Continuous adjustable millimeter wave waveguide attenuator

A waveguide attenuator, millimeter wave technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of inability to meet continuous attenuation requirements, high cost, difficult processing and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

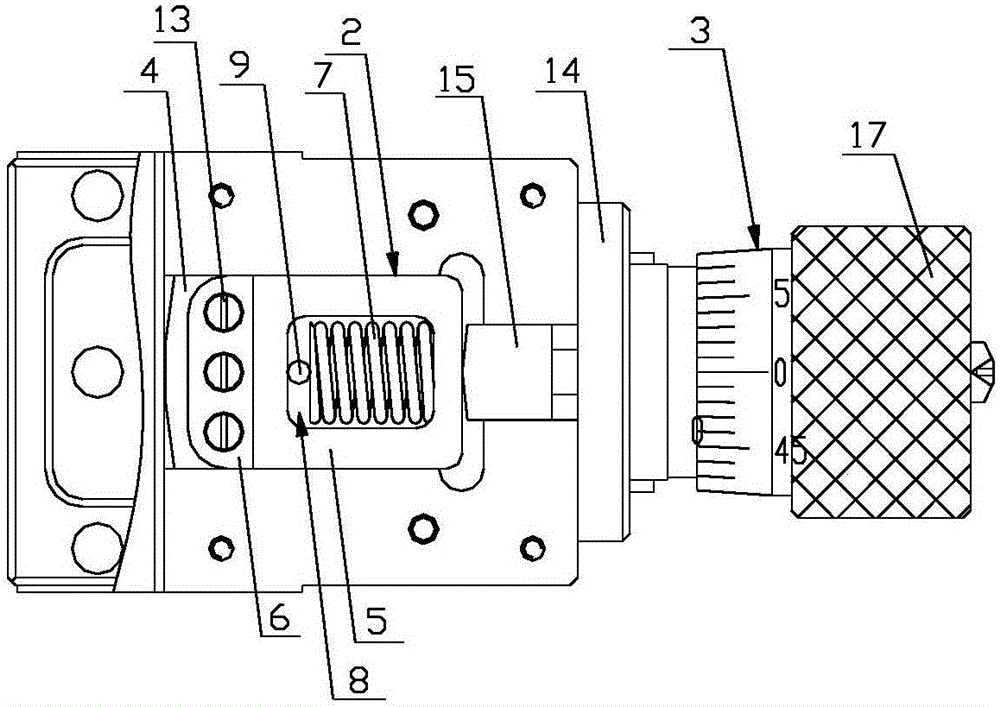

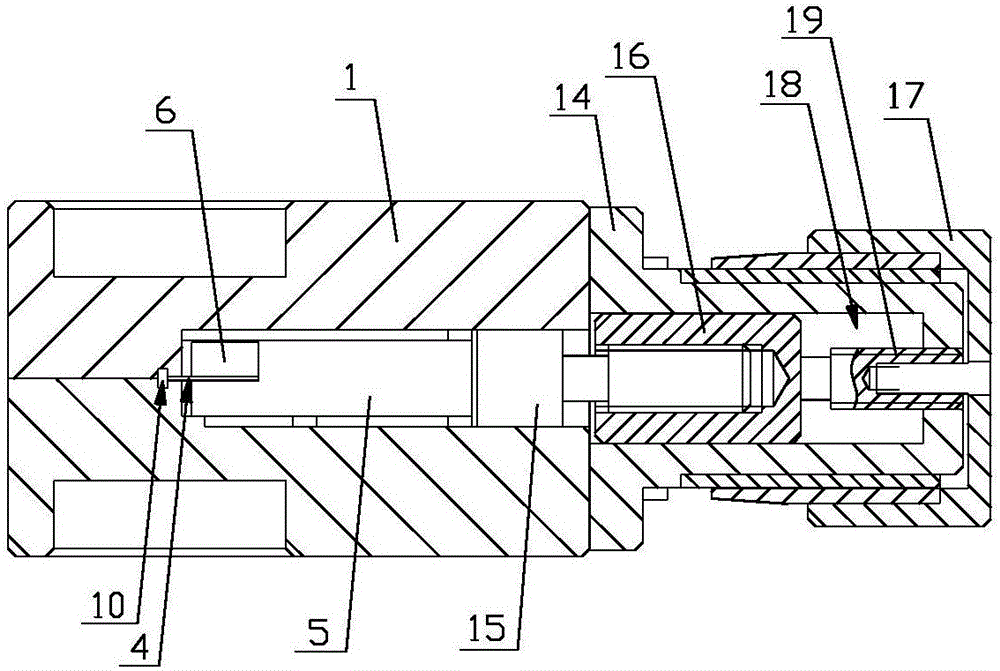

[0020] combine figure 1 and figure 2 As shown, a continuously adjustable millimeter-wave waveguide attenuator includes a waveguide component 1, an absorber component 2 and a differential helical fine-tuning component 3. A transmission waveguide 10 is provided on the waveguide assembly 1 .

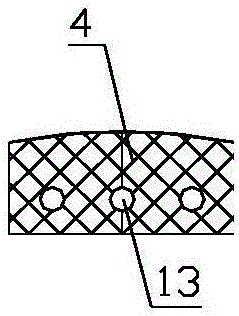

[0021] The absorber component 2 is placed inside the waveguide component 1 . The absorber assembly 2 includes an absorber 4 parallel to the surface of the transmission waveguide E, a slider 5 that can move left and right along the inside of the waveguide assembly 1 , a pressing block 6 and a spring 7 .

[0022] The absorber 4 is attached to the left end portion of the slider 5 through a pressure block 6 . A spring placement hole 8 is provided on the slider 5 for placing the spring 7 inside the slider. A pin 9 is installed on the waveguide assembly 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com