Municipal drainage axial flow pump maintenance trial run control device

A technology of urban drainage and control devices, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as inconvenient maintenance operations, and achieve the effect of reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, in conjunction with the accompanying drawings, a preferred embodiment is described in detail to further illustrate the present invention.

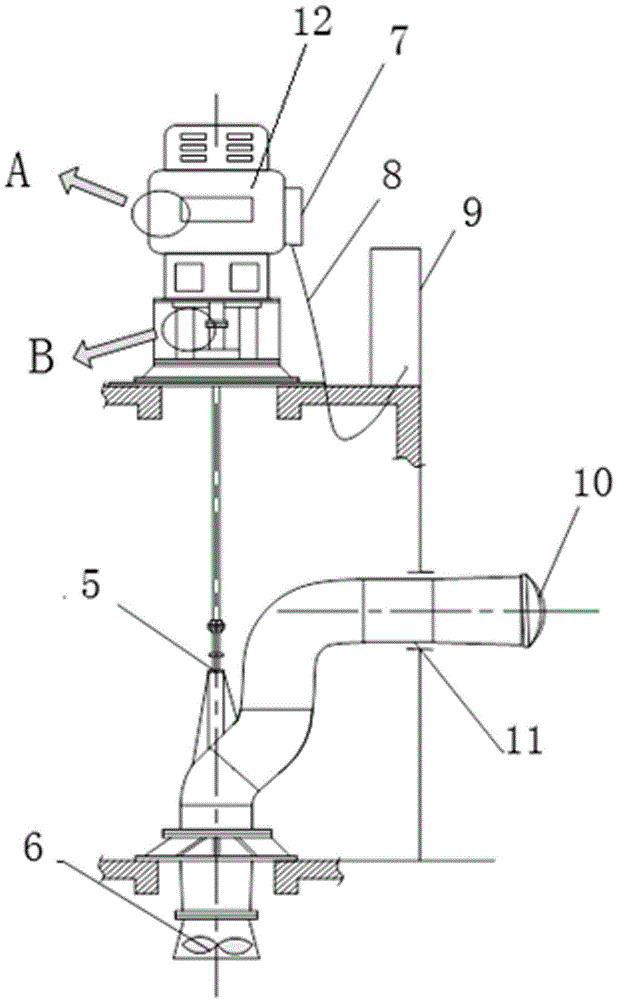

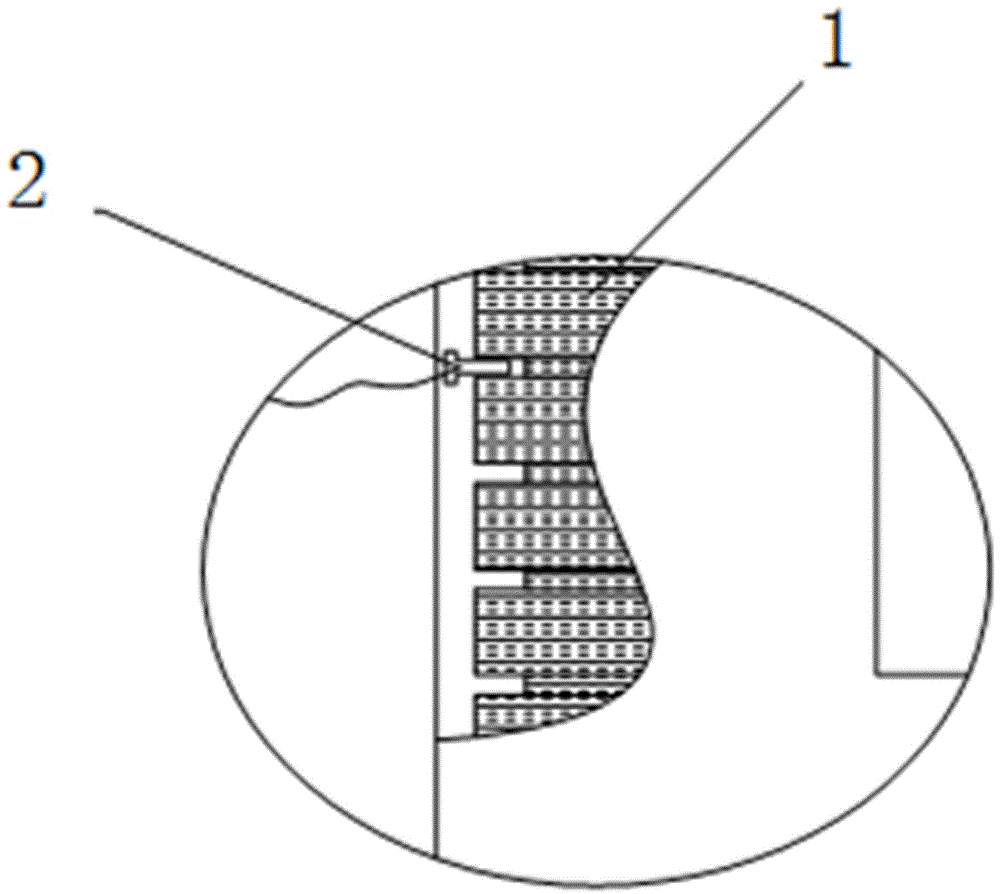

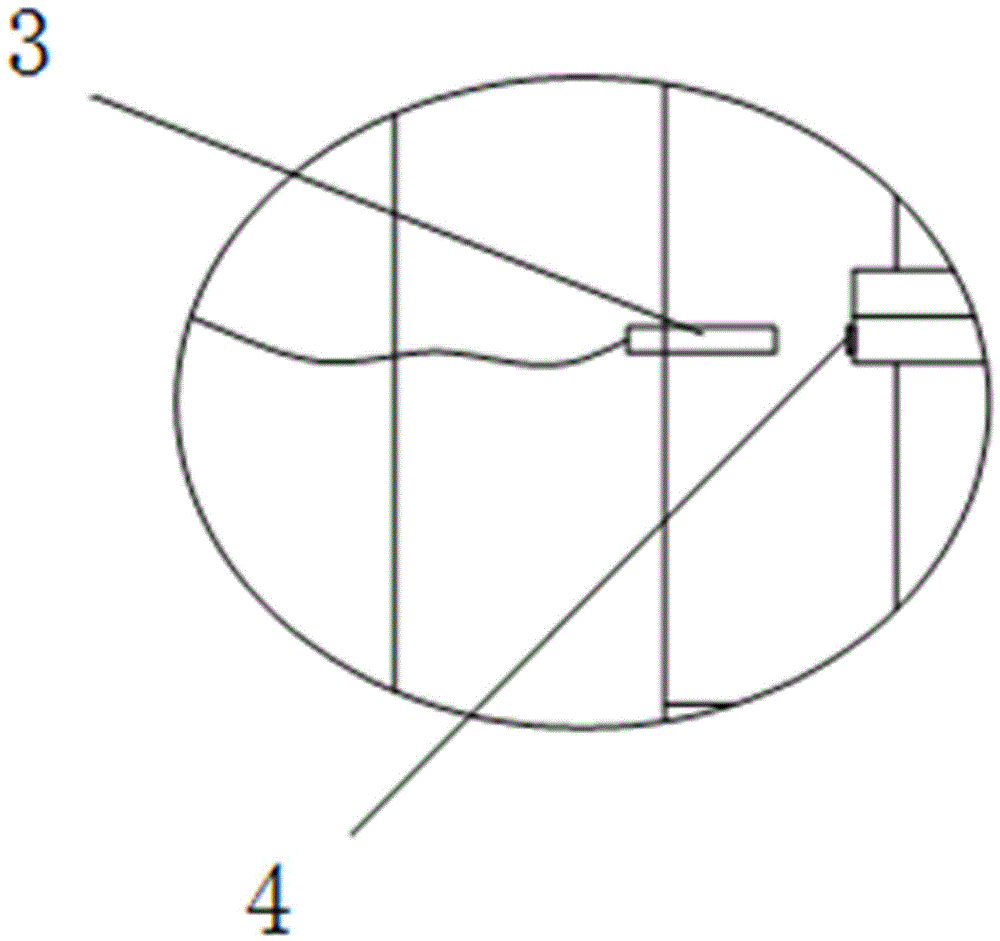

[0029] Such as Figure 1~4 As shown, an urban drainage axial flow pump maintenance test run control device. The axial flow pump includes a vertically arranged electric motor 12, and an impeller 6 connected to the shaft of the electric motor 12 through a water-stop packing pressure plate 5. The control device includes: The pumping end of the wall pipe 11 is immersed in water, and the water outlet end passes through the wall and is located outside the wall. The impeller 6 is located at the pumping end of the wall pipe 11, and the water outlet end of the wall pipe is provided with a water outlet flap door 10 ; The temperature sensor 2, which is set on the motor 12, is used to detect the temperature of the motor and output temperature signals; the speed sensor 3, which is used to detect the rotation speed of the motor shaft an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap