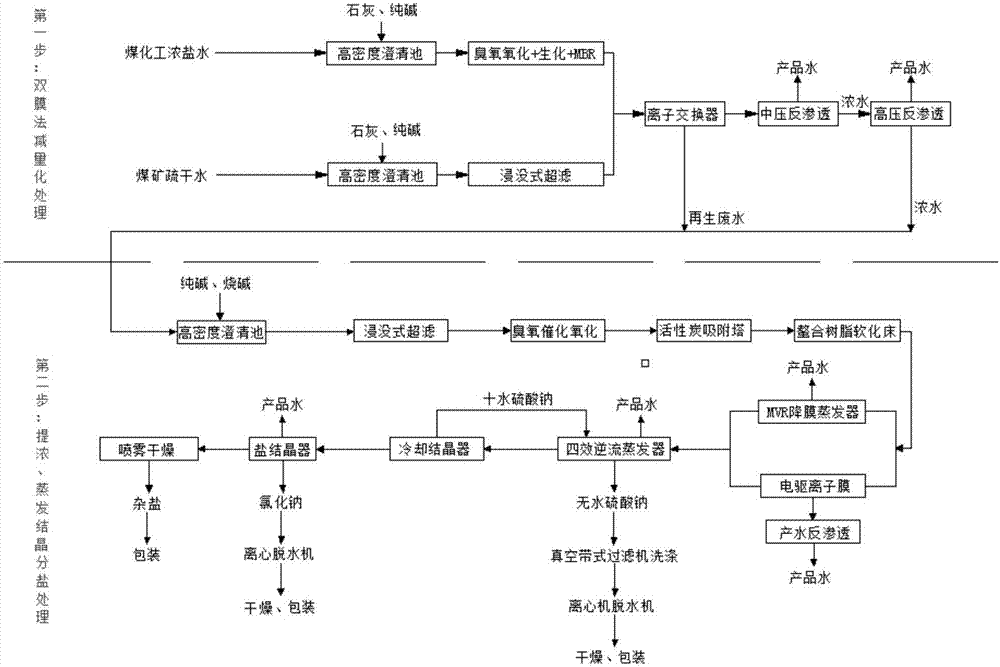

A salt separation process for industrial wastewater

A technology for industrial wastewater and coal chemical wastewater, which is applied in general water supply conservation, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing emissions, simple and feasible technical solutions, and reducing costs and pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

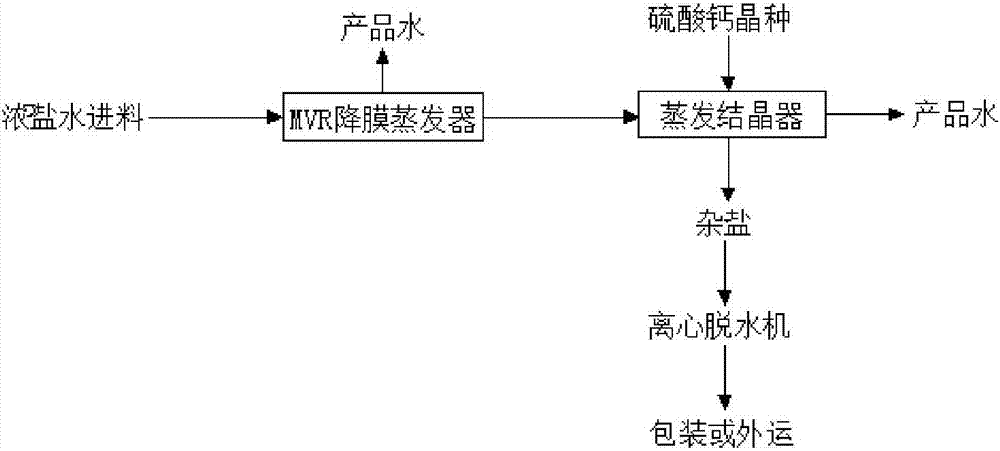

Method used

Image

Examples

Embodiment 1

[0059] 1. Coal chemical wastewater pretreatment

[0060] (1) will 100m 3 The TDS / h is 5560mg / L coal chemical wastewater into the high-density clarifier, and add 2kg / m 3 A mixture of an appropriate amount of polyferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide, and polyacrylamide (the weight ratio of polyferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide, and polyacrylamide is: 50: 20:10:5:5), filter the sediment, soften the water;

[0061] (2) the water to be treated in step (1) passed through ozone for 1 hour, then measure the B / C value;

[0062] (3) The wastewater oxidized by ozone in step (2) flowed to the biochemical pool for reaction for 12 hours;

[0063] (4) When the oxygen supply is 95%, the waste water in step (3) is filtered and adsorbed through the MBR membrane biological reaction tank; then the filtered water is sent to the ion exchanger for deep softening treatment, and sent Go to the next step of desalination treatment;...

Embodiment 2

[0081] 1. Coal chemical wastewater pretreatment

[0082] (1) will 200m 3 The TDS / h is 5560mg / L coal chemical wastewater into the high-density clarifier, and add 5kg / m 3 The mixture of polymerized ferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide and polyacrylamide (the weight ratio of polymerized ferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide and polyacrylamide is: 175:60: 30:15:12), filter sediment, water softening;

[0083] (2) the water to be treated in step (1) passed through ozone for 2 hours, then measure the B / C value;

[0084] (3) The wastewater oxidized by ozone in step (2) flowed to the biochemical pool for reaction for 18 hours;

[0085] (4) When the oxygen supply is 100%, the waste water in step (3) is filtered and adsorbed through the MBR membrane bioreactor; then the filtered water is sent to the ion exchanger for deep softening treatment, and sent Go to the next step of desalination treatment; the ion exchanger is r...

Embodiment 3

[0103] 1. Coal chemical wastewater pretreatment

[0104] (1) will be 300m 3 The TDS / h is 7280mg / L coal chemical wastewater into the high-density clarifier, and add 8kg / m 3 A mixture of polymeric ferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide and polyacrylamide (the weight ratio of polymeric ferric sulfate, sodium carbonate, calcium hydroxide, sodium hydroxide and polyacrylamide is 300:100:50 :25:20), filter sediment, water softening;

[0105] (2) the water to be treated in step (1) was passed through ozone for 1-3 hours, then measure the B / C value;

[0106] (3) The wastewater oxidized by ozone in step (2) flowed to the biochemical pool for reaction for 24 hours;

[0107] (4) When the oxygen supply is 100%, the waste water in step (3) is filtered and adsorbed through the MBR membrane bioreactor; then the filtered water is sent to the ion exchanger for deep softening treatment, and sent Go to the next step of desalination treatment; the ion exchanger i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com