A mold and test block manufacturing method capable of accurately fixing joint shear test specimens

A shear test and mold technology, applied in the field of rock mass mechanical performance test, can solve the problems of difficult to ensure the accurate occlusion of the joint surface of the test piece, the depth of the test piece buried in the mortar cannot be guaranteed, and the joint surface occlusion is not tight enough, etc. Fast and convenient, ensure reliability, avoid blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

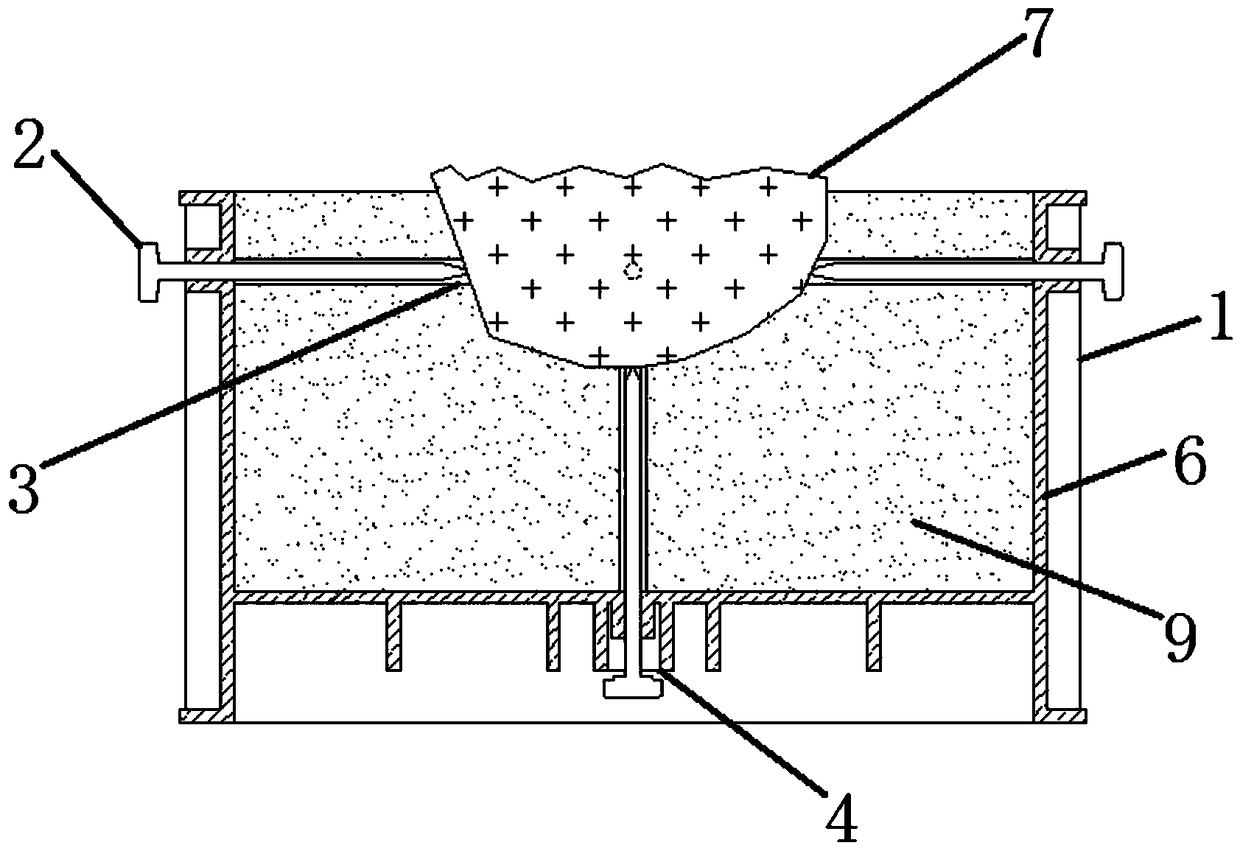

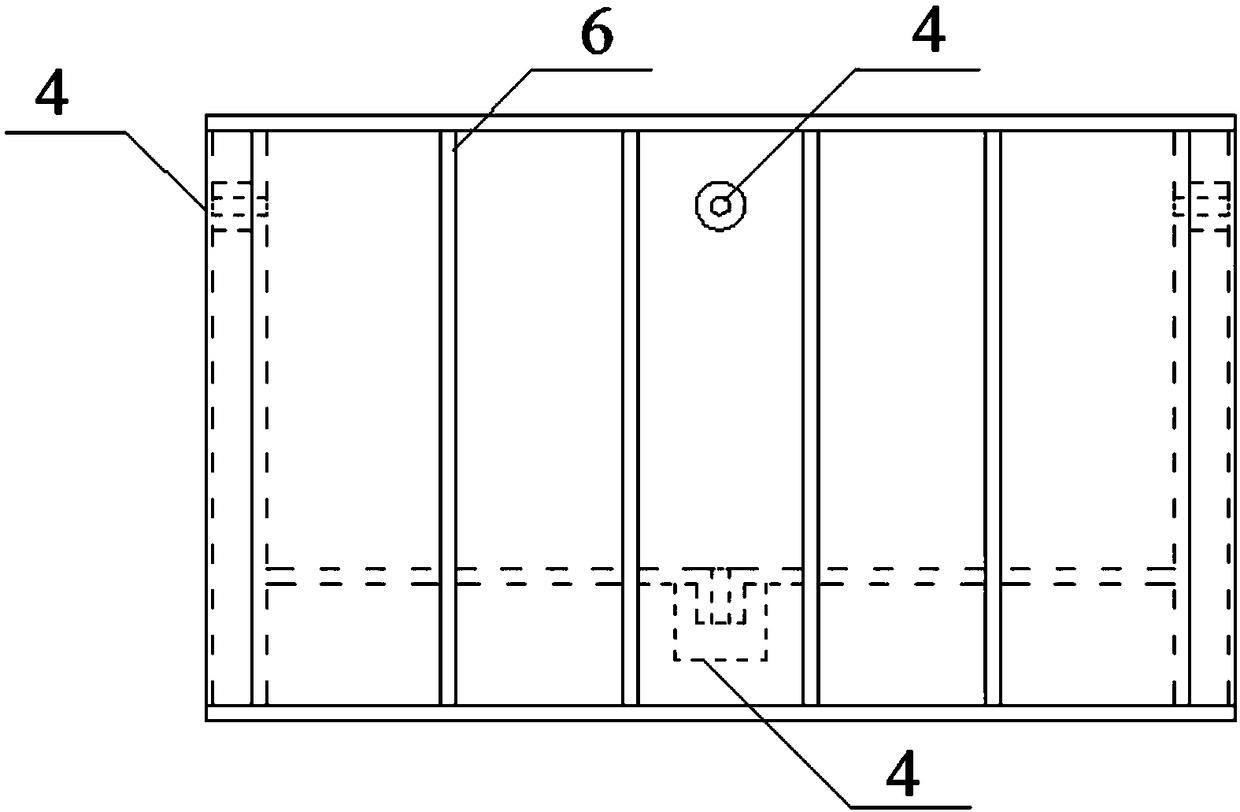

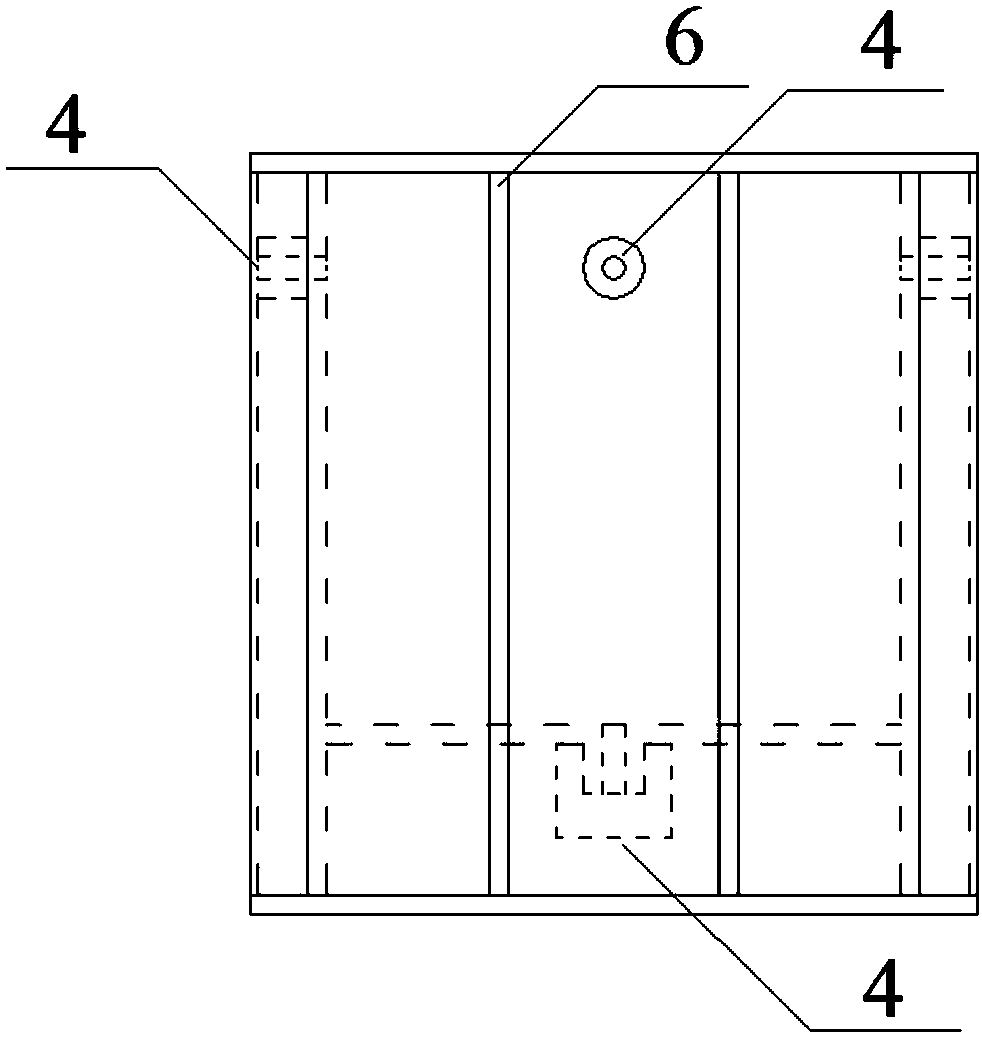

[0043] Such as Figure 1-4 Shown is a mold that can accurately fix joint shear test specimens. The mold includes a mold body 1 with an open upper end. Limit bolt holes 4 are provided on the side and bottom surfaces of the mold body 1. Inside the limit bolt holes 4 are The limit bolt 2, the structure of the limit bolt 2 is as follows Figure 5 Shown in (a).

[0044] Wherein, the mold main body 1 is a rectangular mold main body with an upper end opening, and limit bolt holes 4 are provided on the four sides and the bottom surface of the rectangular mold main body. The limit bolt hole 4 on the side of the mold main body 1 is located on the vertical central axis of the corresponding side, and the distance from the top of the side is 30mm. The limit bolt hole 4 on the bottom surface of the mold main body 1 is located at the center of the bottom surface.

[0045] The length of the threaded section of the limit bolt 2 is 50mm. The outer sleeve of the limit bolt 2 is provided with...

Embodiment 2

[0058] In this embodiment, the limit bolt hole 4 on the side of the mold main body 1 is located on the vertical central axis of the corresponding side, and the distance from the top of the side is 20mm, the length of the threaded section of the limit bolt 2 is 30mm, and the rest are the same as in the embodiment 1.

Embodiment 3

[0060] In this embodiment, the limit bolt hole 4 on the side of the mold main body 1 is located on the vertical central axis of the corresponding side, and the distance from the top of the side is 40mm, the length of the threaded section of the limit bolt 2 is 40mm, and the rest are the same as in the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com