Efficient self-cleaning energy-storage illuminating light reflection film

A technology of energy storage luminescence and reflective film, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of easy pollution, reflection, poor luminous effect, and small observation angle of reflective film and luminous reflective film, so as to ensure the light Absorption efficiency and luminous effect, enhancement of luminous intensity, and effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

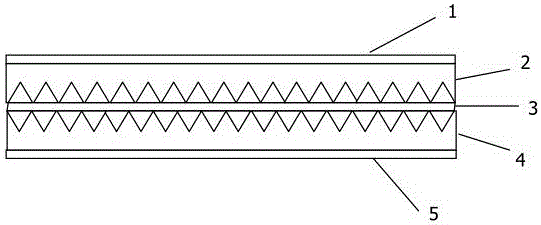

[0019] Such as figure 1 As shown, a high-efficiency self-cleaning energy-storage luminous reflective film includes a self-cleaning coating 1, a reflective film layer 2, an air layer 3, an energy-storage luminescent reflective film layer 4 and an adhesive layer 5 from top to bottom.

[0020] Self-cleaning coating 1 made of TiO 2 Sol and SiO 2 Sol preparation, TiO 2 Sol and SiO 2 The sol ratio is 1:2. The self-cleaning coating is plated on the surface of the reflective film layer 2, has super-hydrophilic properties, and can play a self-cleaning effect under the washing of rainwater.

[0021] The reflective film and the luminous reflective film in the reflective film layer 2 and the energy-storing luminous reflective film layer 4 are prepared from acrylic resin and rare earth excited metal aluminate luminescent material, and its initial luminous brightness is 4000mcd / m 2 , the brightness is 4 mcd / m after continuous light emission for 12 hours 2 , the luminescent color is ye...

Embodiment 2

[0026] Such as figure 1 As shown, a high-efficiency self-cleaning energy-storage luminous reflective film includes a self-cleaning coating 1, a reflective film layer 2, an air layer 3, an energy-storage luminescent reflective film layer 4 and an adhesive layer 5 from top to bottom.

[0027] Self-cleaning coating 1 made of TiO 2 Sol and SiO 2 Sol preparation, TiO 2 Sol and SiO 2 The sol ratio is 1:3. The self-cleaning coating is plated on the surface of the reflective film layer 2, has super-hydrophilic properties, and can play a self-cleaning effect under the washing of rainwater.

[0028] The reflective film and the luminous reflective film in the reflective film layer 2 and the energy-storing luminous reflective film layer 4 are all made of polypropylene resin, polyester resin and silicate long-lasting luminescent material, and its initial luminous brightness is 4500mcd / m 2 , the brightness is 4.5mcd / m after 12 hours of continuous light emission 2 , the luminescent col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com