Method for allocating tasks to operator and device thereof

A technology for allocating tasks and operators, applied in the field of warehouse management, can solve the problems of difficult configuration parameters, reduced operation efficiency, difficult to use, etc., to achieve the effect of improving execution efficiency, meeting the requirements of task time, and rationally arranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

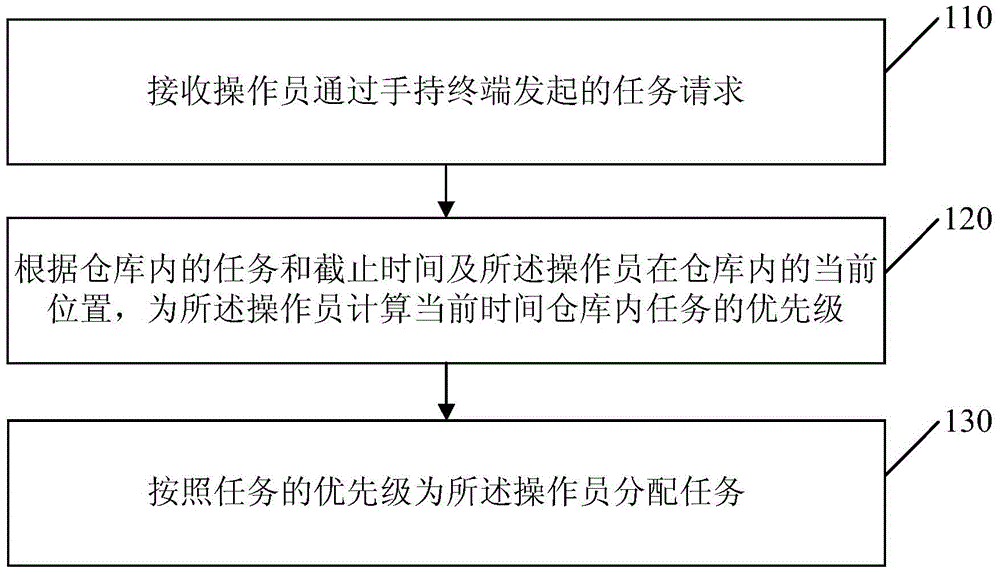

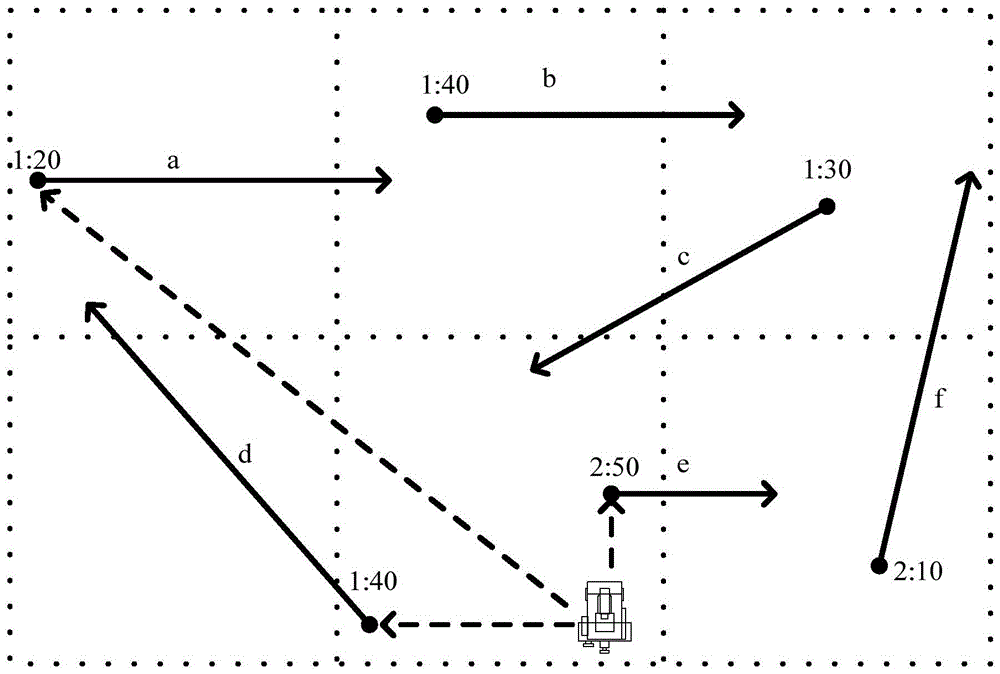

[0044] figure 1 It is a flowchart of the method for assigning tasks to operators provided in the first embodiment of the present invention. This embodiment is suitable for assigning reasonable tasks to operators according to the tasks in the warehouse. The method can be executed by WMS and specifically includes the following steps :

[0045] Step 110: Receive a task request initiated by an operator through a handheld terminal.

[0046] When the operator is not performing a task, he can initiate a task request through the equipped handheld terminal. After the handheld terminal receives the task request initiated by the operator, the task request is sent to the WMS, and the WMS can receive the operator A task request is initiated to assign tasks to the operator according to the task request.

[0047] Step 120: Calculate the priority of the tasks in the warehouse at the current time for the operator according to the tasks and deadlines in the warehouse and the current position of the o...

Embodiment 2

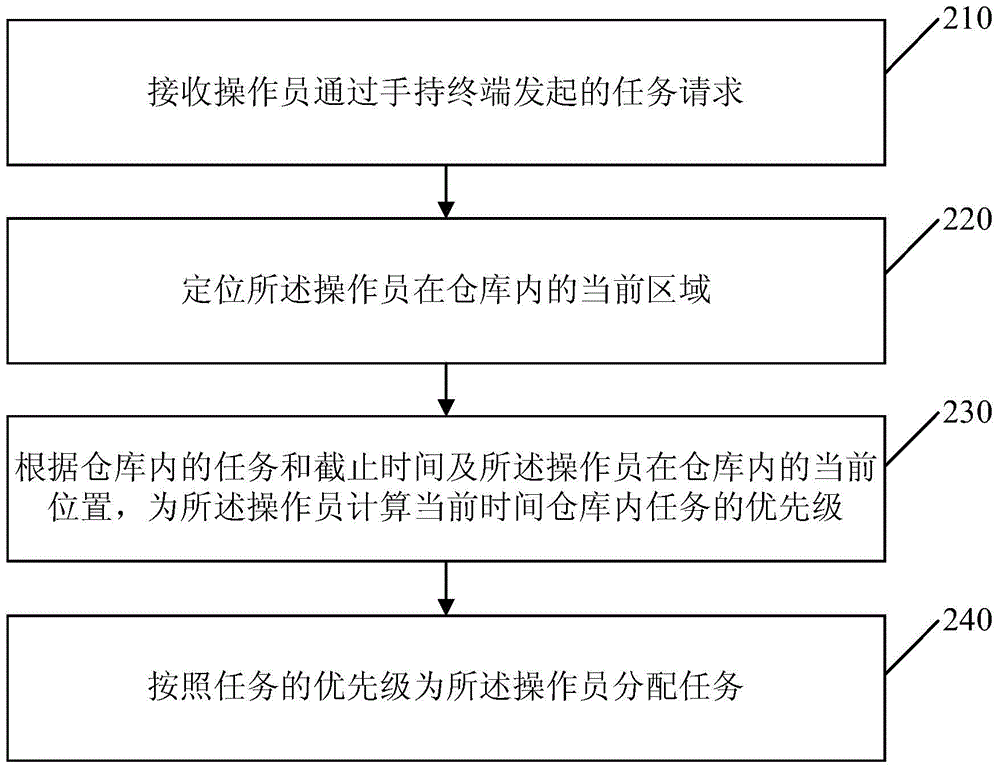

[0057] figure 2 It is a flowchart of the method for assigning tasks to operators provided in the second embodiment of the present invention, which specifically includes the following steps:

[0058] Step 210: Receive a task request initiated by an operator through a handheld terminal.

[0059] Step 220: Locate the current area of the operator in the warehouse.

[0060] The warehouse is divided into at least two areas, and the area division of the warehouse is performed before receiving the task request initiated by the operator through the handheld terminal.

[0061] The operator can scan the barcode representing the area number through the handheld terminal and send the scan result to the WMS, so that the WMS can locate the operator’s current area in the warehouse; it can also take pictures of the operator and its location through the camera. Image recognition locates the operator's current area in the warehouse; other methods can also be used to locate the operator's current area...

Embodiment 3

[0074] Figure 4 It is a flowchart of the device for assigning tasks to operators provided in the third embodiment of the present invention, such as Figure 4 As shown, the device for assigning tasks to operators provided in this embodiment includes: a task request receiving module 410, a task priority calculation module 420, and a task scheduling module 430.

[0075] Wherein, the task request receiving module 410 is used to receive the task request initiated by the operator through the handheld terminal;

[0076] The task priority calculation module 420 is configured to calculate the priority of the tasks in the warehouse at the current time for the operator according to the tasks and deadlines in the warehouse and the current position of the operator in the warehouse;

[0077] The task scheduling module 430 is configured to allocate tasks to the operator according to the priority of the task.

[0078] Preferably, it also includes:

[0079] The login module is used for receiving and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com