Installation structure and ventilation system of heat exchange core

A technology of heat exchange core and installation structure, applied in the field of heat exchange core installation structure and ventilation system, can solve the problem that the sealing effect cannot be guaranteed, the tight fit cannot be guaranteed, the sealing strip cannot be guaranteed to be uniformly stressed and the best compression state, etc. problem, to achieve the effect of compact structure, good sealing effect, and prevention of mutual mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, an installation structure of a heat exchange core according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

[0028] Aiming at the sealing installation of the heat exchange core, the present invention proposes a new installation structure, which can be applied to various ventilation systems (such as fresh air systems or air-conditioning systems with fresh air functions, etc.).

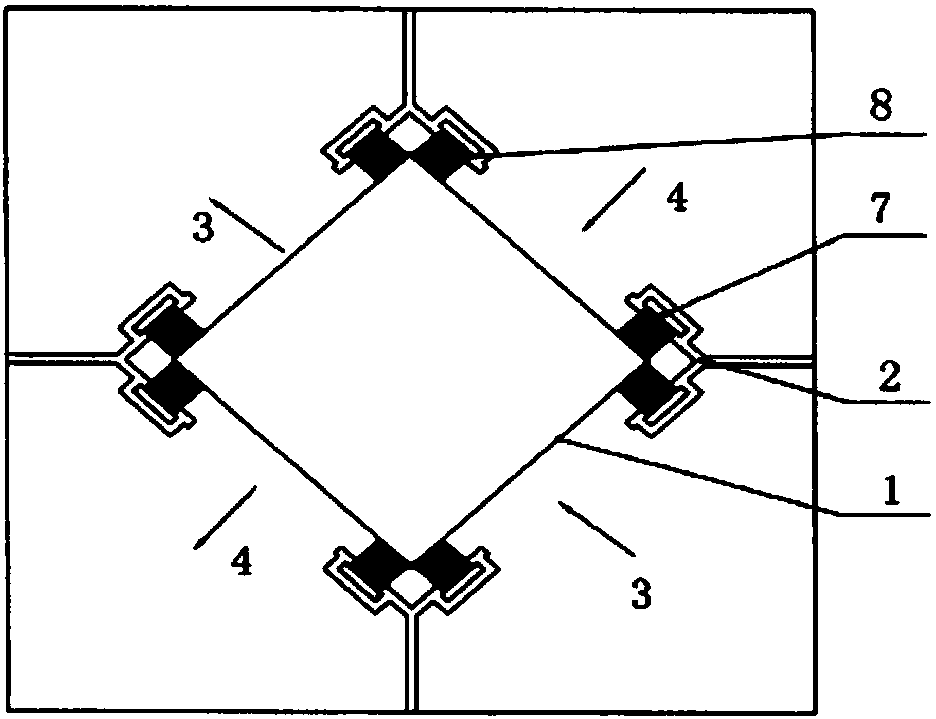

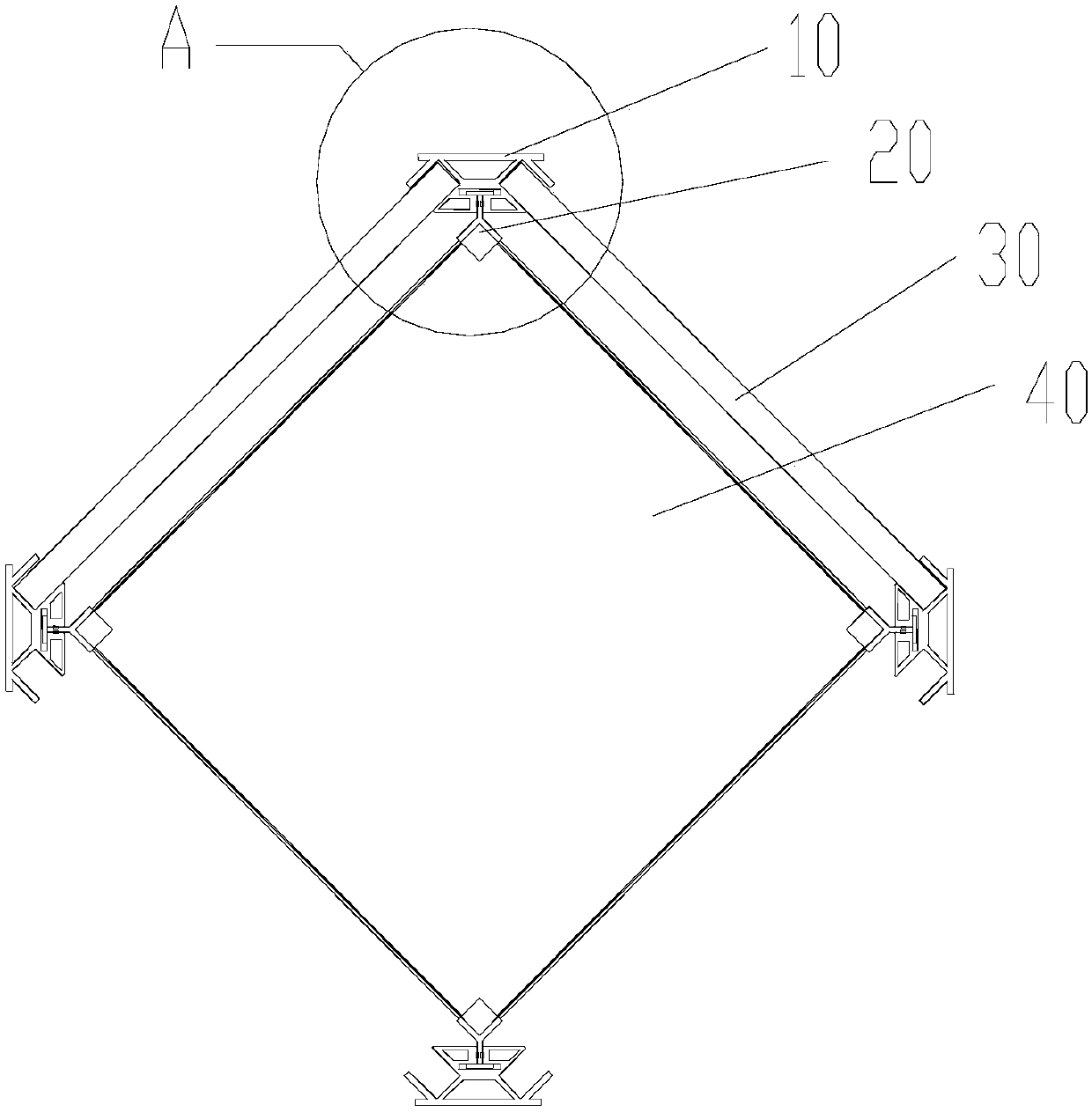

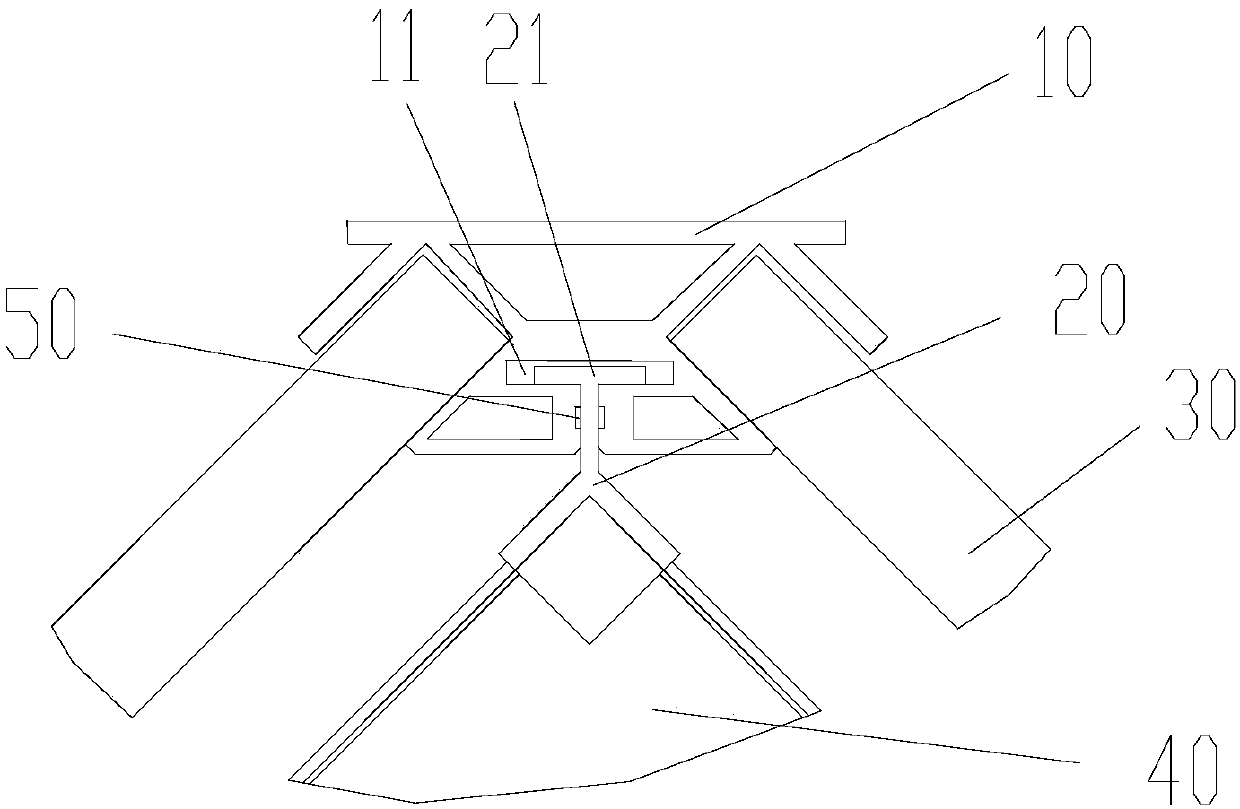

[0029] Such as figure 2 and image 3 As shown, the installation structure of the heat exchange core 40 of the present invention includes a first structural member 10 for installing the heat exchange core 40 and a second structural member 20 fixed relative to the heat exchange core 40 . Among them, such as image 3 As shown, the first structural member 10 includes a T-shaped slot 11, and the second structural member 20 includes a T-shaped member 21, and the T-shaped member 21 is installed in the T-shaped slot 11 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com