A three-dimensional measurement system and method for large-space steady-state flow field

A steady-state flow field, three-dimensional measurement technology, applied in the direction of fluid velocity measurement, full-field flow measurement, measurement device, etc. Improve the maximum measurable direction angle range and accuracy, fast real-time positioning measurement, and reduce the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

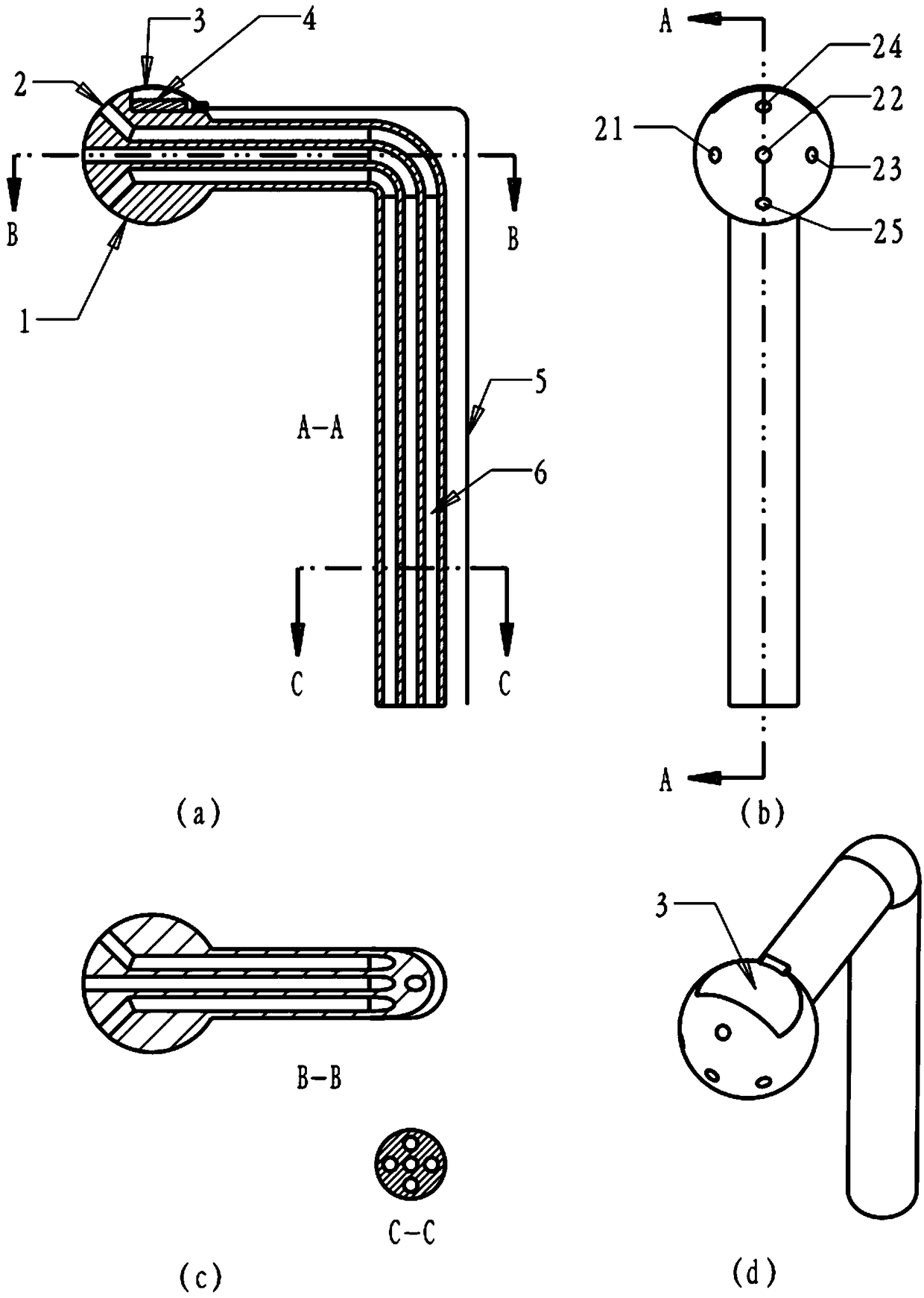

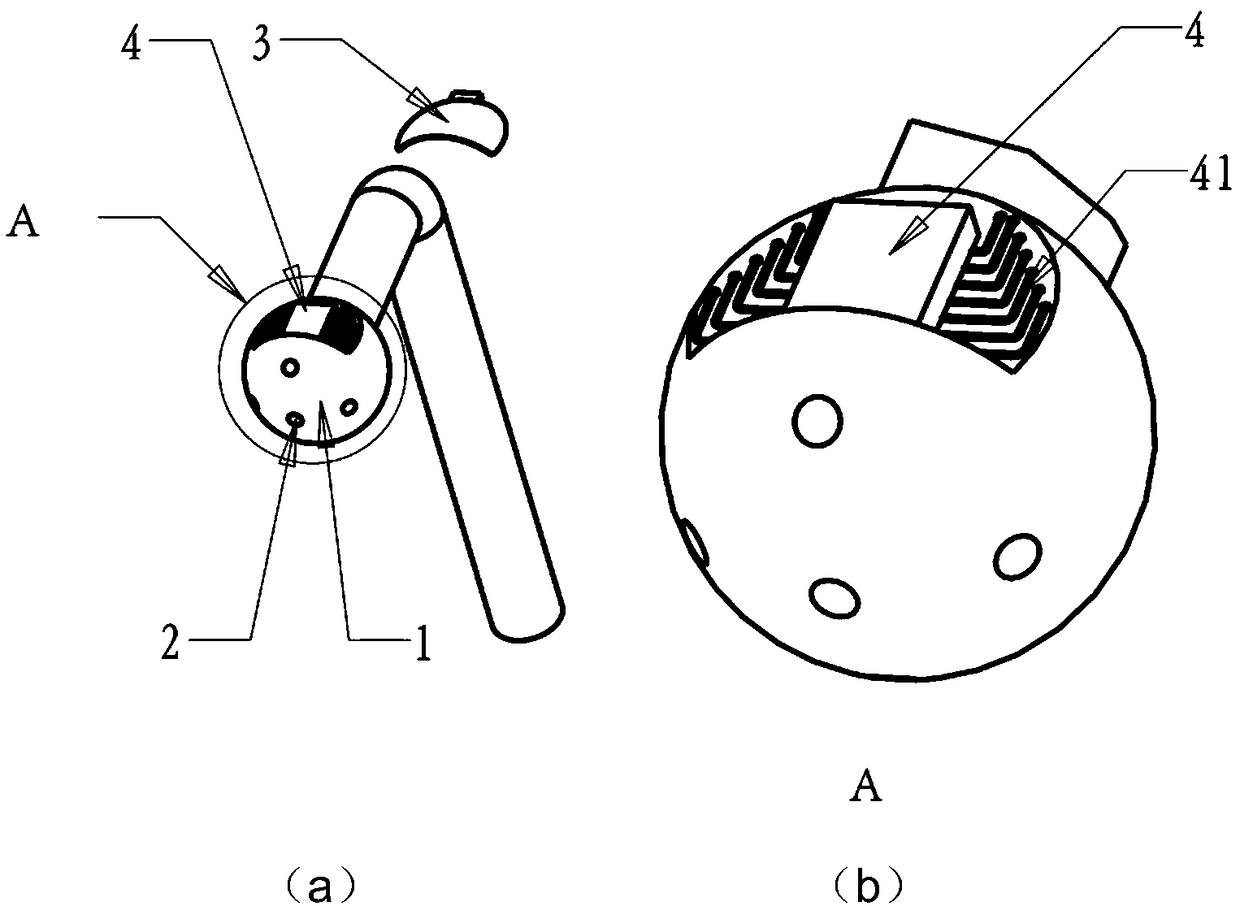

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

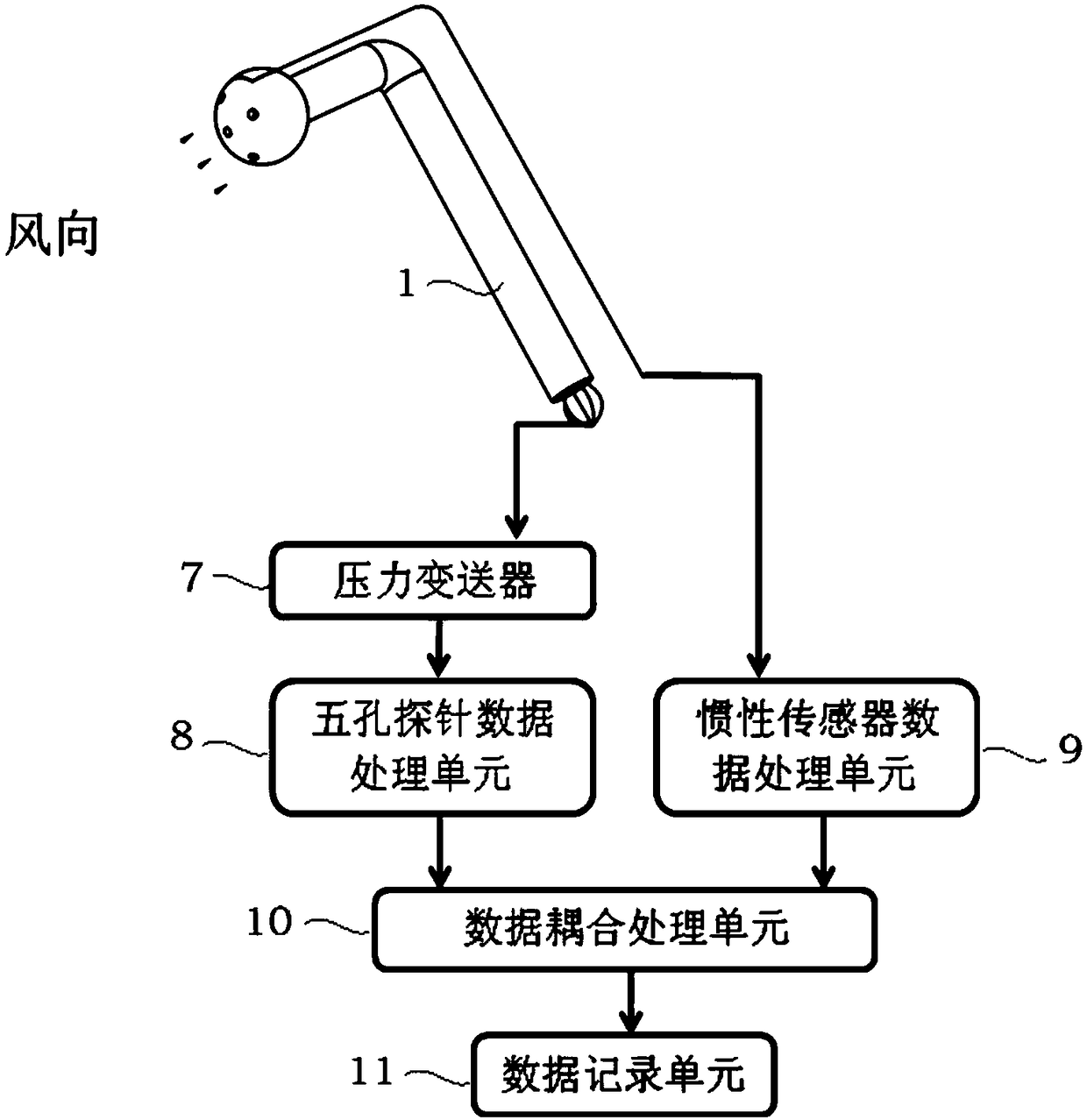

[0043] see figure 1 As shown, the present invention is a three-dimensional measurement system for a large-space steady-state flow field, including a five-hole probe 1 with a built-in inertial sensor 4, which is used to measure the velocity vector of a single point in the steady-state flow field.

[0044] The pressure transmitter is used to collect and transmit the information of the five pressure measuring points of the five-hole probe conveyed through the pressure measuring pipeline;

[0045] The five-hole probe data processing unit uses the built-in five-hole probe calibration characteristic curve to process the information of the five pressure measuring points of the pressure transmitter to obtain the velocity vector of the measured coordinate point;

[0046] The inertial sensor is used to measure the relative linear acceleration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com