Submersible pump with watertight sealing structure designed with air jacking principle

A waterproof sealing, submersible pump technology, applied in the direction of pumps, pump devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

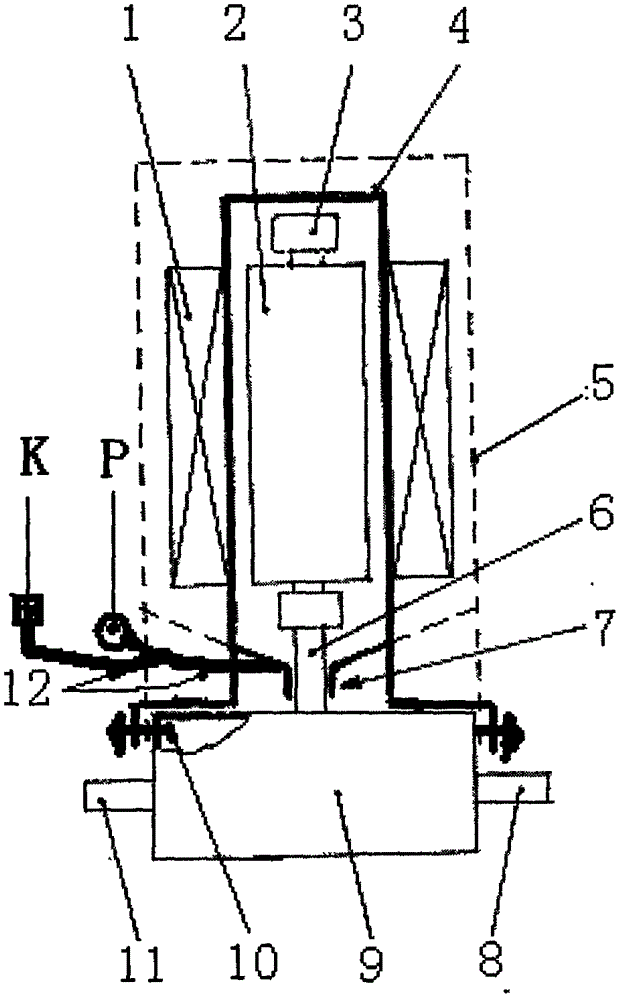

[0026] Overview of the core of the present invention: In order to prevent the motor rotor 2 from contacting with the external water body that penetrates into the submersible pump and eventually damage the motor, at least a metal-sealed isolation shielding cavity with a three-dimensional surrounding property is formed for the motor rotor, and only The rotating shaft 6 of the motor rotor 2 outputs rotational force to the liquid pump 9 through the shaft seal position 7. Obviously, if the external water body wants to enter the cavity (inner cavity) formed by the metal sealing isolation shield and contact with the motor rotor 2, then It can only enter through the shaft seal position 7 upwards along the rotating shaft 6. However, as long as the air pressure in the isolation and shielding cavity is large enough, it can fully support (prevent) the external water body from passing through the above-mentioned gap from top to bottom. The shaft seal position 7 enters the isolation shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com