A washing machine spray structure, washing machine and spraying method

A washing machine and spray head technology, which is applied to other washing machines, washing devices, textiles and paper making, etc., and can solve problems such as excessive spraying range and water leakage of washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

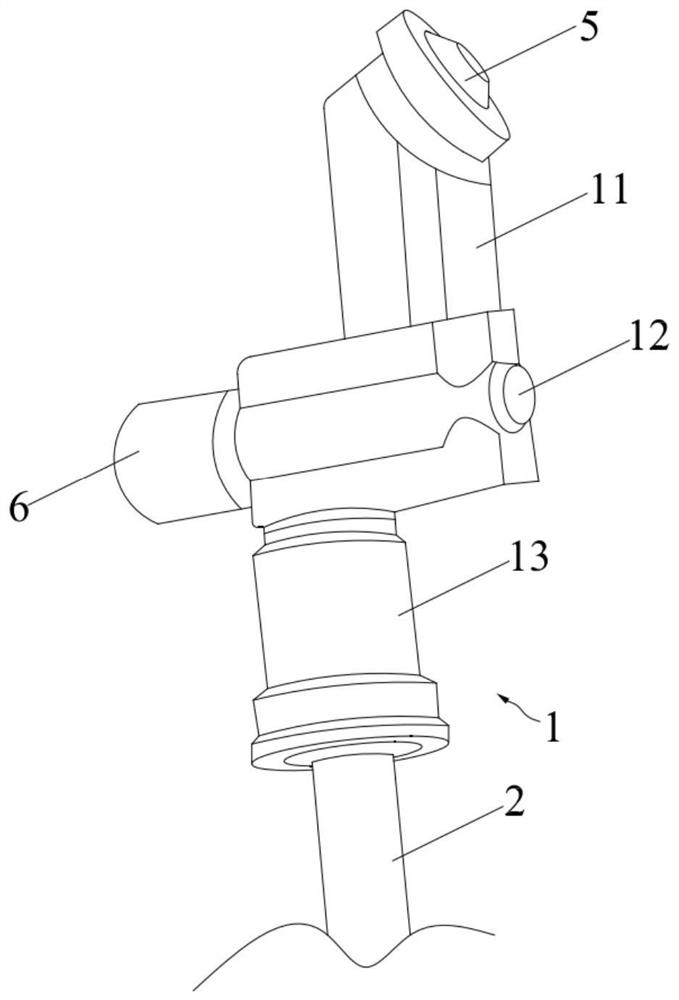

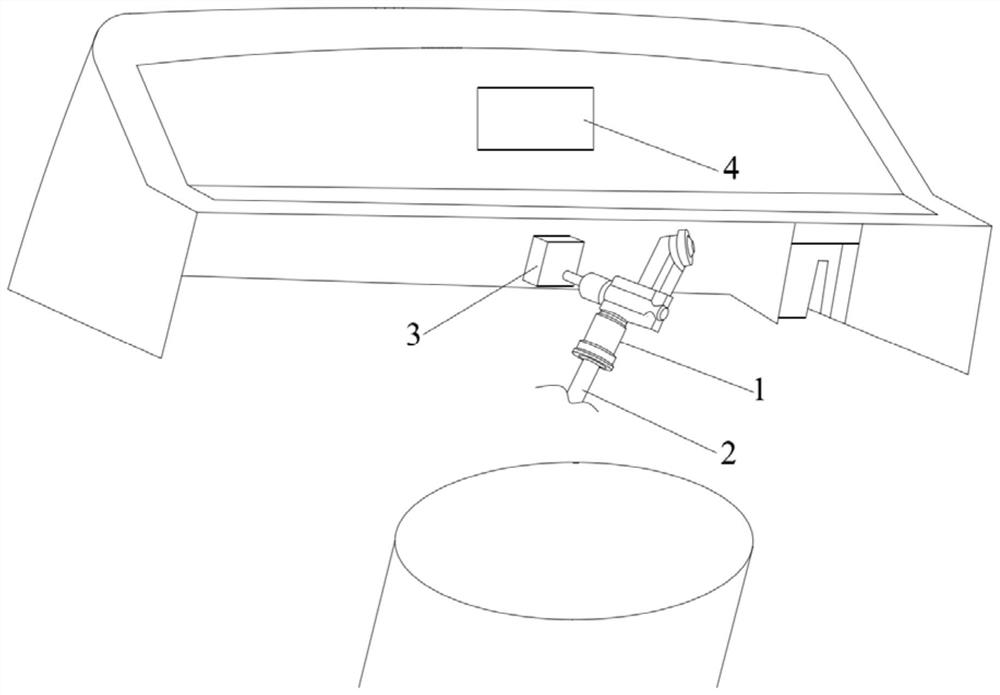

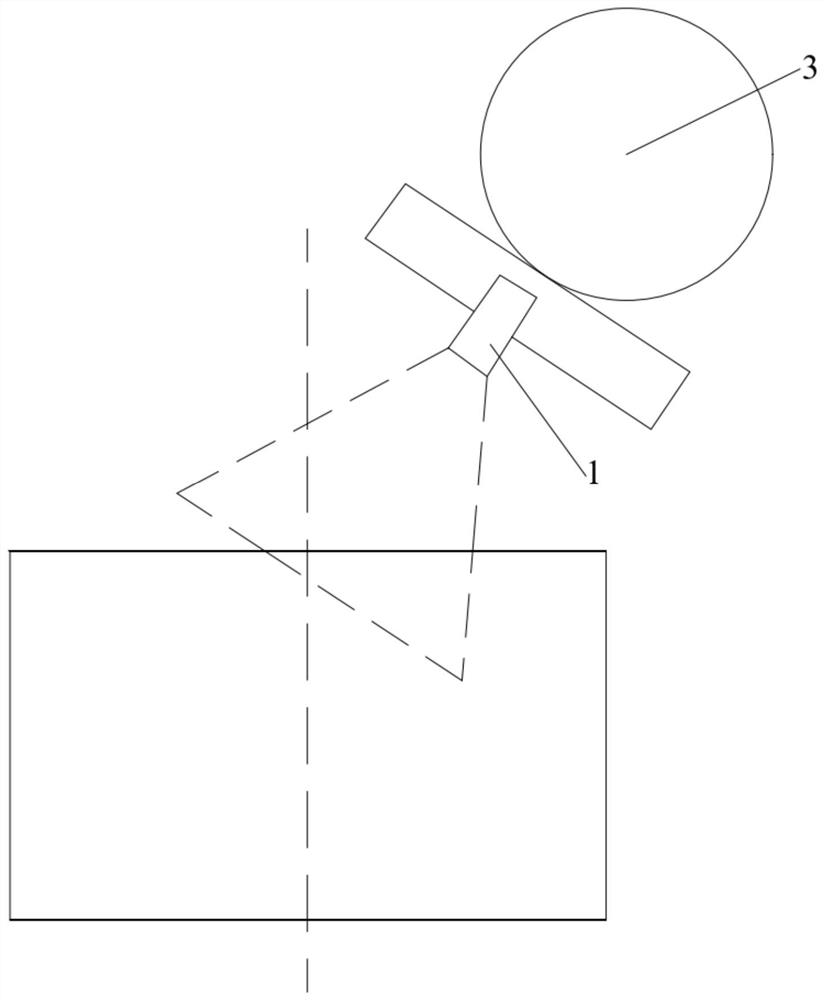

[0037] This embodiment provides a washing machine spray structure, the spray structure in this embodiment is described by taking the pulsator washing machine as an example, refer to figure 1 and figure 2 , the spray head 1 arranged in the outer tub is used to spray into the inner tub of the washing machine and can rotate relative to the outer tub; the water supply assembly connected to the spray head 1 supplies the spray head 1 with external water; The drive assembly 3 is connected to the spray head 1 to drive the spray head 1 to rotate relative to the outer barrel; the computer board 4 is electrically connected to the spray head 1, the water supply assembly and the drive assembly 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com