Protective cover for proximity sensor

A technology of a proximity sensor and a proximity sensor, which is applied in the field of protective sleeves and can solve problems such as sensing errors, false triggers, and proximity sensor 10 sensing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

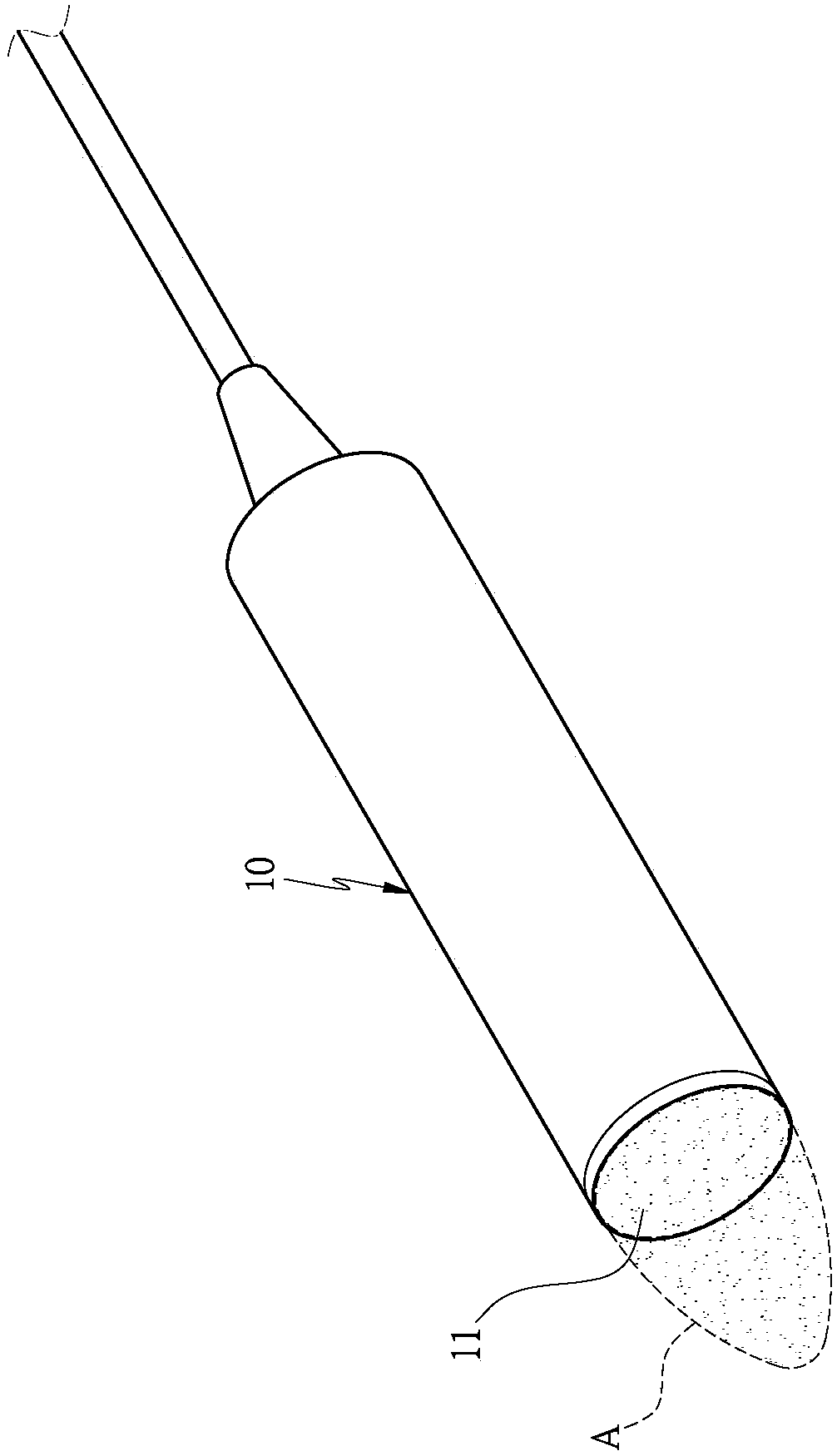

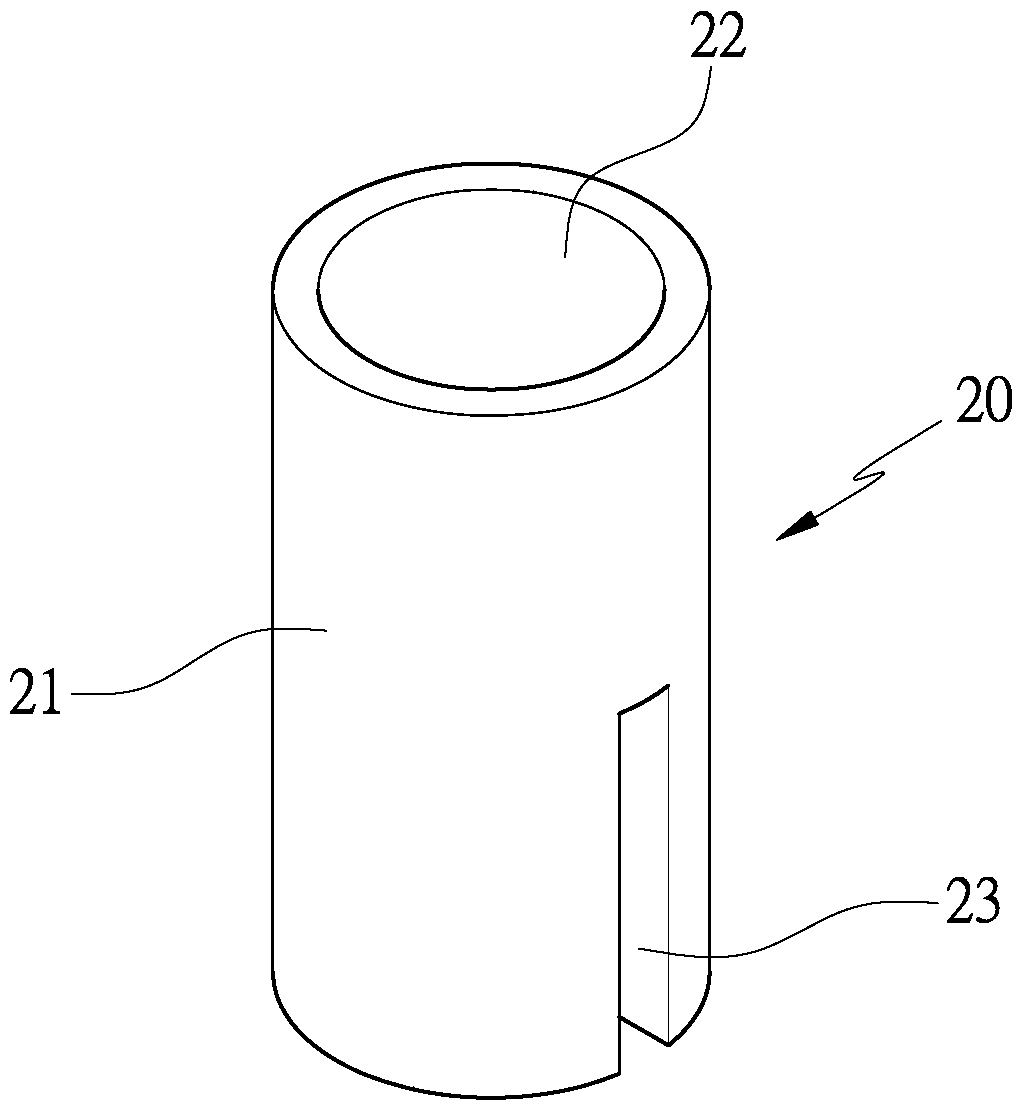

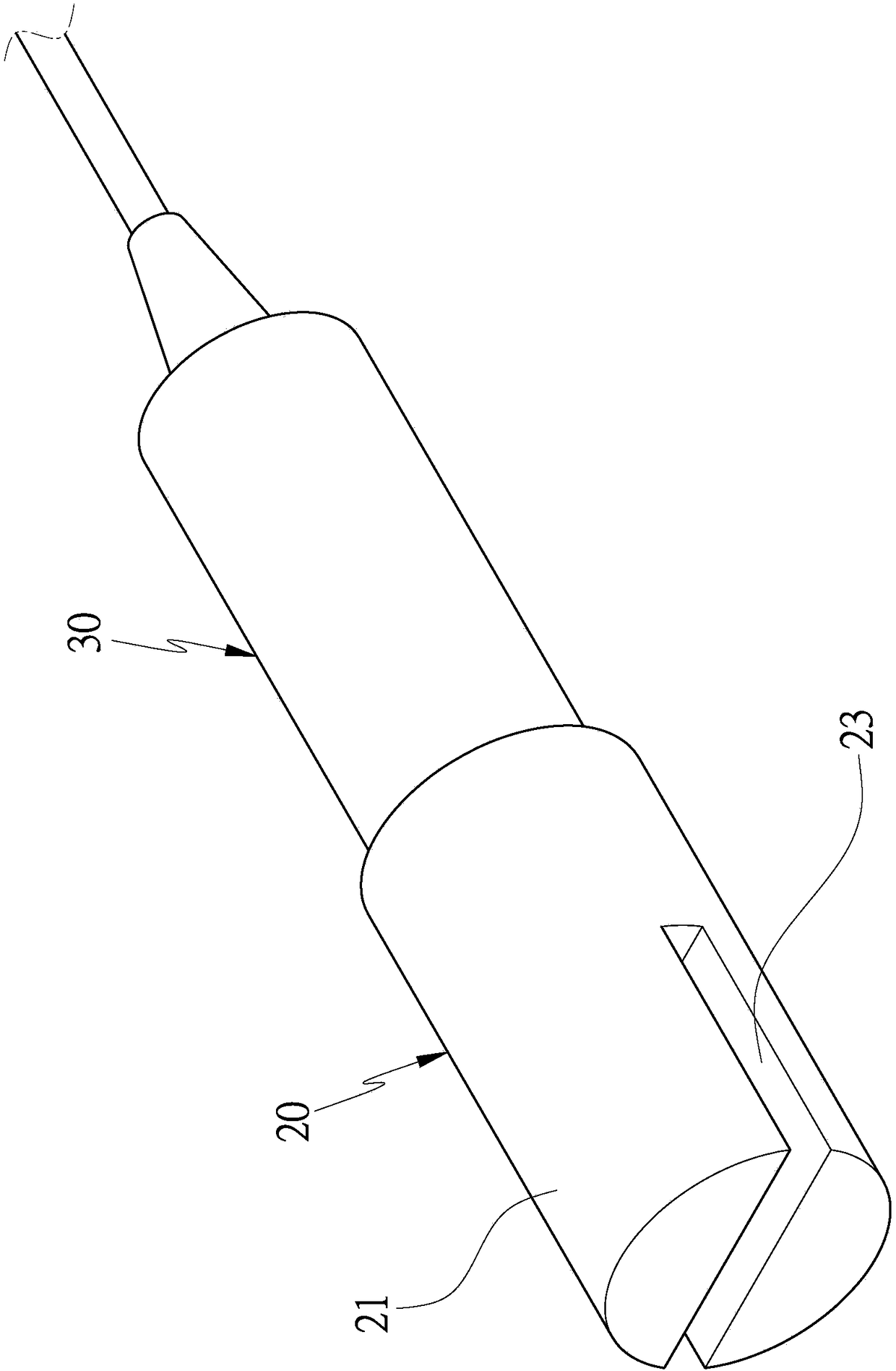

[0020] Such as figure 2 , image 3 , Figure 4 As shown, the protective cover 20 of the proximity sensor provided by the present invention is made of non-magnetic material. In this embodiment, the material of the protective cover 20 is plastic or rubber, and the protective cover 20 is made by injection molding, so that The protective cover 20 is easy to manufacture; the first end of the protective cover 20 is provided with a sleeve portion 22 for being sleeved outside the sensing end 31 of the proximity sensor 30, and the outer surface 21 of the protective cover 20 is located close to The area (non-sensing area) other than the sensing area B of the sensor 30, in this embodiment, the fitting portion 22 is in the shape of a concave hole, and the fitting portion 22 cooperates with the outside of the sensing end 31 of the proximity sensor 30. size, so that it can be fixedly sleeved outside the sensing end 31 of the proximity sensor 30 by means of tight fit, so that the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com