Press machine

A technology of presses and templates, applied in the field of presses, can solve the problems of affecting the working environment of workers, increasing costs, large size and weight of presses, etc., and achieving the effects of avoiding excessive movement, improving utilization, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

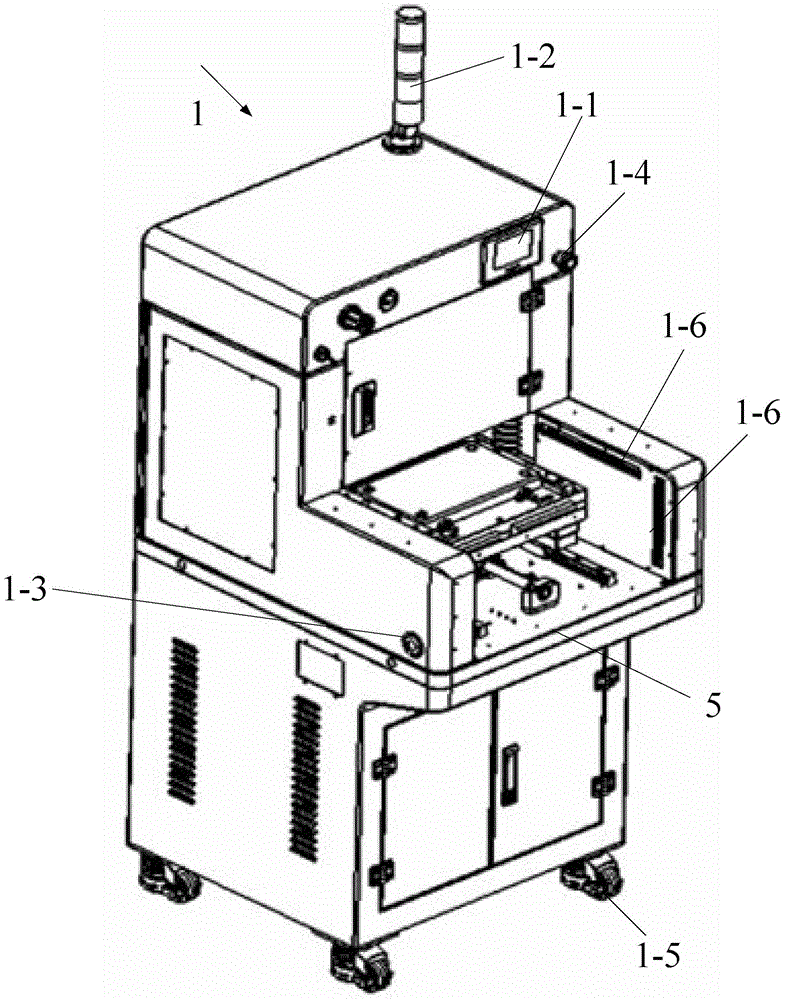

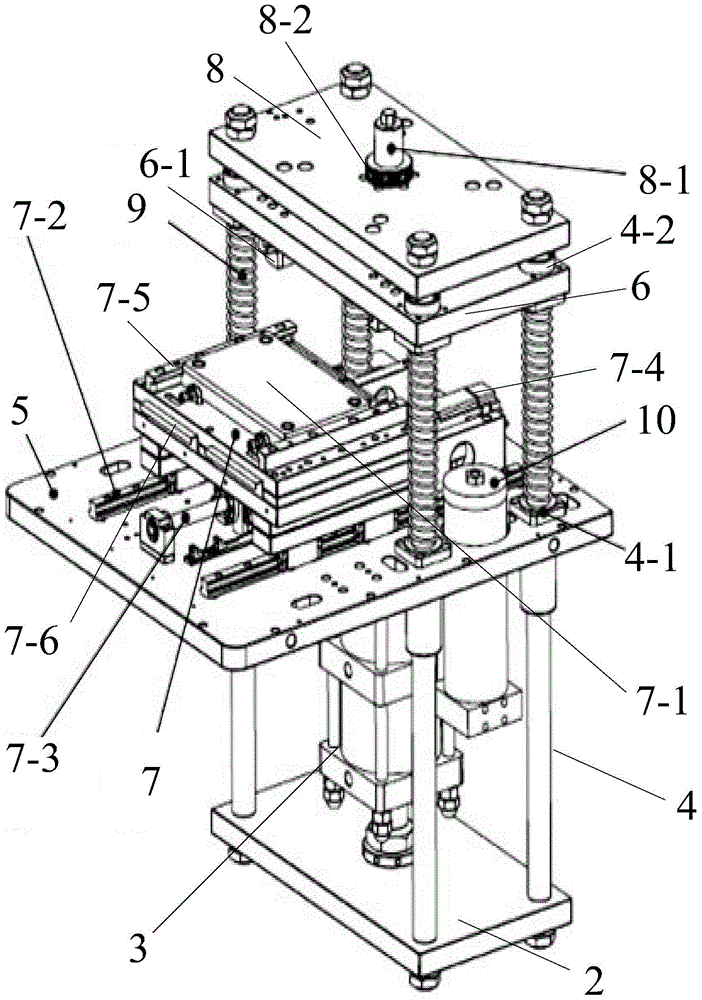

[0018] Please refer to figure 1 and figure 2 , a press, comprising a box 1, the box 1 is provided with a control system, a bottom plate 2, a cylinder 3, a guide column 4, a support platform 5 fixedly connected with the box 1, and an upper template carrier 6 , the upper formwork set on the upper formwork support plate 6, the height adjustment plate 8 for adjusting the height of the upper formwork support plate 6, the lower formwork carrying device 7 slidably connected with the support table 5, and the The lower formwork 7-1 on the lower formwork carrying device 7; one end of the cylinder 3 is fixedly connected to the base plate 2, and the other end is fixedly connected to the support platform 5; the lower end of the guide column 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com