Double-roller oblique-rolled steel tube oblique defect magnetic leakage detection method and detection device

A technology for magnetic flux leakage detection and steel pipe rolling, applied in the direction of material magnetic variables, etc., can solve the problems of magnetic leakage detection of oblique defects in steel pipes, and achieve the effect of highlighting substantive characteristics and improving detection capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

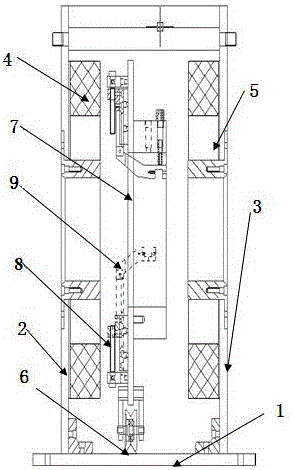

[0024] Example 1, see figure 1 According to the design requirements, it is processed into the installation base plate 1, the front support plate (installation side plate) 2, the rear support plate (installation side plate) 3, the oblique magnetization coil 4, the oblique magnetization circuit device 5, the fixed guide rail 6, the oblique To the detection plate 7, probe support and adjustment device 8, oblique probe 9; fix the front support plate (installation side plate) 2, rear support plate (installation side plate) 3 on the front and rear sides of the installation base plate 1 respectively, and fix the The guide rail 6 is installed in the middle of the installation base plate 1, the oblique magnetization coil 4 is installed on the inner side of the front support plate (installation side plate) 2, and the oblique magnetization circuit device 5 is installed on the inner side of the rear support plate (installation side plate) 3; There is a round hole in the middle of the dete...

Embodiment 2

[0025] Embodiment 2, using the device of the above embodiment to realize the magnetic flux leakage detection method for oblique defects of two-roll cross-rolled steel pipes, including the following process steps:

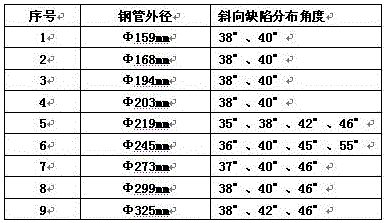

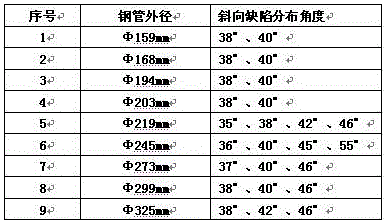

[0026] a Find out the angle distribution law of the oblique defects of the steel pipes produced by the two-roll cross-rolling process; through the statistics of the angle distribution of the oblique defects of the steel pipes of different specifications, the results show that the steel pipes produced by the two-roll cross-rolling process are The process characteristics of the oblique defects are related to the outer diameter of the steel pipe. The oblique defects of the steel pipes with four outer diameter specifications of Φ159mm, Φ168mm, Φ194mm, and Φ203mm are distributed at two angles; the oblique defects of the steel pipes with two outer diameter specifications of Φ219mm and Φ245mm The defects are distributed in 4 angles; the oblique defects of steel pipes with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com