Hydraulic synchronous control device for fan-shaped section replacement device

A hydraulic synchronization and control device technology, which is applied in the direction of fluid pressure actuators, servo motors, servo meter circuits, etc., to achieve the effects of achieving stability, improving synchronization accuracy, achieving safety stability and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

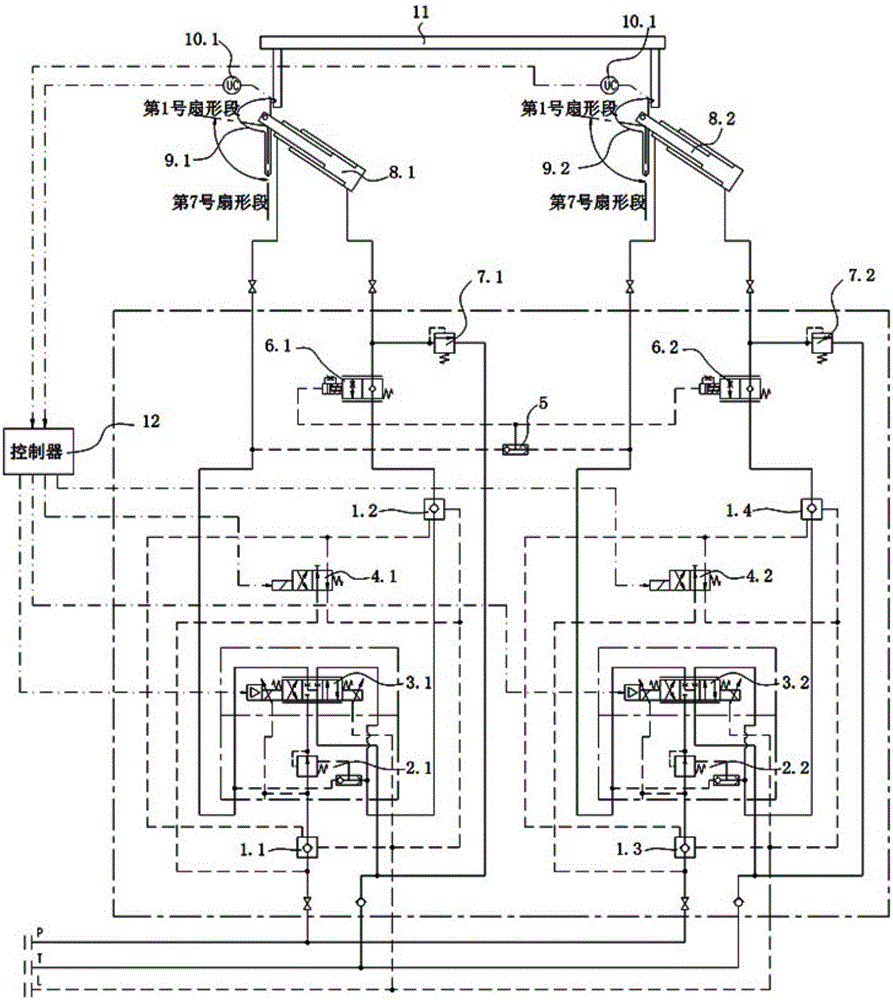

[0021] A hydraulic synchronous control device for a sector replacement device, comprising an actuator of the sector replacement device, a controller 12 and a hydraulic synchronous control circuit of a dual proportional valve, the hydraulic synchronous control device controls the hydraulic synchronous control circuit of the dual proportional valve through the controller 12 Closed-loop control is carried out to realize the synchronous movement of the actuator of the segment replacement device.

[0022] The actuator of the sector replacement device is composed of swing hydraulic cylinders 8.1, 8.2, guide swing arms 9.1, 9.2 and lifting beam 11, the output ends of swing hydraulic cylinders 8.1, 8.2 are connected to one end of guide swing arms 9.1, 9.2, and the guide swing The other end of the arms 9.1, 9.2 is connected to the lifting beam 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com