Effective low-foam laundry detergent

A laundry liquid and high-efficiency technology, applied in detergent compositions, non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, etc., can solve the problems of difficult rinsing of foam, and achieve good defoaming effect and easy rinsing. , the effect of strong decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

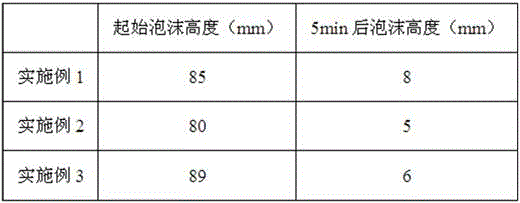

Examples

Embodiment 1

[0014] This high-efficiency low-foaming laundry detergent is made of the following components:

[0015] 6000g saponins, 4000g neem leaves, 3000g tea bran, 500g palm oil, 100g baking soda, 100g sodium stearate, 100g sodium silicate and 10000g deionized water.

[0016] The preparation method is as follows: extract the active ingredients of saponins, neem leaves and tea bran with water respectively, then concentrate under reduced pressure, mix them evenly with palm oil, baking soda, sodium stearate and sodium silicate, and finally dissolve them in prepared in deionized water.

Embodiment 2

[0018] This high-efficiency low-foaming laundry detergent is made of the following components:

[0019] 7500g saponins, 4800g neem leaves, 4500g tea bran, 800g palm oil, 500g baking soda, 500g sodium stearate, 500g sodium silicate and 10000g deionized water.

[0020] The preparation method is as follows: extract the active ingredients of saponins, neem leaves and tea bran with water respectively, then concentrate under reduced pressure, mix them evenly with palm oil, baking soda, sodium stearate and sodium silicate, and finally dissolve them in prepared in deionized water.

Embodiment 3

[0022] This high-efficiency low-foaming laundry detergent is made of the following components:

[0023] 6800g saponins, 4400g neem leaves, 4000g tea bran, 700g palm oil, 300g baking soda, 400g sodium stearate, 200g sodium silicate and 10000g deionized water.

[0024] The preparation method is as follows: extract the active ingredients of saponins, neem leaves and tea bran with water respectively, then concentrate under reduced pressure, mix them evenly with palm oil, baking soda, sodium stearate and sodium silicate, and finally dissolve them in prepared in deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com