Annular space type centrifugal extractor and interface radius control method thereof

A centrifugal extractor and annulus-type technology, which is applied in separation methods, solvent extraction, chemical instruments and methods, etc., and can solve problems such as difficulty in adjusting the interface radius of annulus-type centrifugal extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

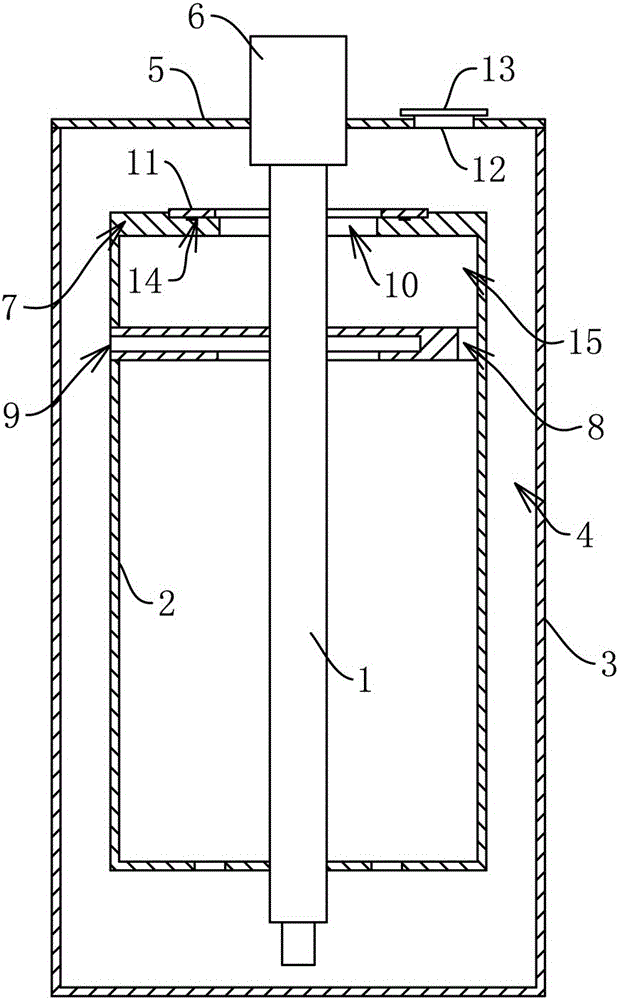

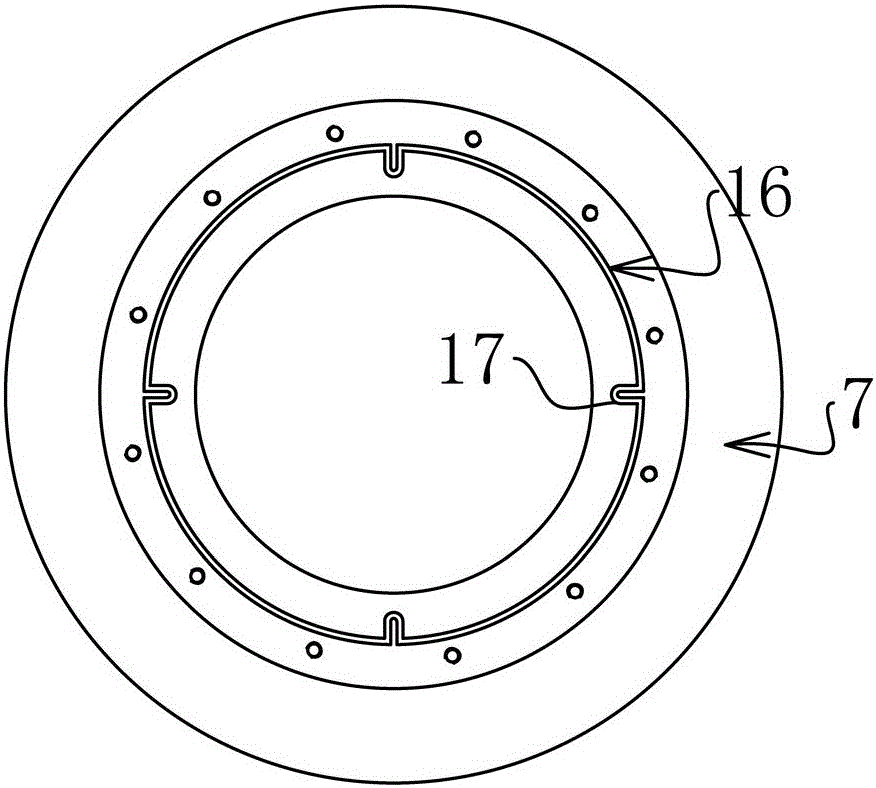

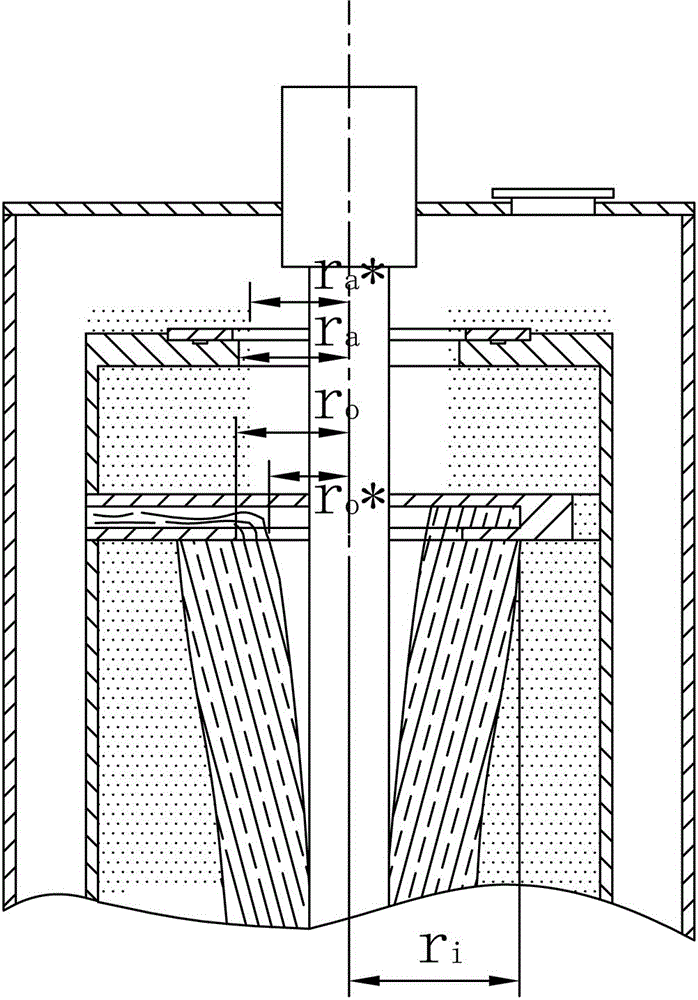

[0022] Examples of annulus centrifugal extractors: such as figure 1 with figure 2 As shown, it includes a rotating shaft 1, a rotating drum 2 and a cylindrical shell 3. The shell 3 is sleeved with the rotating drum 2 and an annular gap 4 is provided between the shell 3 and the rotating drum 2. The shell 3 is provided with heavy and light phase inlets, and the shell 3 The bottom is closed and the upper end is provided with a cover plate 5. The rotating drum 2 and the rotating shaft 1 are in rotation-stop fit. The upper end of the rotating shaft 1 is connected with a motor 6 fixedly connected with the cover plate 5, forming the motor 6 to drive the rotating drum 2 through the rotating shaft 1 to rotate at a high speed The bottom of the drum 2 is provided with a bottom plate and the bottom plate is provided with an inlet communicating wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com