Method for manufacturing complete implant dental bridge

A manufacturing method and dental implant technology, applied in the field of oral cavity, can solve problems such as increased labor costs and material costs, poor occlusion, inaccurate occlusal records, etc., to achieve material and labor cost control, accurate occlusion and placement, and improve satisfaction degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

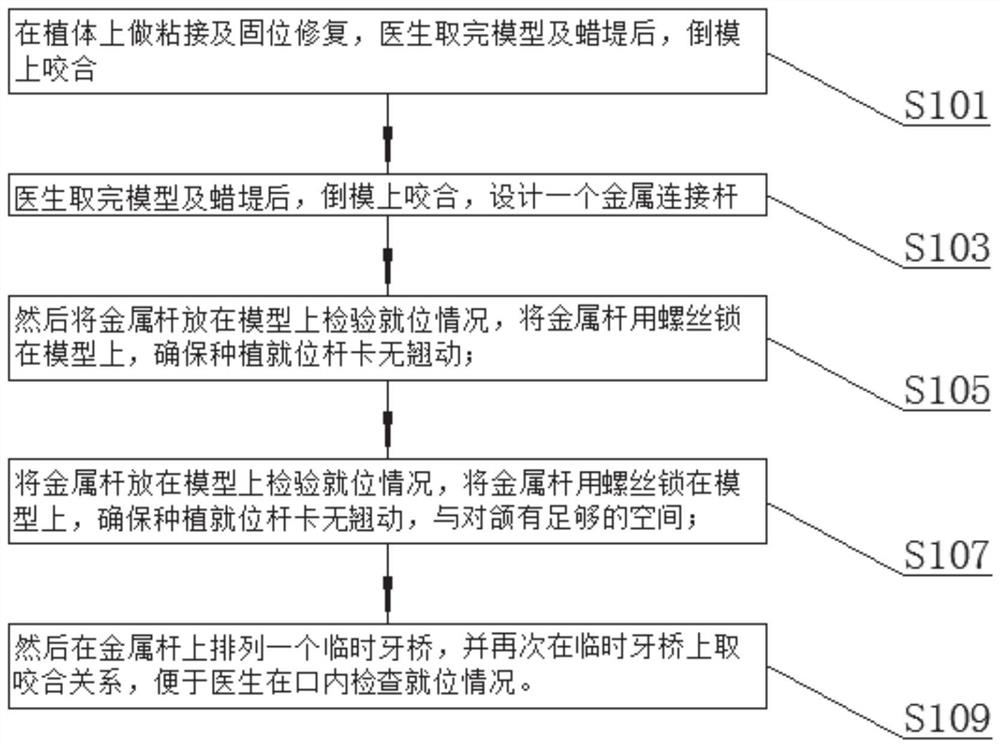

[0032] like Figure 1-6 As shown, the method for making a full-mouth implant bridge according to an embodiment of the present invention includes the following steps;

[0033] Do bonding and retention repair on the implant, after the doctor has taken the model and wax embankment, the mold will be occluded;

[0034] After the doctor took the model and the wax embankment, he reversed the model and occluded it, and designed a metal connecting rod;

[0035] Then put the metal rod on the model to check the in-position situation, and lock the metal rod on the model with screws to ensure that the planting in place bar card does not warp;

[0036] Put the metal rod on the model to check the in-position situation, and lock the metal rod on the model with screws to ensure that the implant is in place without warping and there is enough space with the opposing jaw;

[0037] Then arrange a temporary bridge on the metal rod, and take the occlusal relationship on the temporary bridge again...

Embodiment 2

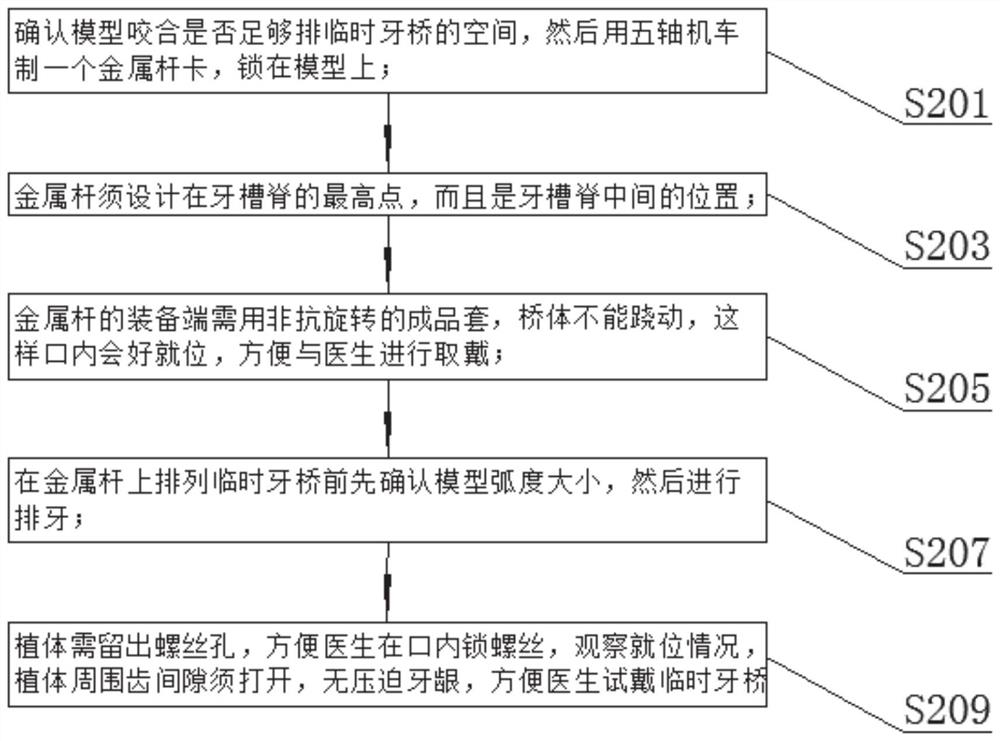

[0039] like Figure 1-6 As shown, before making the metal rod, the following steps are also included;

[0040] Confirm whether the occlusion of the model is enough to accommodate the temporary bridge, and then use a five-axis locomotive to make a metal bar and lock it on the model;

[0041] The metal rod must be designed at the highest point of the alveolar ridge and in the middle of the alveolar ridge;

[0042] The equipment end of the metal rod needs to use a non-rotation-resistant finished sleeve, and the bridge body cannot be tilted, so that the mouth will be in place, and it is convenient to take and wear with the doctor;

[0043] Before arranging the temporary bridge on the metal rod, first confirm the radian size of the model, and then arrange the teeth;

[0044] Screw holes should be reserved for the implant, so that the doctor can lock the screw in the mouth and observe the position. The gap between the teeth around the implant must be opened so that there is no pre...

Embodiment 3

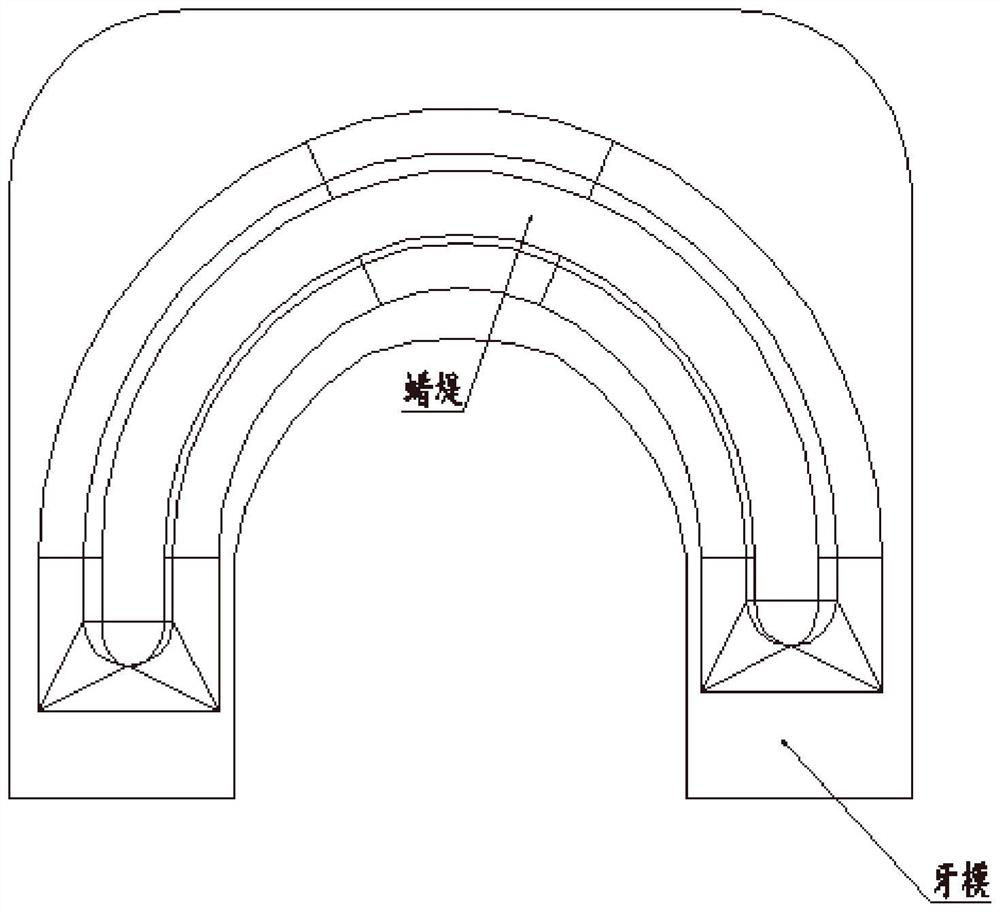

[0046] like Figure 1-6 As shown, the metal bar is 3mm high, 2mm wide and 2-3mm space is reserved for the gums. The upper jaw of the row of teeth usually has (T1, T3, T6, TL1), and the lower jaw has (5L, 8L). The size of the row of teeth is arranged, and the occlusal relationship is taken on the temporary dental bridge, and the occlusal, length, radian, size and length in the mouth can be checked on the temporary dental bridge.

[0047] like figure 1 As shown, according to the embodiment of the present invention, a method for making a full-mouth implant bridge is also provided.

[0048] Include the following steps:

[0049] S101. Perform bonding and retention repair on the implant. After the doctor takes the model and wax embankment, the model is reversed and occluded;

[0050] S103. After the doctor takes the model and the wax embankment, he inverts the model and occludes it, and designs a metal connecting rod;

[0051] S105, then put the metal rod on the model to check t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com