A control method for thyristor reverse recovery period protection by valve control system

A technology of reverse recovery period and valve control system, applied in emergency protection circuit devices, electrical components, power transmission AC network, etc. problems, to achieve the effect of reducing false triggering, ensuring correctness, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

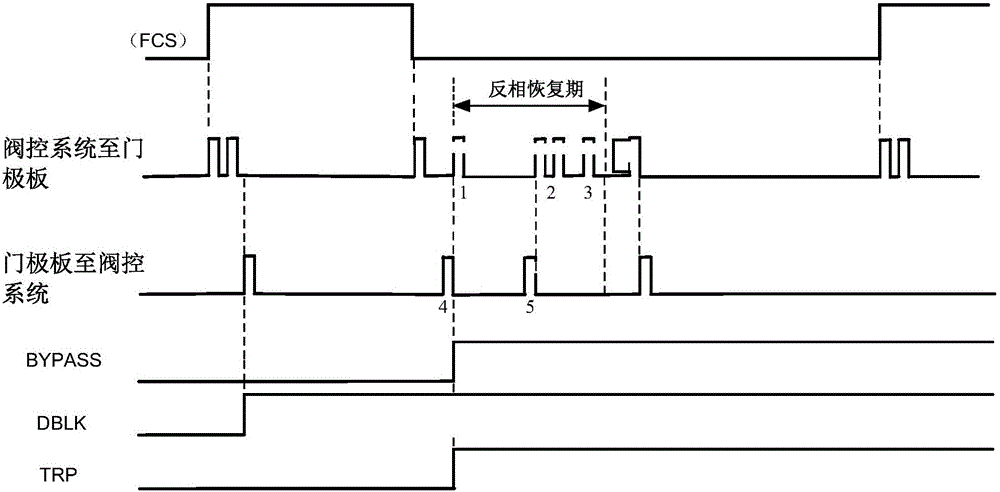

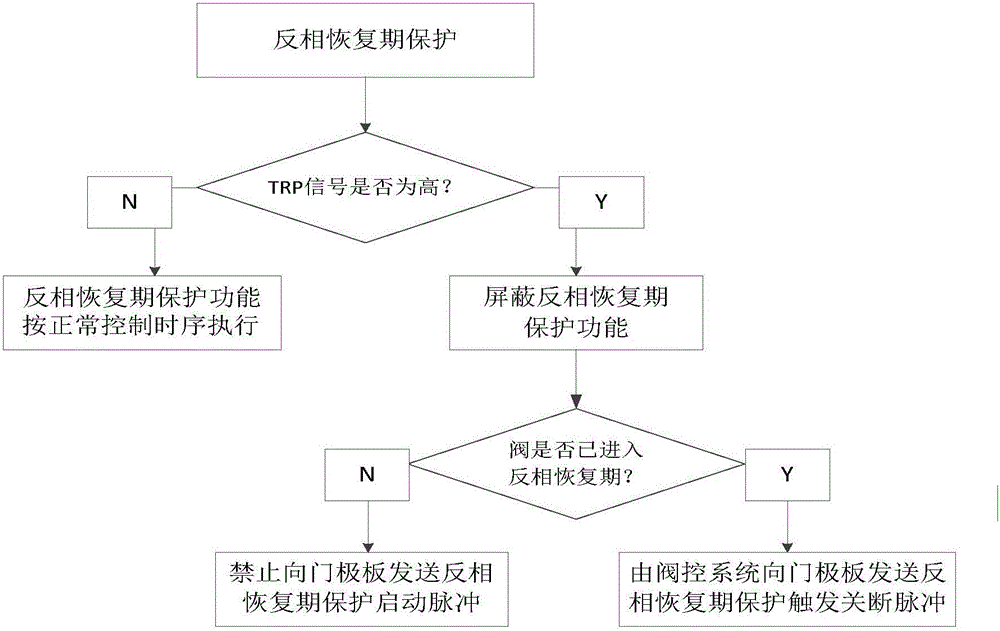

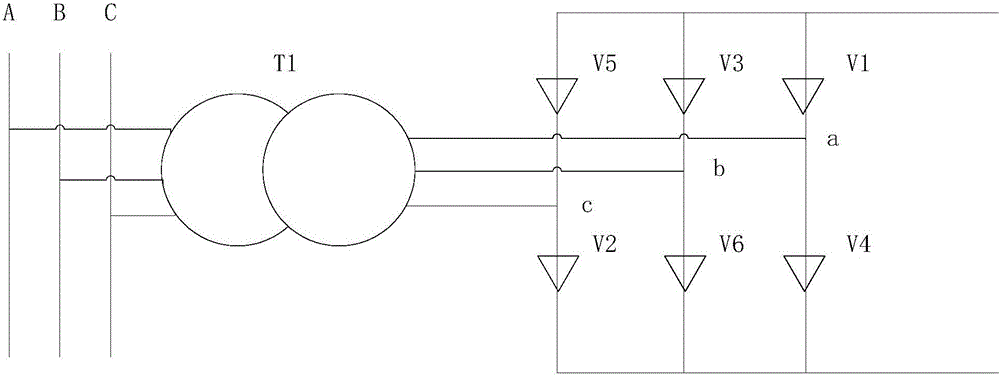

[0021] The valve control system controls the operating state of the gate plate by sending pulse signals to the gate plate, and then realizes the function of controlling the switching on and off of the thyristor of the converter valve. The valve control system mentioned here refers to the converter valve control equipment, the gate plate is the control unit of the thyristor level. The flow diagram and timing diagram of its signal are as follows figure 1 As shown, where FCS represents the converter valve trigger control signal; BYPASS represents the converter valve bypass effective signal; DBLK represents the converter valve unlock signal; TRP represents the reverse recovery period protection control signal.

[0022] The work of the valve control system and the gate plate adopts five-pulse coding, and the control principle of five-pulse codi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com