Battery module structure

A technology for battery modules and battery packs, which is applied to battery pack components, secondary batteries, structural parts, etc., can solve the problems of burnt components, assembly errors, low consistency, etc., and achieves high reliability and convenient maintenance and repair. , space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

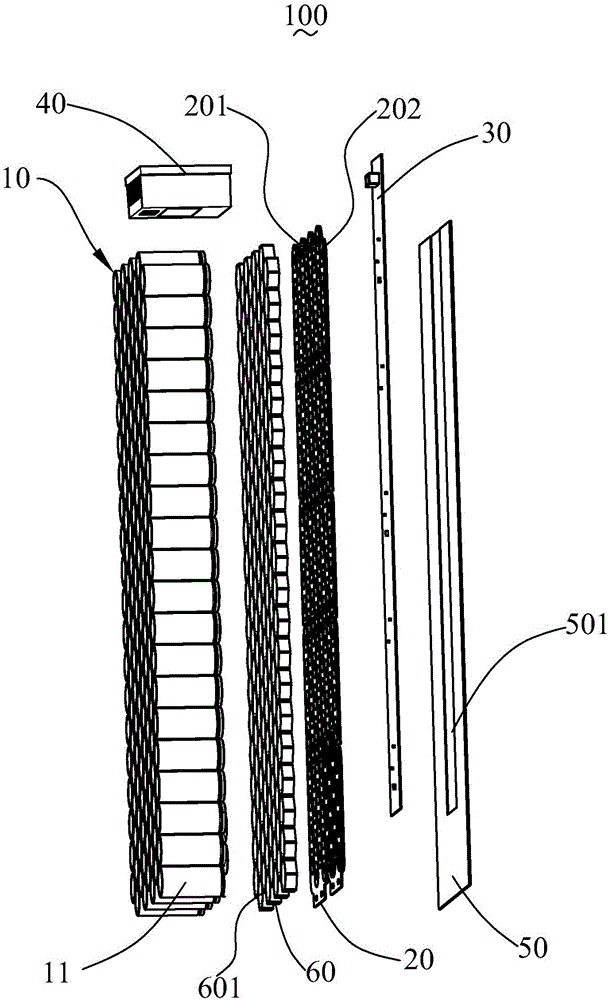

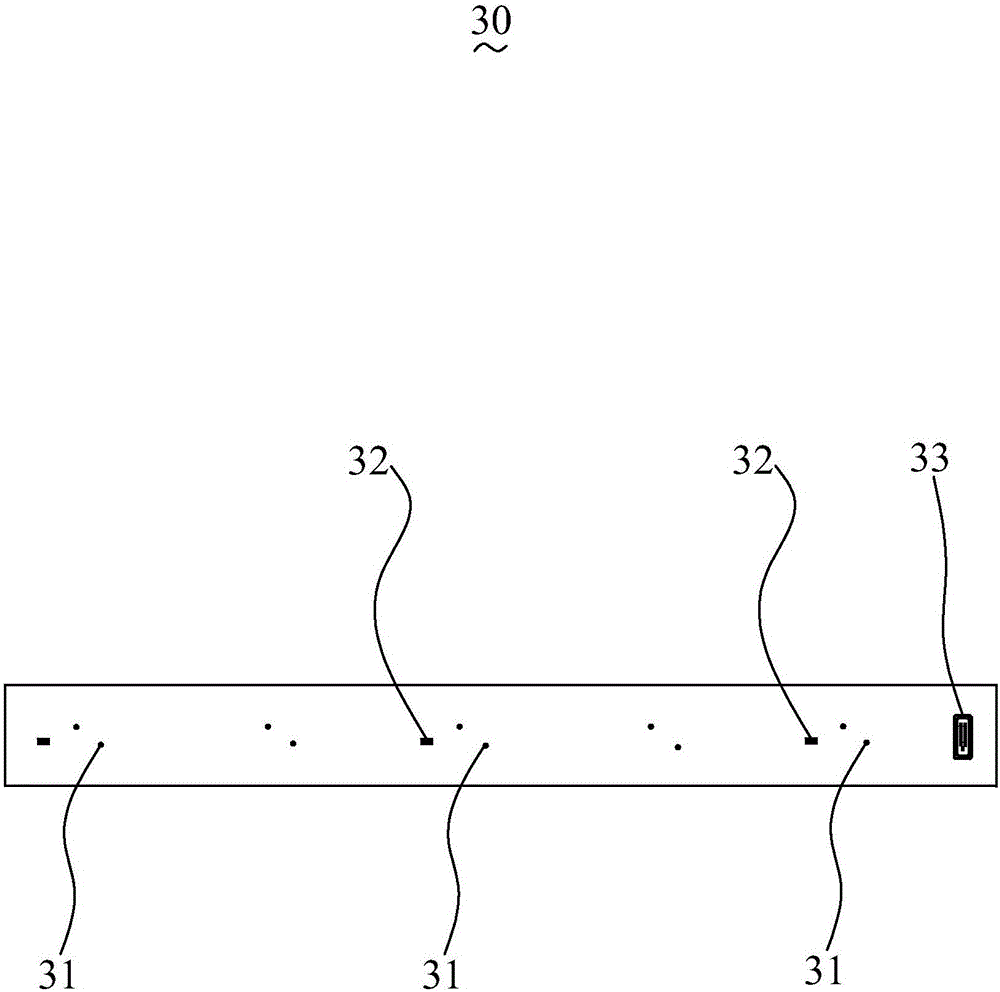

[0027] like figure 1 As shown, the present invention provides a battery module structure 100 including a plurality of battery packs 10 , a bus board 20 and a collection board 30 .

[0028] Each battery pack 10 is composed of a plurality of single cells 11 arranged side by side, all the single cells 11 in each battery pack 10 are connected in parallel, and the single cells 11 are cylindrical.

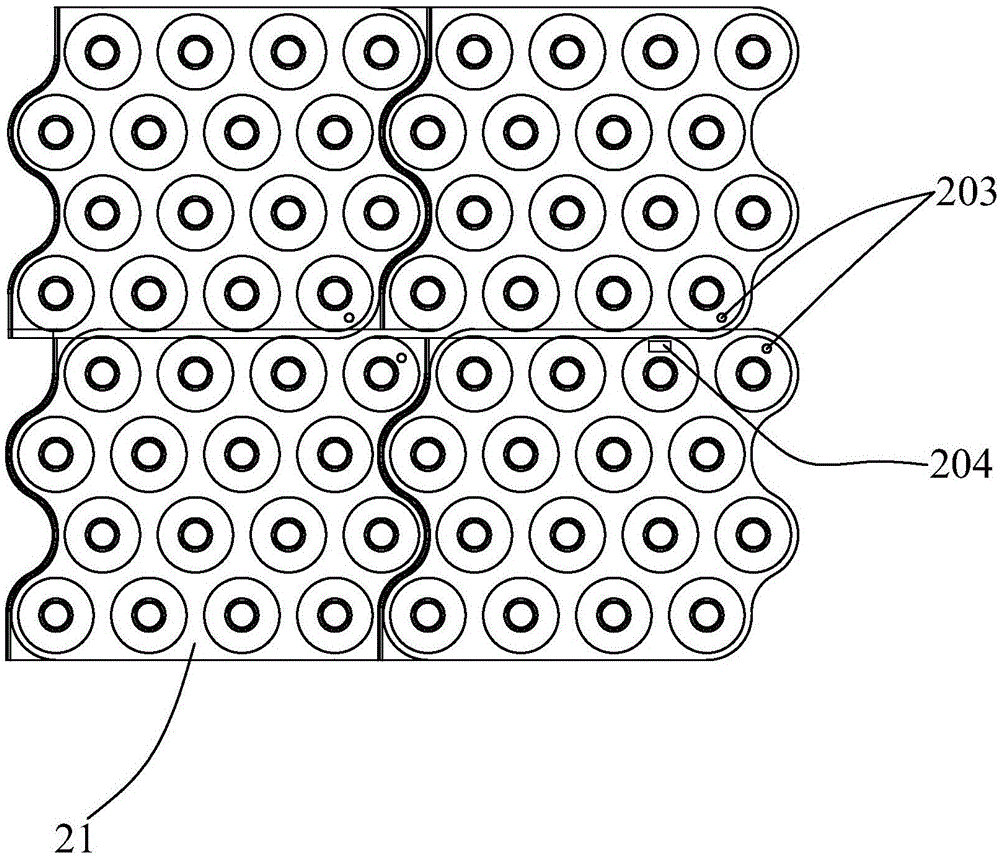

[0029] Please also refer to figure 1 and figure 2 , the manifold 20 includes an upper surface 201 and a lower surface 202 opposite to the upper surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com