A hydraulic reversing circuit without channeling and its reversing method

A hydraulic and cross-flow technology, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, servo meter circuits, etc., can solve the problems of ineffective control of oil pollution and shuttle valve cross-flow, etc., to improve work efficiency Reliability, reduced equipment failure rate, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

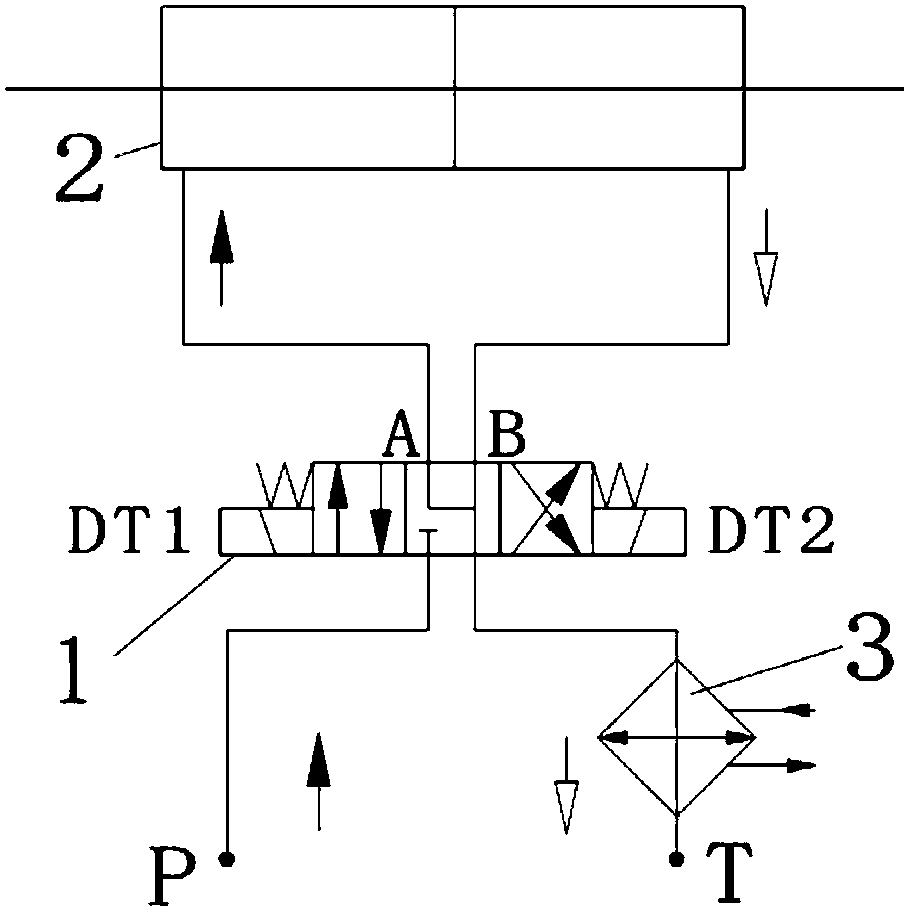

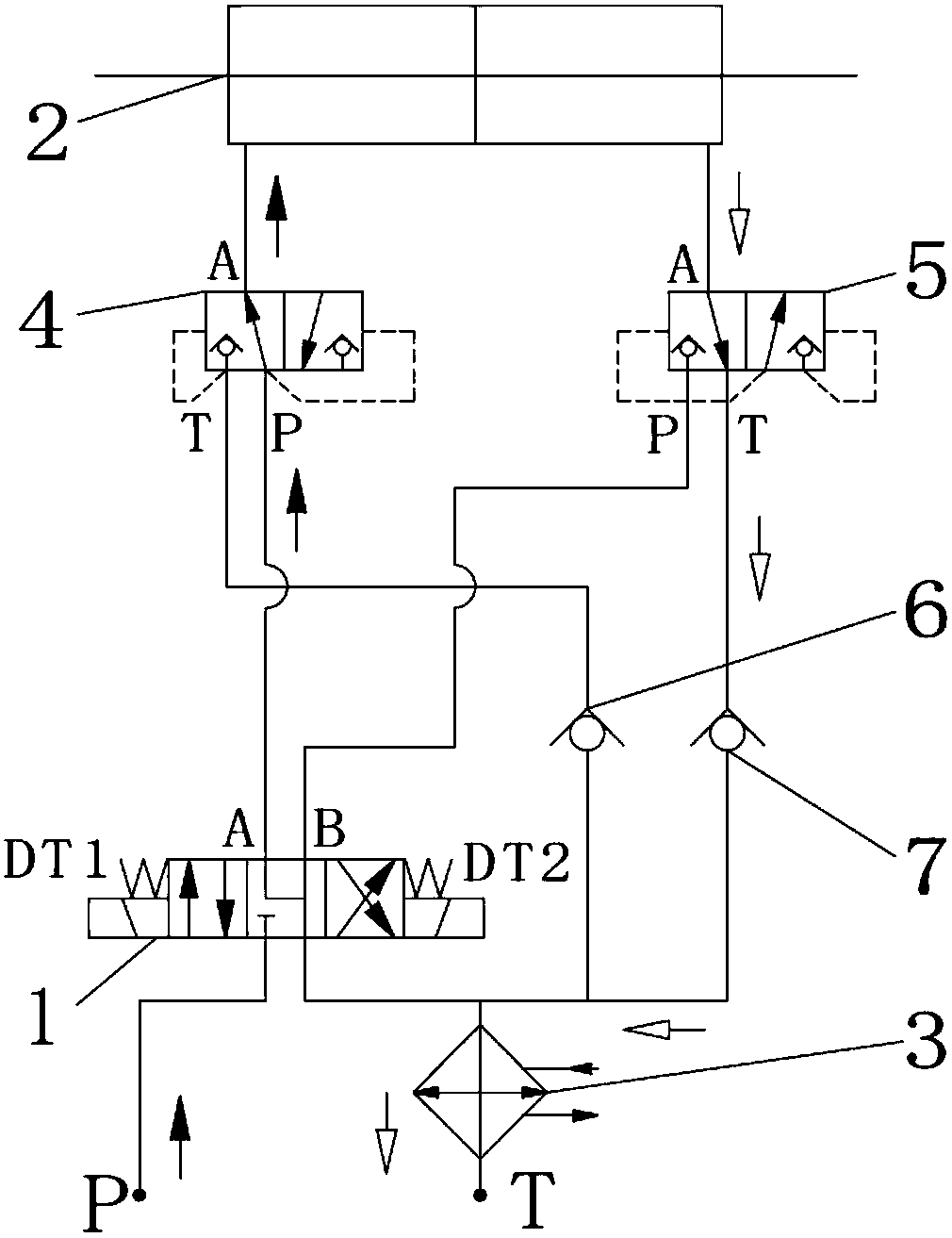

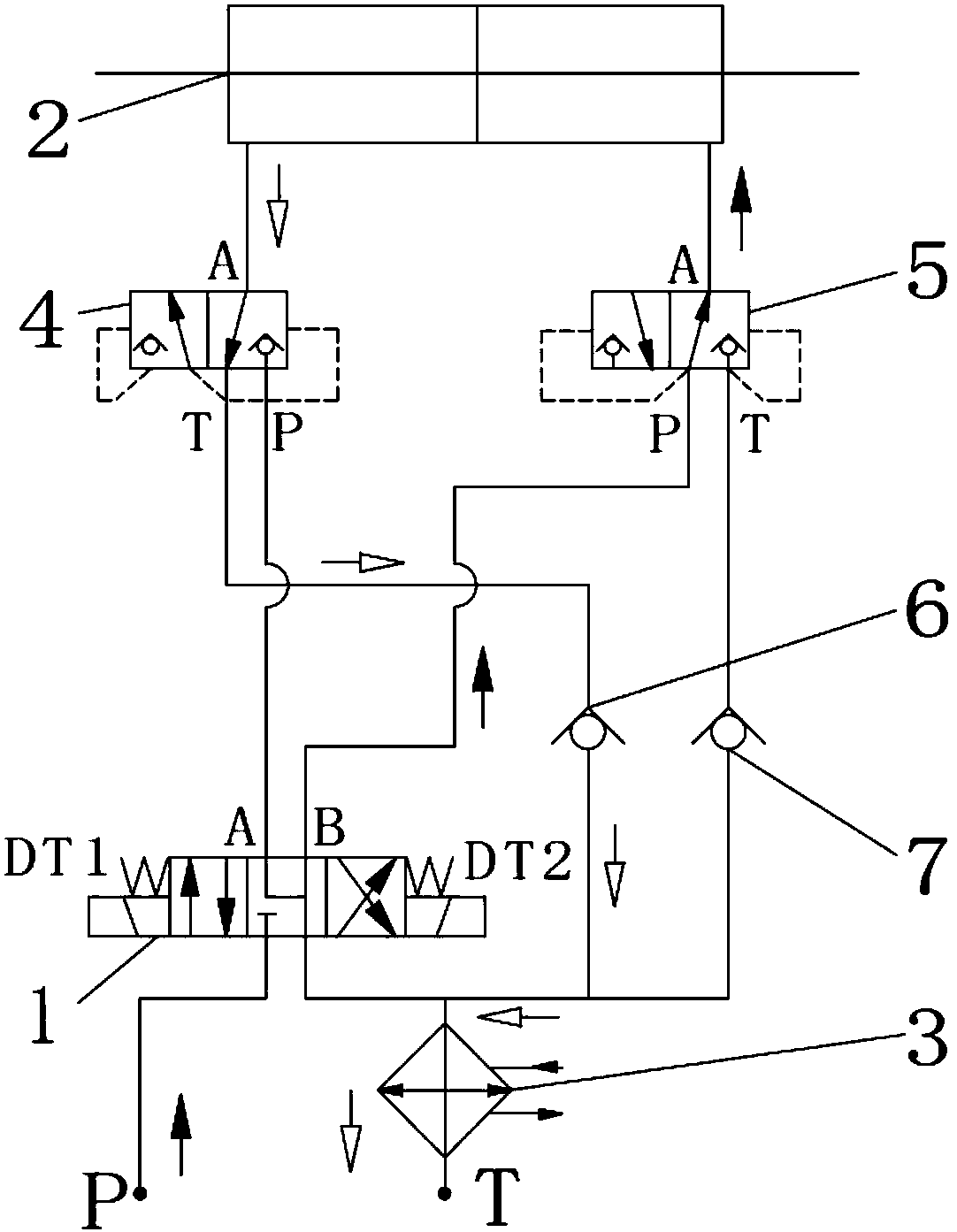

[0038] A hydraulic reversing circuit without channeling. The reversing circuit does not change the original function of the reversing circuit. It creatively cooperates with a new type of shuttle valve and arranges it in combination, so that the hydraulic reversing circuit realizes that the circuit independently passes through the oil tank. Effect. In this embodiment, the shuttle valve disclosed in "A New Structural Design of Shuttle Valve" disclosed in the fourth issue of "Hydraulic and Pneumatic" in 2009 is preferably used.

[0039] The principle of the hydraulic reversing circuit see figure 2 , image 3 As shown, it consists of a reversing valve 1, a hydraulic cylinder 2, a first shuttle va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com