Cutting and pricking device of fiber cord fabric cutting machine

A cutting machine and cord technology, which is applied in the field of tire production, can solve problems such as fiber cord position deviation, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

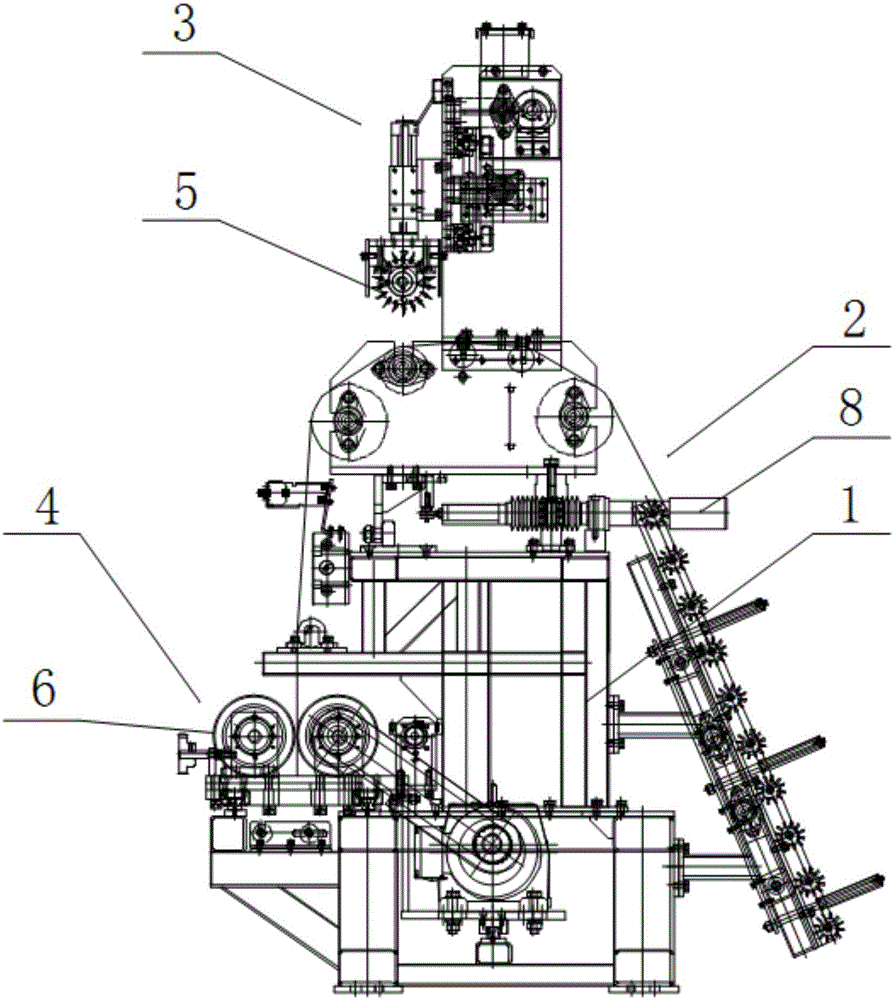

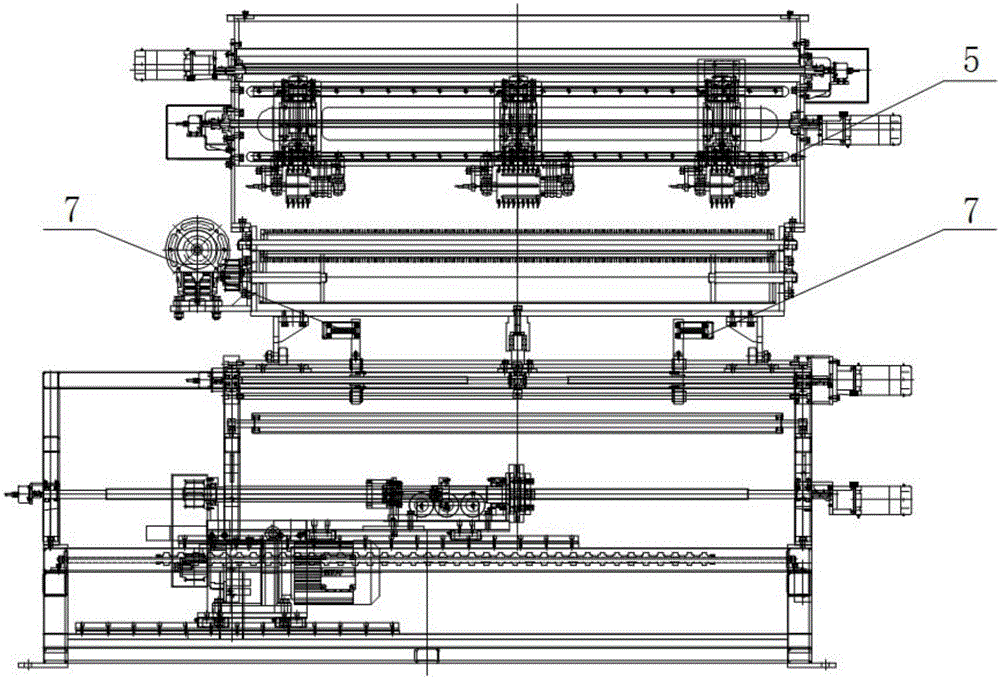

[0014] Such as figure 1 , 2 As shown, a cutting and piercing device of a fiber cord cutting machine includes a frame 1, a centering device 2, a piercing device 3 and a cutting device 4; the centering device 2 is arranged on the frame 1 One side is used to align the central position of the fiber cords transported by the cord conveyor belt; the piercing device 3 is arranged on the top of the frame and includes a plurality of licker-in rollers 5 for piercing the fiber cords; the cutting The device 4 is arranged on the other side of the frame and includes a cutting cutter head 6 for cutting the perforated fiber cord into a set width.

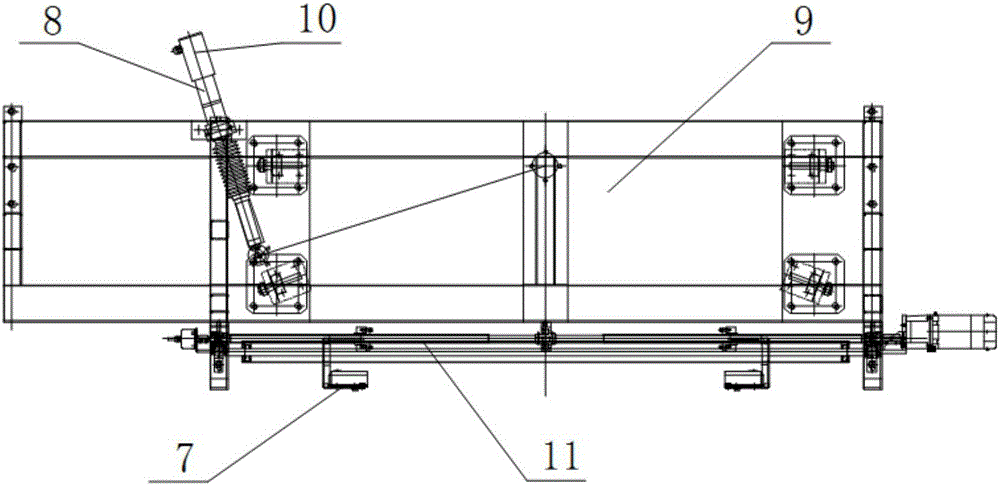

[0015] Such as image 3 As shown, the centering device 2 includes two position sensors 7 and a deviation correction device respectively arranged on both sides of the fiber cord; the position sensor 7 is used to detect the edge position of the fiber cord; the deviation correction device includes a deviation correction conveying plate 9 And the dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap