A gear ring rotation limiting mechanism

A technology of rotation limit and ring gear, which is applied in the direction of manipulators, mechanical equipment, belts/chains/gears, etc., can solve problems such as out-of-control joint rotation and complicated control procedures of the drive system, and achieve the effect of scientific design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

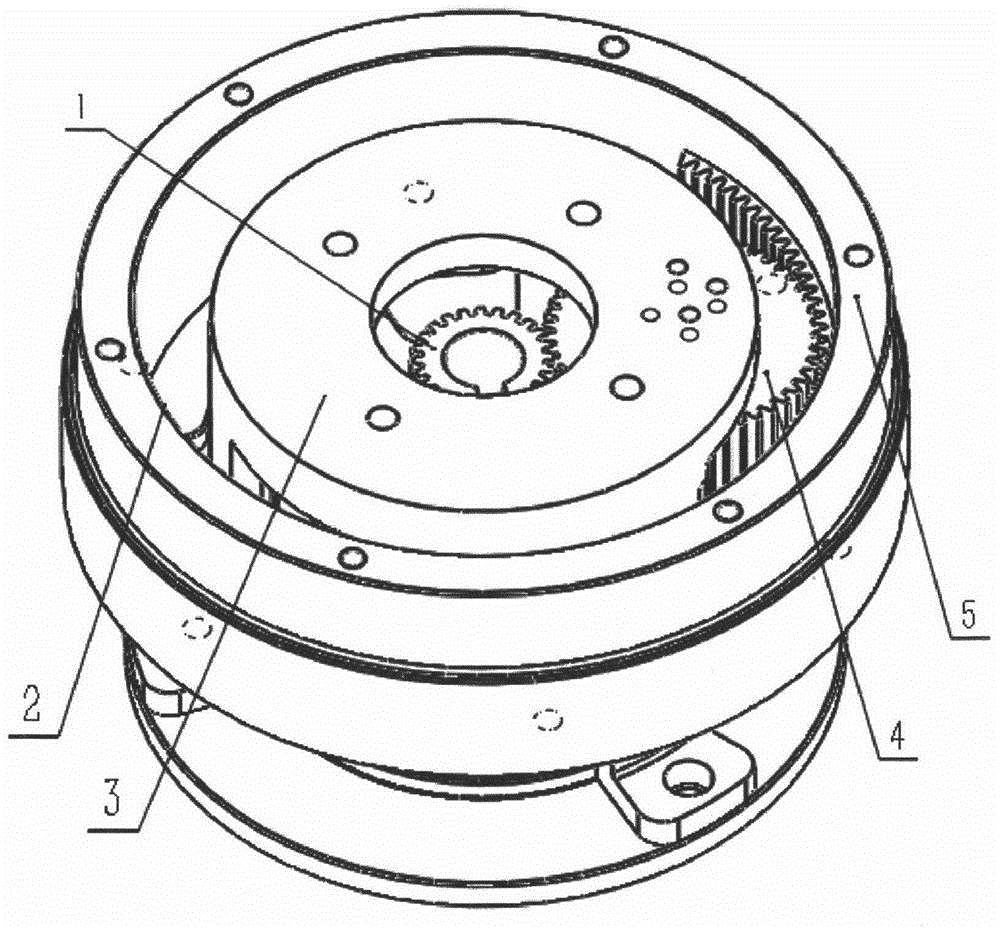

[0021] A ring gear rotation limiting mechanism includes a driving gear, a rotating flange, a fixed flange, an intermediate idler, and a ring gear; the driving gear and the intermediate idler are installed on the fixed flange, and the driving gear drives the ring gear to rotate through the intermediate idler. The ring gear is mounted on the rotating flange and driven to rotate by the ring gear.

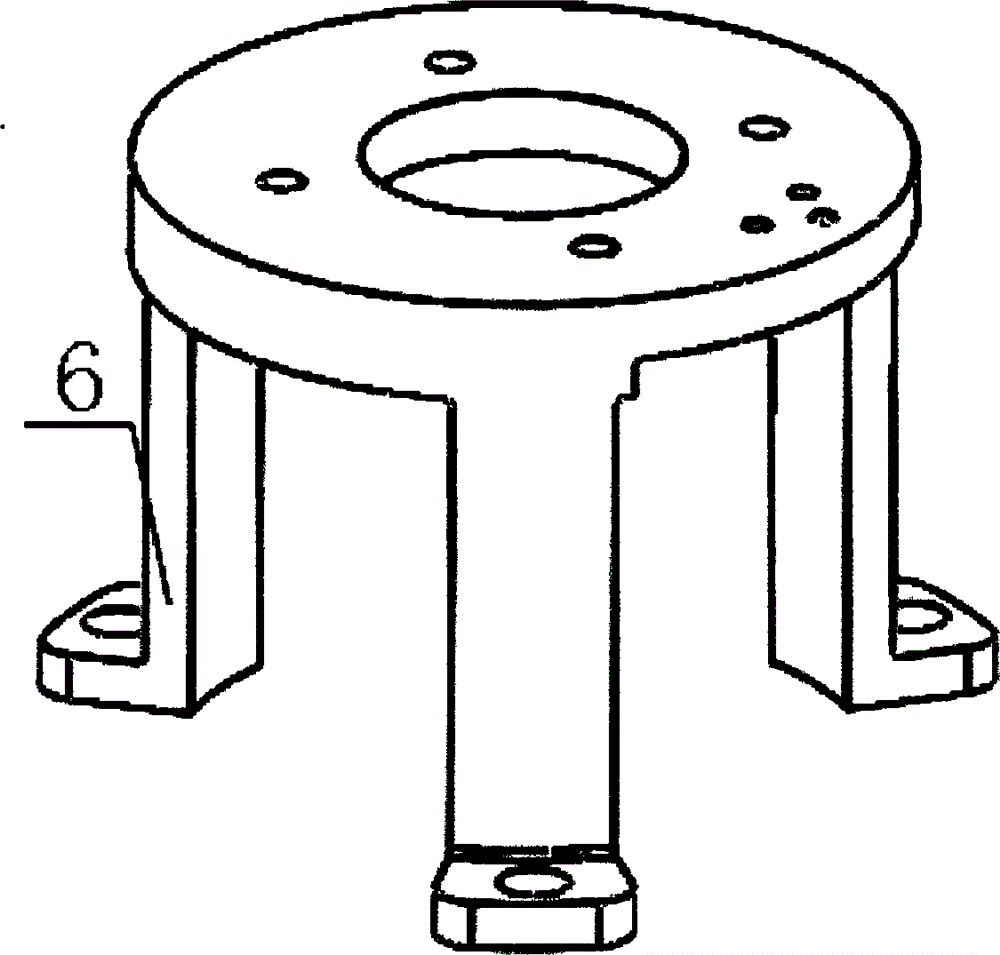

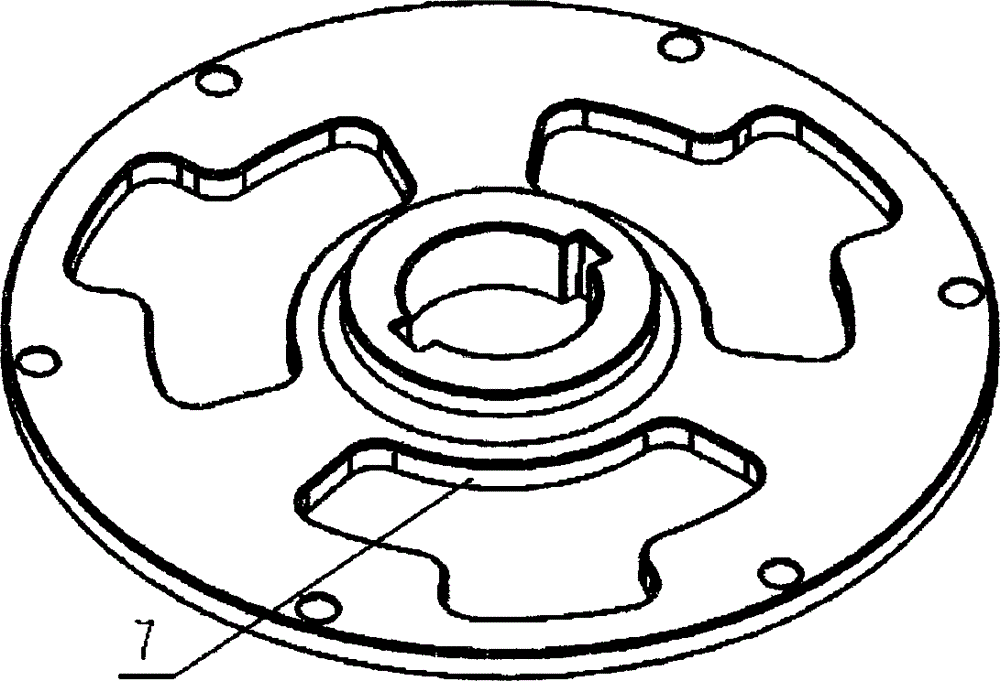

[0022] The fixed flange has outriggers, which are installed and fixed through the outriggers, and the outriggers are evenly distributed on the periphery of the flange; the rotating flange has annular fan-shaped grooves; the legs of the fixed flange pass through the annular fan-shaped grooves of the rotating flange. The ring gear is an incomplete internal gear, the number of teeth depends on the rotation angle allowed by the rotation of the rotating flange. The length of the circular fan-shaped groove arc of the rotating flange depends on the allowable rotation angle of the rotating fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com