Method for making complete dentures with individualized polished surfaces using old dentures

A technology for complete dentures and polished surfaces, applied in the field of complete dentures, can solve the problems of mucosal irritation, laborious accuracy, poor fluidity of self-setting resin, etc. The effect of avoiding mucosal irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 1-9 As shown, the present embodiment provides a method for utilizing old dentures to make complete dentures with personalized polished surfaces, including the following specific steps:

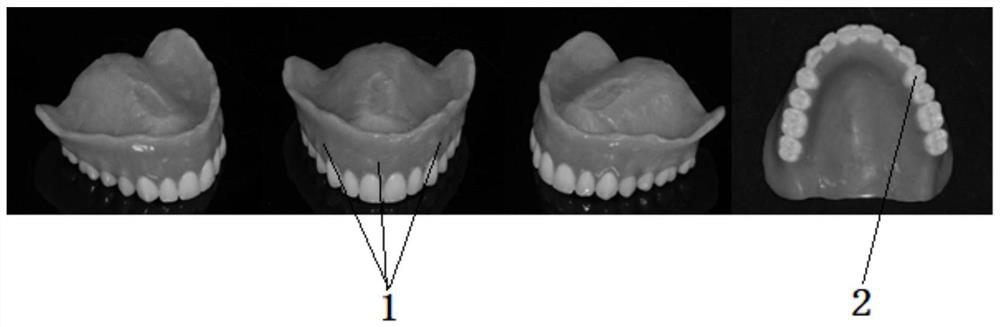

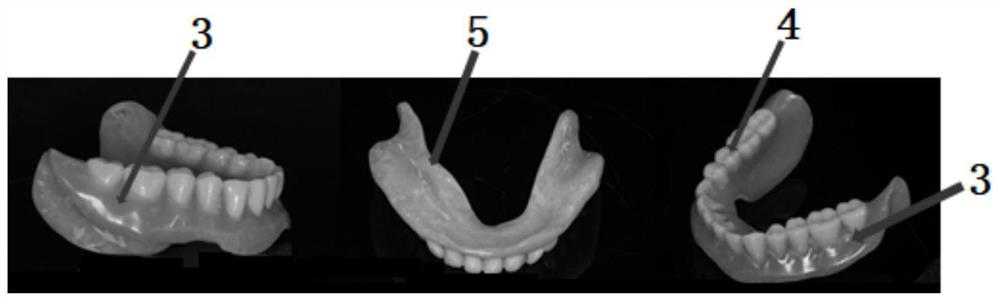

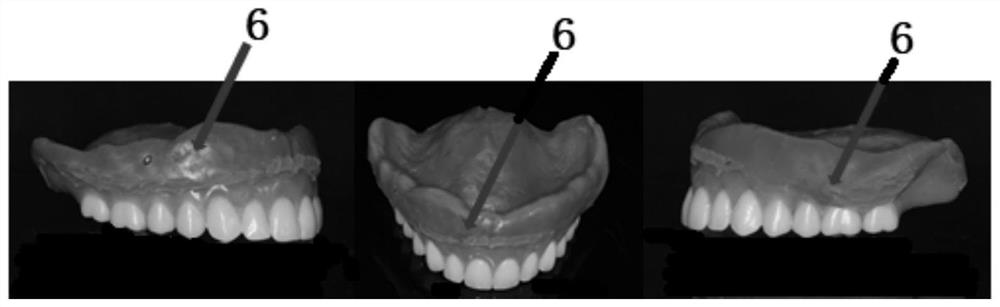

[0036] Prepare the old maxillary denture and old mandibular denture provided by the patient. The occlusion of the old maxillary denture and the old mandibular denture are relatively stable and the jaw position is correct, and the extension of the denture edge is basically in place; figure 1 and figure 2 As shown, among them, figure 1 The reference sign 1 in the figure refers to the polished surface form of the old maxillary denture, and the reference sign 2 refers to the dentition of the old maxillary denture. It can be seen that the polished surface form is artificially made, not a personalized form. The dentition Mild abrasion; where, figure 2 Reference numeral 3 in the figure refers to the polished surface of the old mandibular denture, reference numeral 4 refers to...

Embodiment 2

[0046] This embodiment is a further improvement made on the basis of Embodiment 1, and the specific differences between this embodiment and Embodiment 1 are:

[0047] It should be further explained in this example that, before the final impression is made, if the edges of the old maxillary denture and the old mandibular denture are short, edge shaping is performed to lengthen the short margin, such as the lingual flange in this example. Avoid the lingual flange area of the old mandibular denture is too short, thereby destroying the retention effect of the patient's new complete denture.

[0048] The present invention is aimed at patients with poor alveolar ridge conditions and who have made complete dentures in traditional ways, which may not achieve the ideal restoration effect, and the retention and stability may not meet the needs of patients. The retention and stability of the denture can be improved by making the patient's personalized polished surface to increase the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com