Flange sealing and installing structure of washing machine inner cylinder bottom

A flange sealing and installation structure technology, applied in the field of washing machines, can solve problems such as affecting the sealing effect, inability to effectively prevent, etc., achieving the effects of convenient installation, saving washing costs, and avoiding cross infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

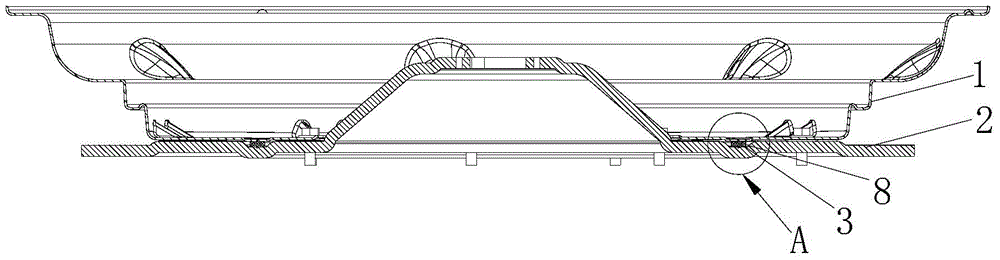

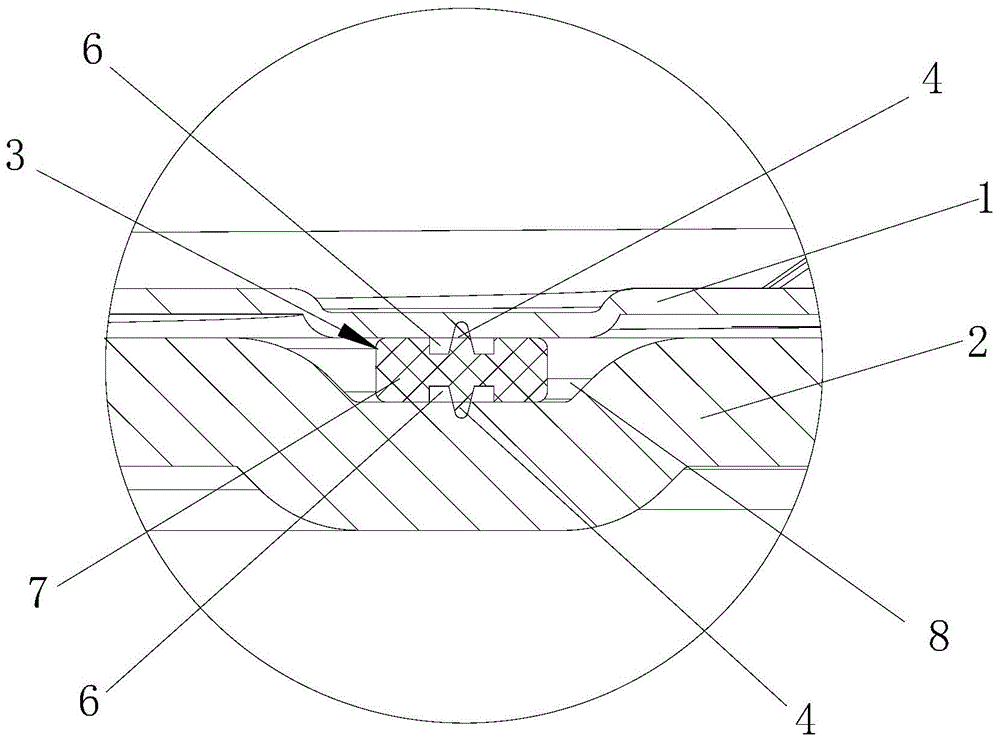

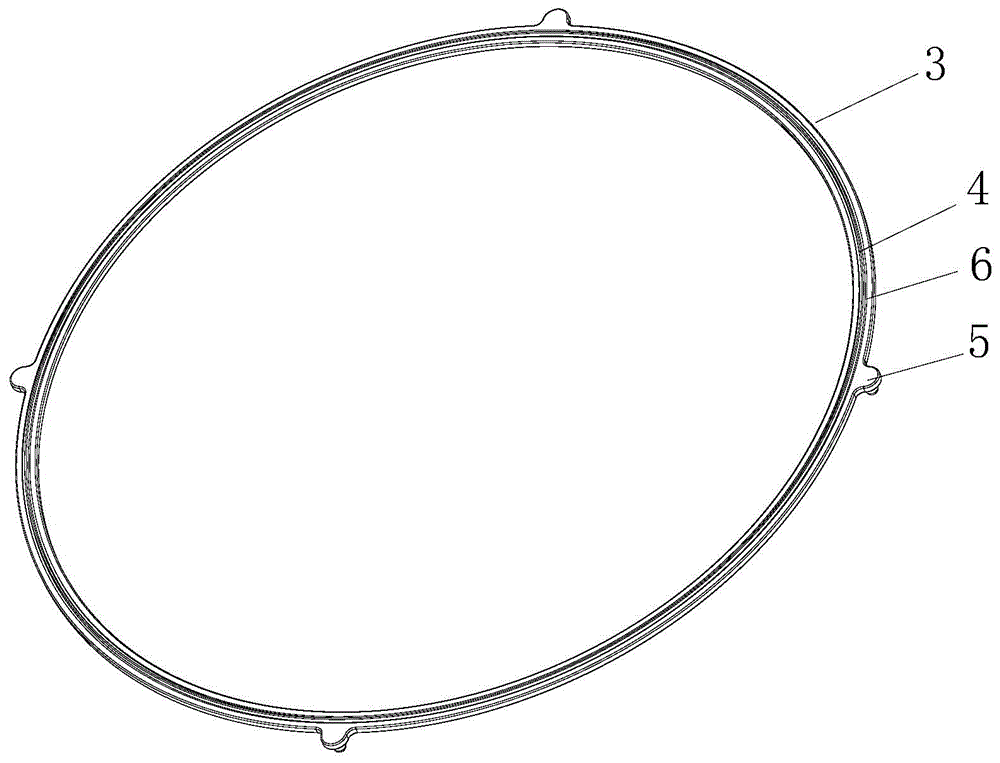

[0034] like figure 2 , image 3 As shown, the sealing ring 3 of the present invention is a flat annular structure, and an annular sealing rib 4 is provided on the upper surface and / or the lower surface of the sealing ring 3 . Due to the large radius of the sealing ring installed at this position, the ordinary sealing ring is easily displaced or rolled up and deformed by force during installation, and the sealing effect cannot be achieved. The above-mentioned flat ring structure of the present invention increases the stability of the sealing ring during installation , to avoid deformation and displacement, and at the same time use the annular sealing rib on the surface to effectively achieve the sealing effect.

Embodiment 2

[0036] like Figure 5 , Image 6 As shown, the upper surface and / or the lower surface of the sealing ring 3 are respectively provided with two annular sealing ribs 4 .

Embodiment 3

[0038] like image 3 As shown, the sealing ring 3 and the flange 2 in this embodiment are provided with a matching positioning structure.

[0039] The positioning structure includes a positioning protrusion 5 provided on the sealing ring 3 and a positioning groove (not shown) provided on the flange 2 to match the positioning protrusion.

[0040] More preferably, the positioning protrusion 5 integrally protrudes from the outer periphery of the sealing ring 3 , and the notch integrally formed on the outer periphery of the limiting sinker 8 constitutes the positioning groove.

[0041] The positioning structure can ensure that the sealing ring 3 does not shift radially and along the circumference when the sealing ring 3 is squeezed by the inner tub bottom 1 and the flange 2 and is subjected to a torque force when the washing machine is working. Ensure the sealing effect of the sealing ring 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com