or equal to 50KN/m and 3mm in Ul94 standard thickness is obtained according to different thermoplastic polyurethane composites, easiness in processing is achieved, and viscosity is small in change with fluctuation of temperature and shearing speed.

Description

technical field [0001] The invention relates to an easy-to-process halogen-free flame-retardant thermoplastic polyurethane elastomer and a preparation method thereof. Background technique [0002] Thermoplastic polyurethane elastomer, referred to as TPU, has excellent elongation recovery, cold resistance, oil resistance, abrasion resistance, bending resistance, ozone aging resistance and other characteristics, and its wear resistance is second to none. It is widely used in industry, automobile industry, shoe industry, wire and cable and other industries. However, the processing temperature range of TPU is very narrow. Under a certain temperature and shear rate, small fluctuations in temperature and shear rate will cause sharp changes in viscosity, resulting in very unstable quality of extruded products and seriously affecting product quality. In addition, thermoplastic polyurethane has poor flame retardancy. Once burned, the flame will be very violent and accompanied by thi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L75/08C08L75/06C08L53/02C08K13/02C08K5/3492C08K3/34C08K3/22C08K3/38B29C47/92B29C48/92

CPCB29C48/92B29C2948/9258C08K2201/014C08L75/06C08L75/08C08L2201/02C08L2201/22C08L2205/025C08L2205/035C08L2207/04C08L53/025C08K13/02C08K5/34928C08K3/34C08K2003/2296C08K5/34922C08K2003/387

Inventor 何晓东廖永江马慧婷

Owner SUZHOU HENGLI COMM MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com