Automatic packaging machine

A packaging machine and packaging technology, applied in the field of packaging, can solve the problems of current fluctuation, affecting the normal operation of the packaging machine, and easy to burn out the motor, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

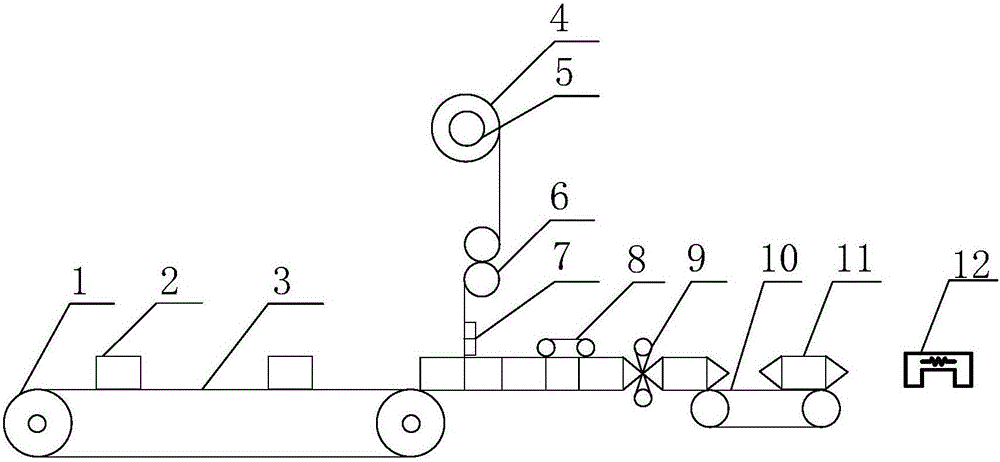

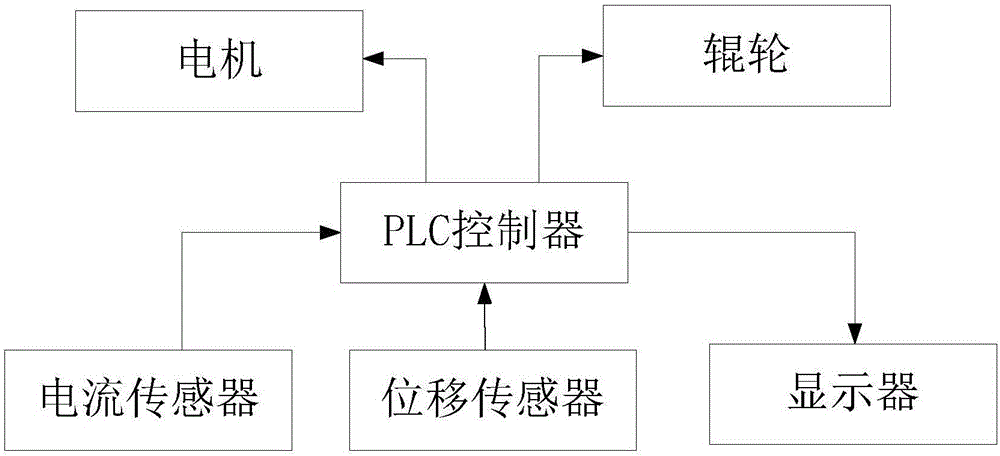

[0016] An automatic packaging machine, including a transmission mechanism, a film feeding mechanism, a packaging mechanism, a transportation mechanism 10 and an automatic control mechanism 12; the automatic packaging machine is driven by a motor;

[0017] The conveying mechanism includes two conveying rollers 1 and a conveyor belt 3, on which the object to be packaged 2 is placed, and the conveying roller 1 drives the conveyor belt 3 to transport the object to be packaged 2;

[0018] Described film sending mechanism comprises film sending roller 5 and film pulling roller 6, and film sending roller 5 is wrapped with roll packaging film 4, and film pulling roller 6 is placed below film sending roller 5, for Pull wrapping film 4;

[0019] The packaging mechanism includes a forming device 7, a leveling device 8 and a seam sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap