Garlic root cutter and garlic clove machine

A technology of garlic and root cutting, applied in the fields of application, food processing, food science, etc., can solve the problems of slow root speed and large investment of garlic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

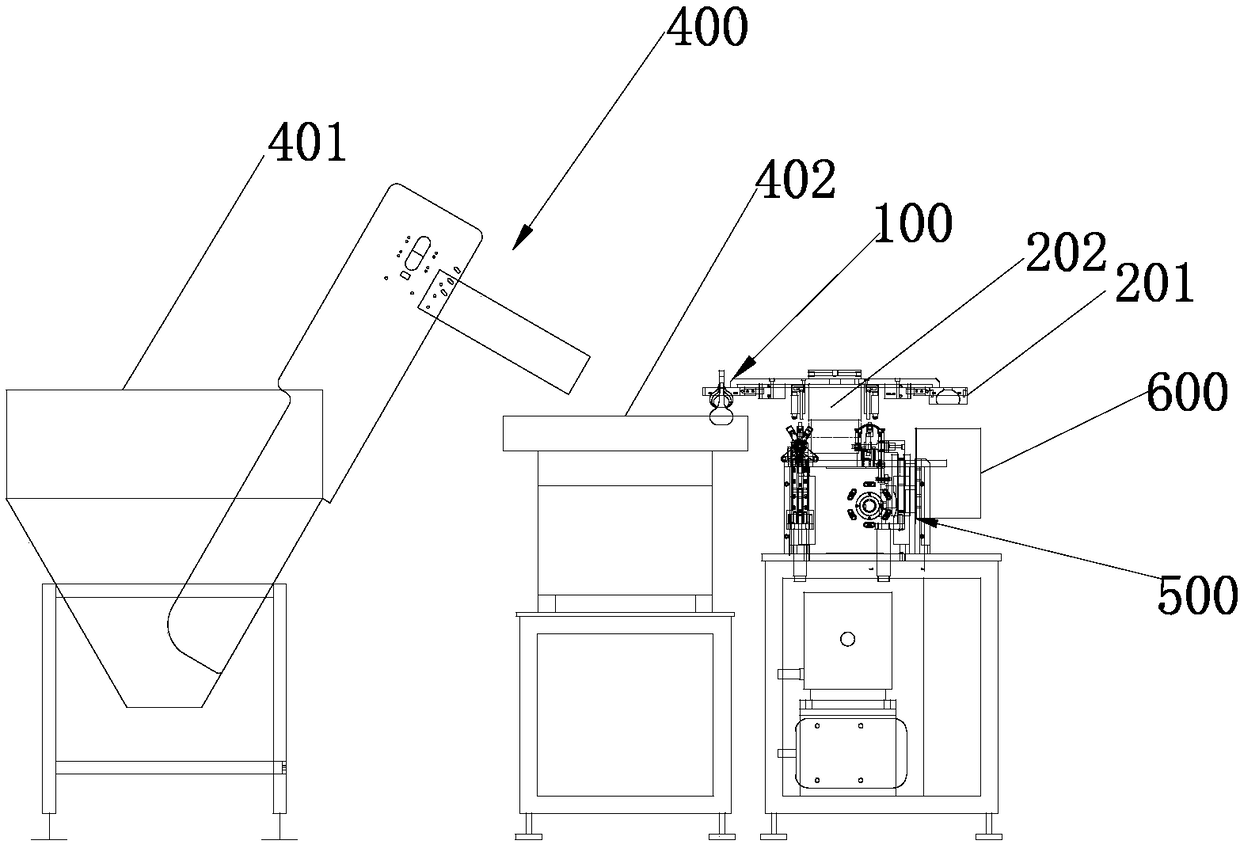

[0055] According to an embodiment of the garlic root cutting machine of the present invention, the garlic root cutting machine further includes: a transport device 600 installed on the frame and used for transporting away the garlic unloaded by the gripper mechanism at the unloading station.

[0056] According to the garlic root cutting machine of the present invention, the transport device 600 receives and transports the cut garlic at the unloading station, so that the cut garlic can be better collected and transported to the next step. Wait.

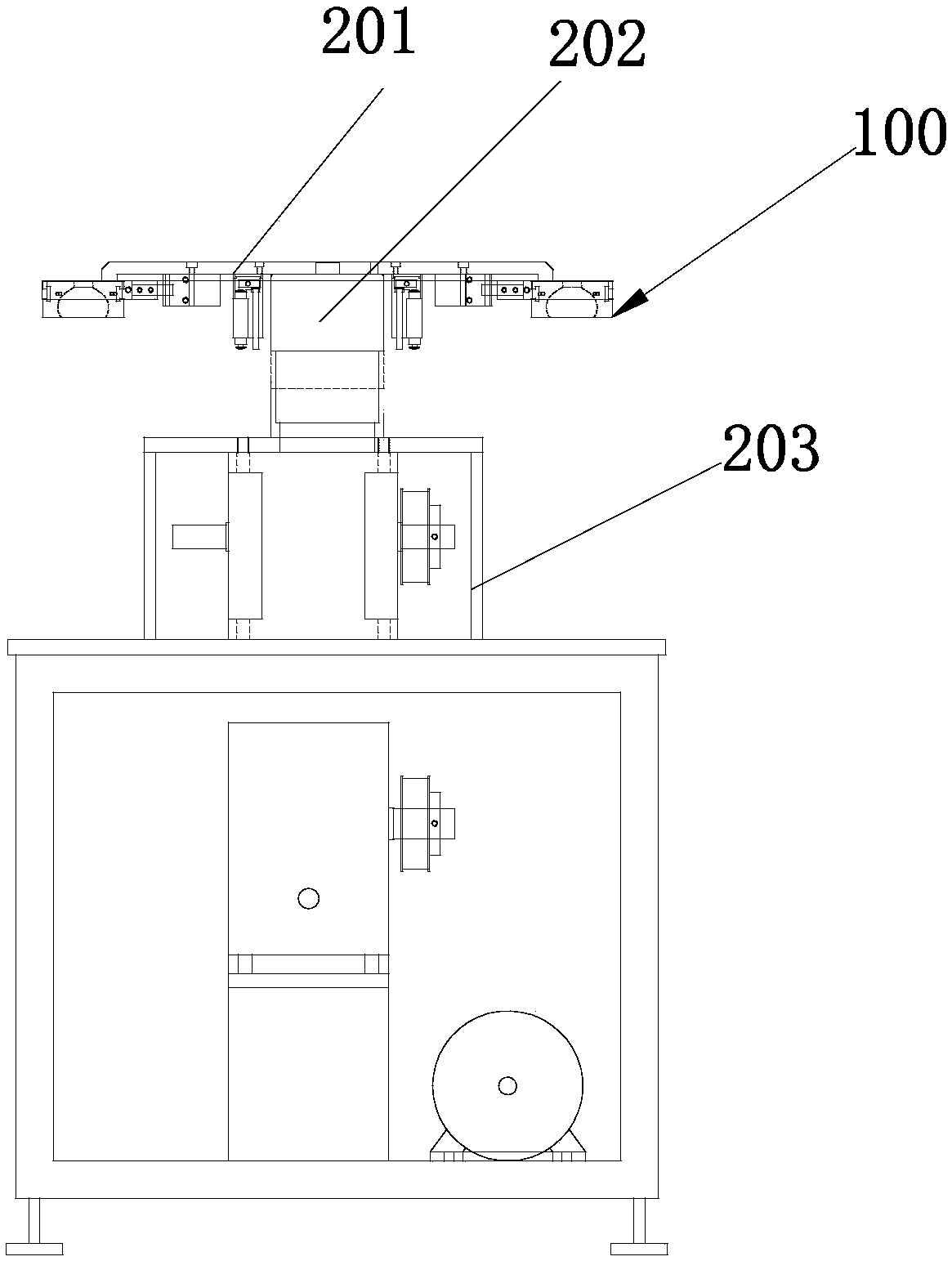

[0057] According to an embodiment of the garlic root cutter of the present invention, the first driving device includes: a rotating disk 201 and a divider 202;

[0058] The turntable 201 is installed on the divider 202, and the transfer mechanism is installed on the turntable 201;

[0059] The divider 202 is installed on the frame, and the divider 202 is used to adjust the height of the turntable along the axial direction, and drives ...

Embodiment 1

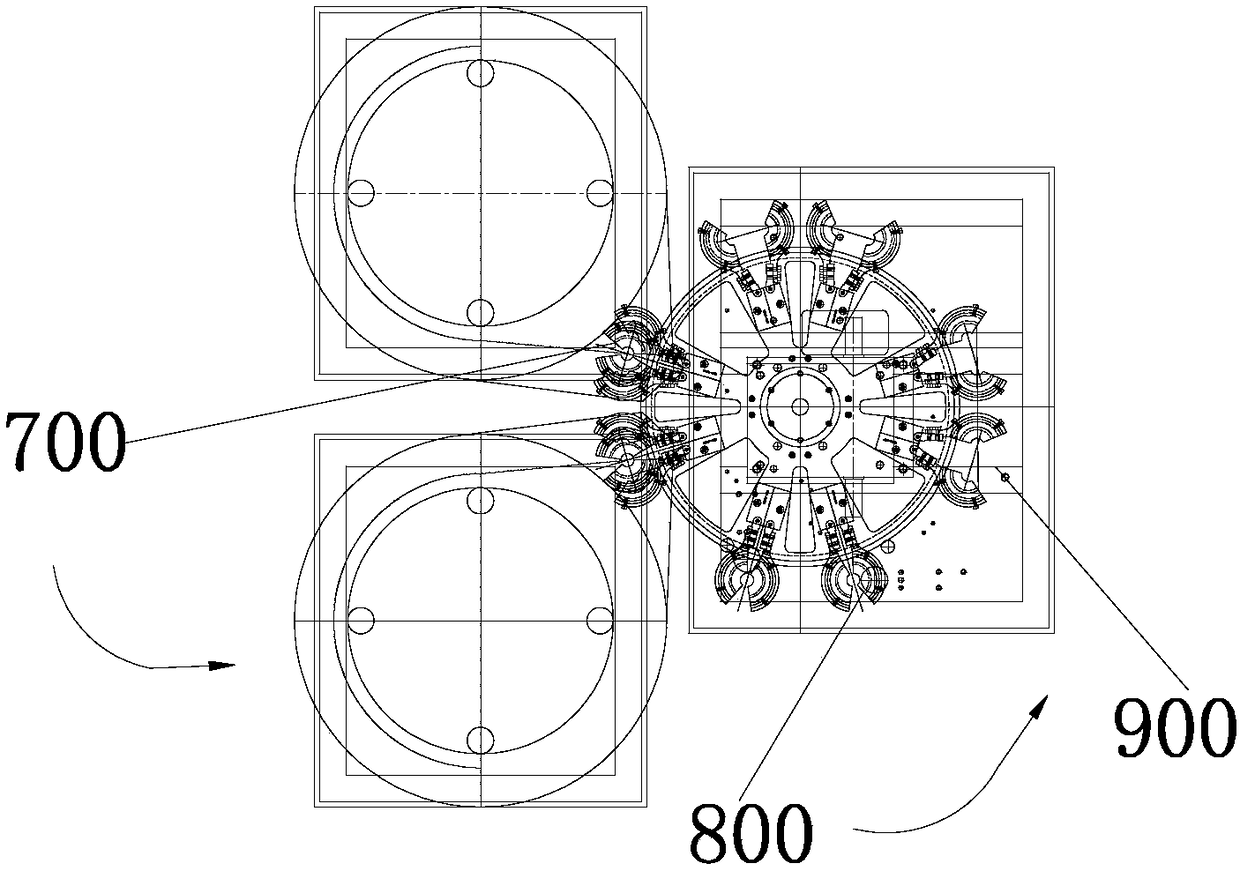

[0085] According to the garlic root cutting machine of the present invention, comprising: a frame, a handle mechanism 100, the handle mechanism 100 has a grasping station 700, a cutting station 800 and a discharge station 900; a first driving device; a second driving device ; Conveying device 400; Cutting device 500 and material transport device 600;

[0086] The hoist 401 places the garlic to be cut on the vibrating plate 402, and the vibrating plate 402 is used to sequentially transport the garlic to be cut to the grasping station 700; Above, the divider 202 drives the rotation of the turntable 201 through the motor and the reducer and adjusts the height of the turntable 201, and at the same time, the second driving device drives the finger 101 to switch from the open state to the closed state to switch the gripper from the open state to the closed state , the gripper mechanism 100 grabs the garlic to be cut on the grabbing station 700; the turntable 201 transfers the garlic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap