Method and equipment for measuring wire sag by using tensiometer

A tensiometer and wire technology, applied in tension measurement, measuring devices, instruments, etc., can solve problems such as personnel estimation error, high environmental requirements, deviation between the actual tension of the wire and the design theoretical tension, etc., to improve efficiency and quality, Improved measurement accuracy and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

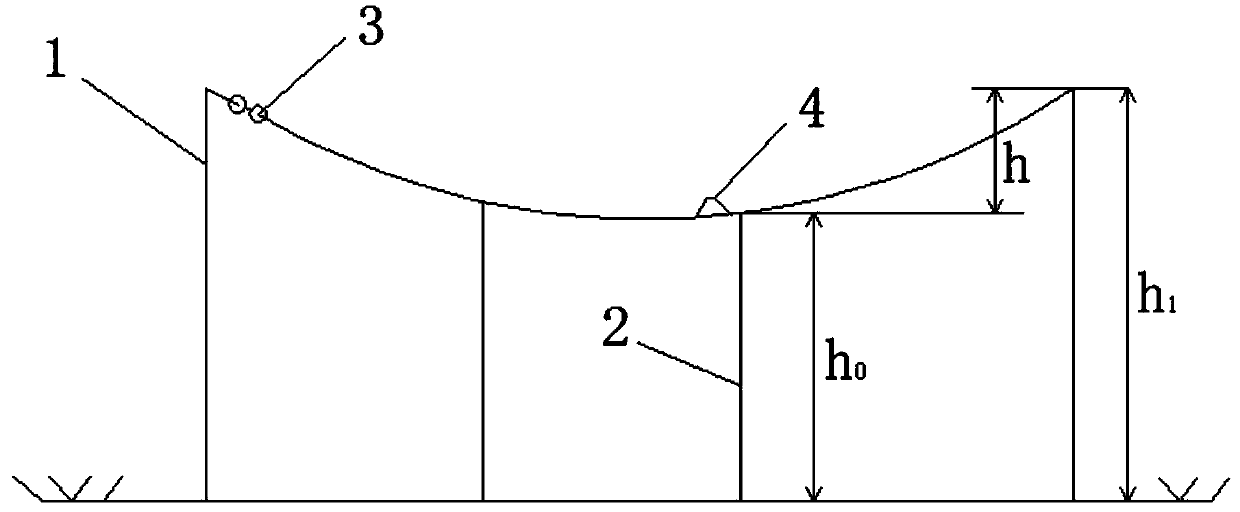

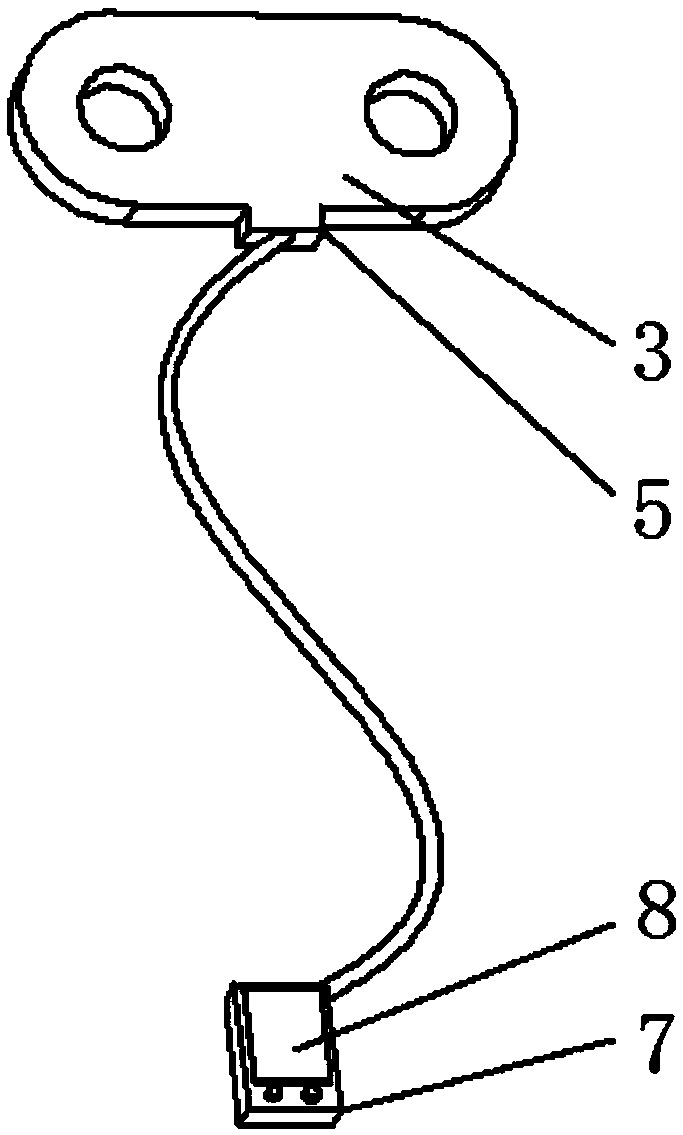

[0062] Measure the sag of the conductor with the span l of the observation gear being 582m, and the specific load g of the conductor is 1.3475kg / m·mm 2 , height h of tension tower 1 hanging point 1 Height h of hanging point with straight tower 2 0 The difference h is 8m.

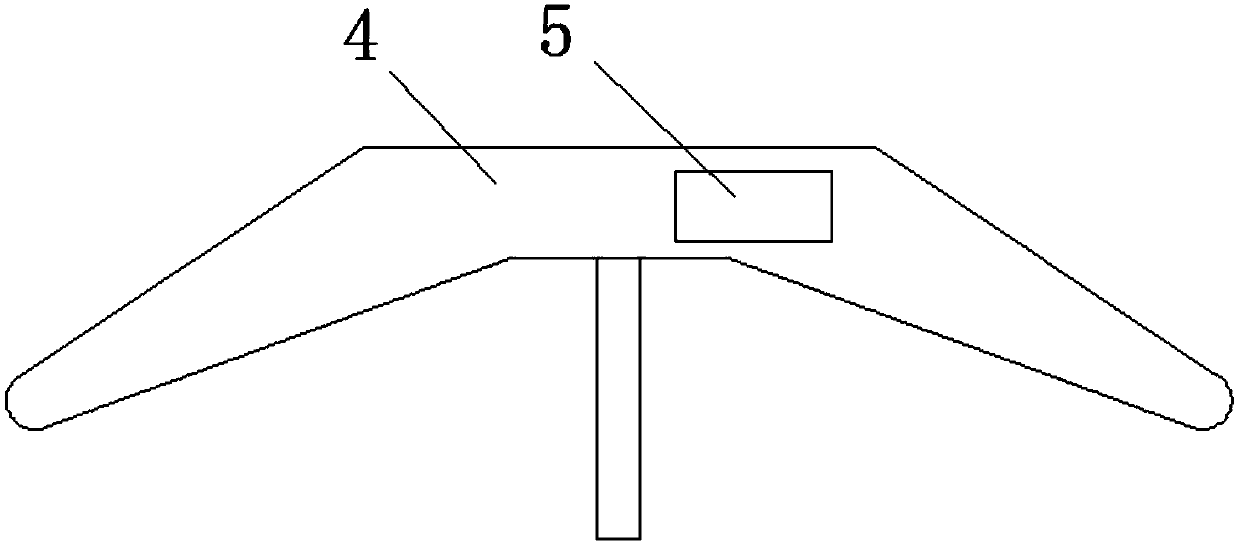

[0063] First utilize the series tensiometer 3 to measure the wire tension value on the tension tower 1 hanging point, and utilize the parallel tensiometer 4 to measure the wire tension value at the straight tower 2 hanging point simultaneously; obtain the wire tension value F on the tension tower 1 hanging point 张 It is: 2678.10kg; the wire tension value F at the hanging point of the straight tower 2 直 For: 2674.06kg.

[0064] Then according to F 张 with F 直 , using the mathematical model formula to calculate the observed file slack For: 21.58m and 21.52m.

[0065] By comparing the above two calculation results, it is verified that the measurement is accurate and usable.

Embodiment 2

[0067] Measure the sag of the wire with the span l of the observation gear being 446m, and the specific load g of the wire is 2.0784kg / m·mm 2 , height h of tension tower 1 hanging point 1 Height h of hanging point with straight tower 2 0 The difference h is 9m.

[0068] First utilize the series tensiometer 3 to measure the wire tension value on the tension tower 1 hanging point, and utilize the parallel tensiometer 4 to measure the wire tension value at the straight tower 2 hanging point simultaneously; obtain the wire tension value F on the tension tower 1 hanging point 张 It is: 3595kg; the wire tension value F at the hanging point of the straight tower 2 直 For: 3520.17kg.

[0069] Then according to F 张 with F 直 , using the mathematical model formula to calculate the observed file slack For: 14.54m and 14.77m.

[0070] By comparing the above two calculation results, it is verified that the measurement is accurate and usable.

[0071] like figure 1 As shown, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com