Electric arc furnace

A technology of electric arc furnace and furnace body, applied in the field of electric arc furnace, can solve the problems of poor temperature control effect of furnace cover, high temperature control difficulty, poor cooling effect, etc., and achieves stable structure, reduced manufacturing cost and high support strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

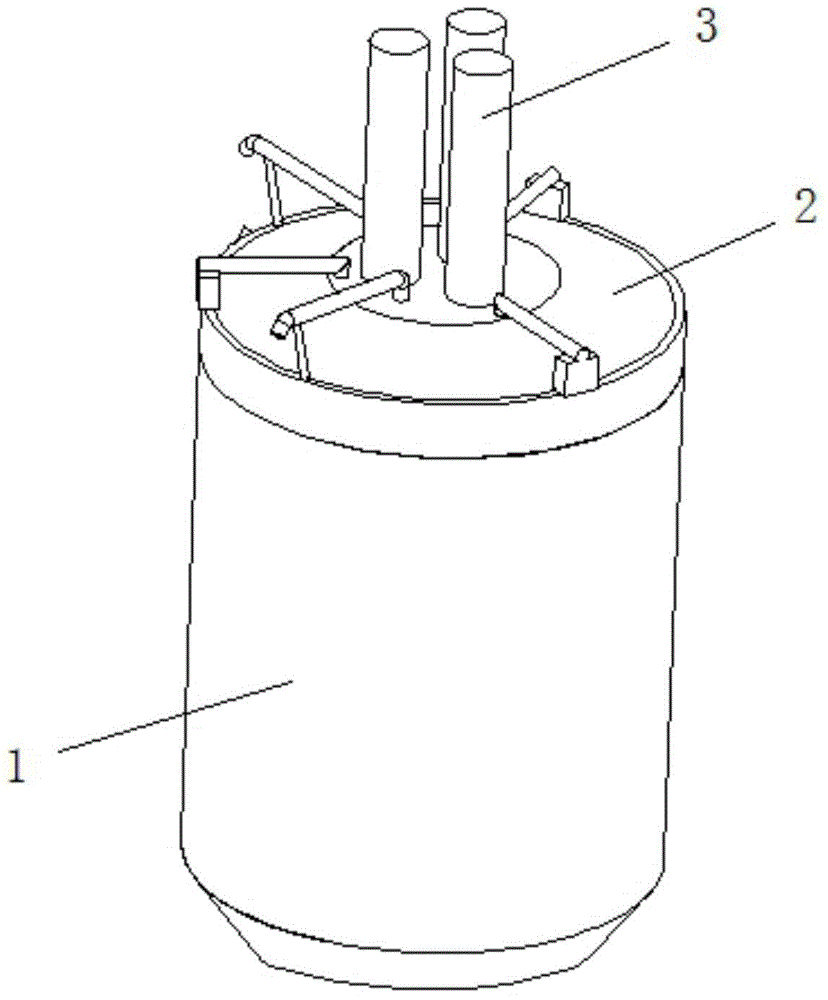

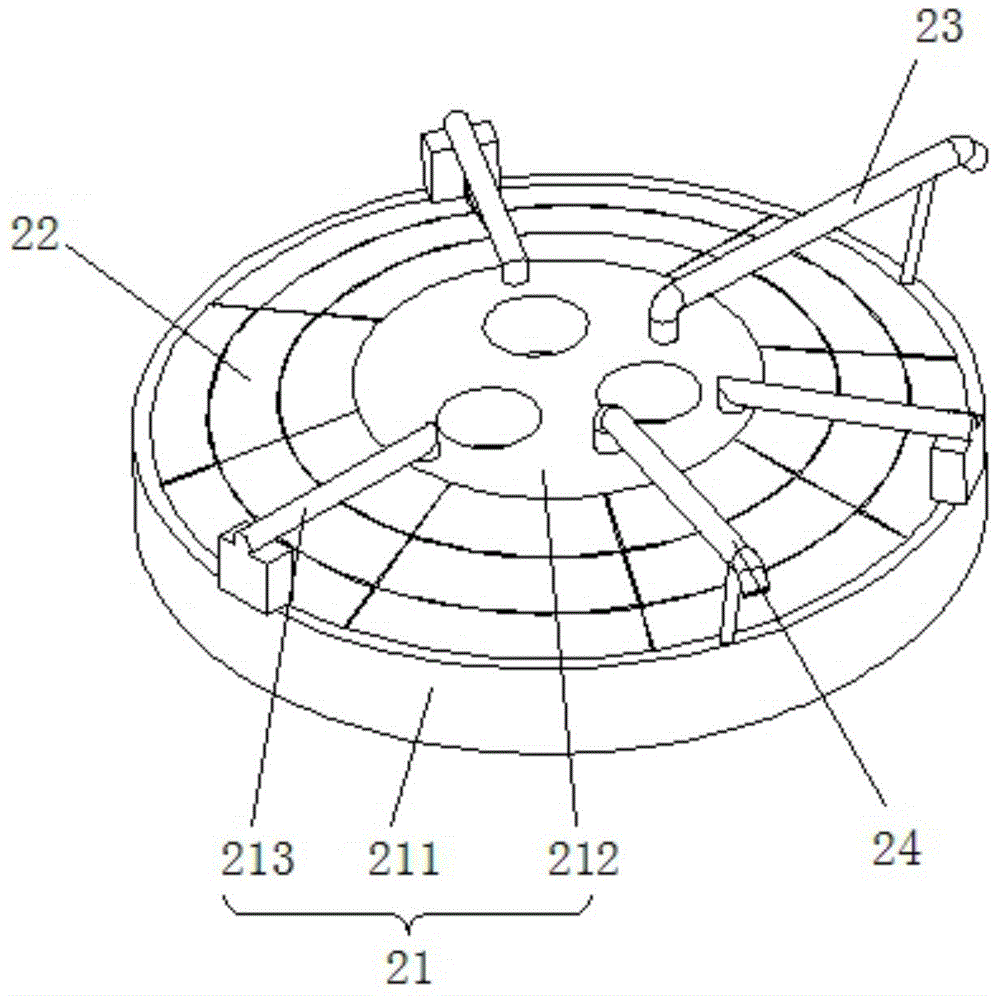

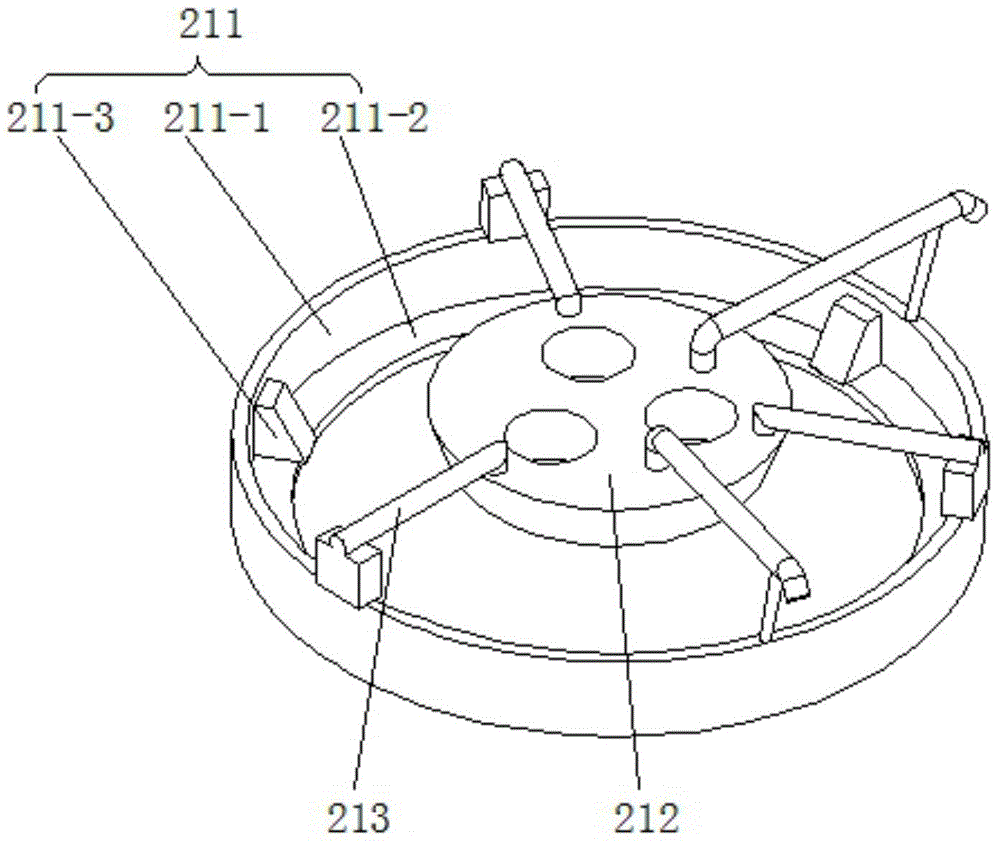

[0021] See Figure 1 to Figure 4 , the present invention has a furnace body 1, a furnace cover 2 and an electrode 3; the furnace cover 2 is set on the mouth of the furnace body 1, and the electrode 3 extends into the furnace body 1 from the furnace cover 2; One side is provided with a feed port, and the other side of the furnace body 1 is provided with a slag outlet and a discharge port; the furnace cover 2 includes a support frame 21 and a refractory cover body 22; the support frame 21 includes a bottom ring 211, a top Cover 212 and connecting beam 213; the interior of the top cover 212 is hollow; the furnace cover 2 is fixedly provided with a water inlet pipe 23 and an outlet pipe 24 that are connected to the interior of the top cover 212; the bottom ring 211 surrounds Outside the top cover 212 and coaxial with the top cover 212, the upper end surface of the top cover 212 is higher than the upper end surface of the bottom ring 211; the top cover 212 is in the shape of a trun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com