Motor vehicle battery

A technology for motor vehicles and batteries, applied in secondary batteries, battery pack components, battery covers/end covers, etc., to achieve the effect of effective heat transfer and reduction of temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

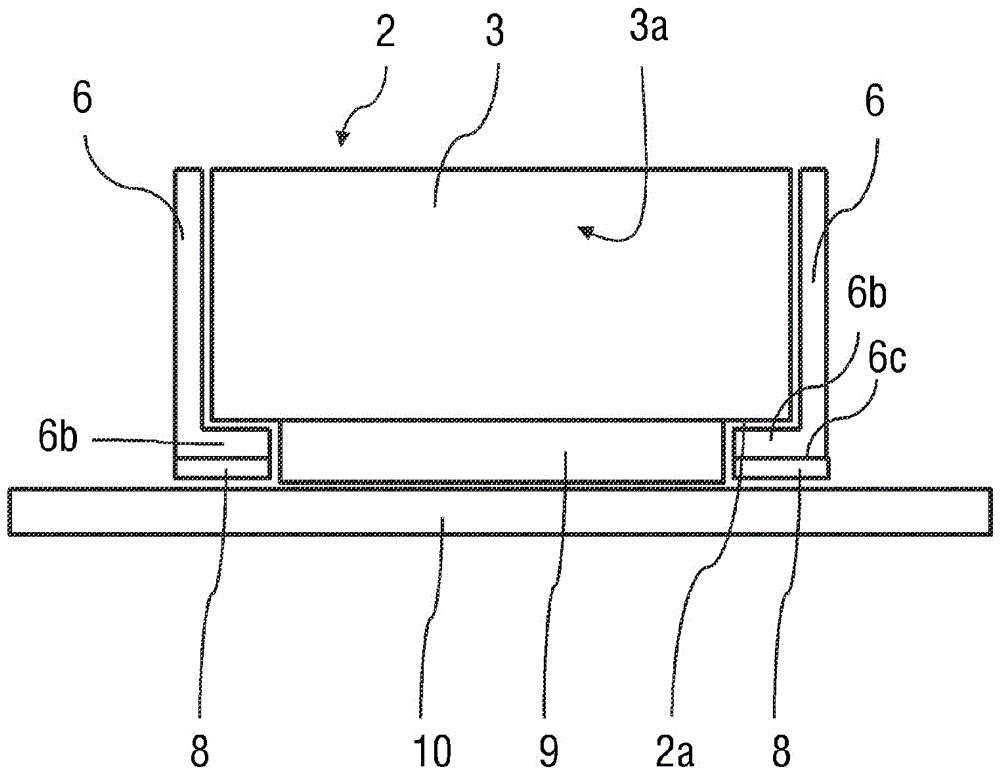

[0031] Identical or functionally equivalent elements are provided with the same reference symbols in all figures and are not described separately.

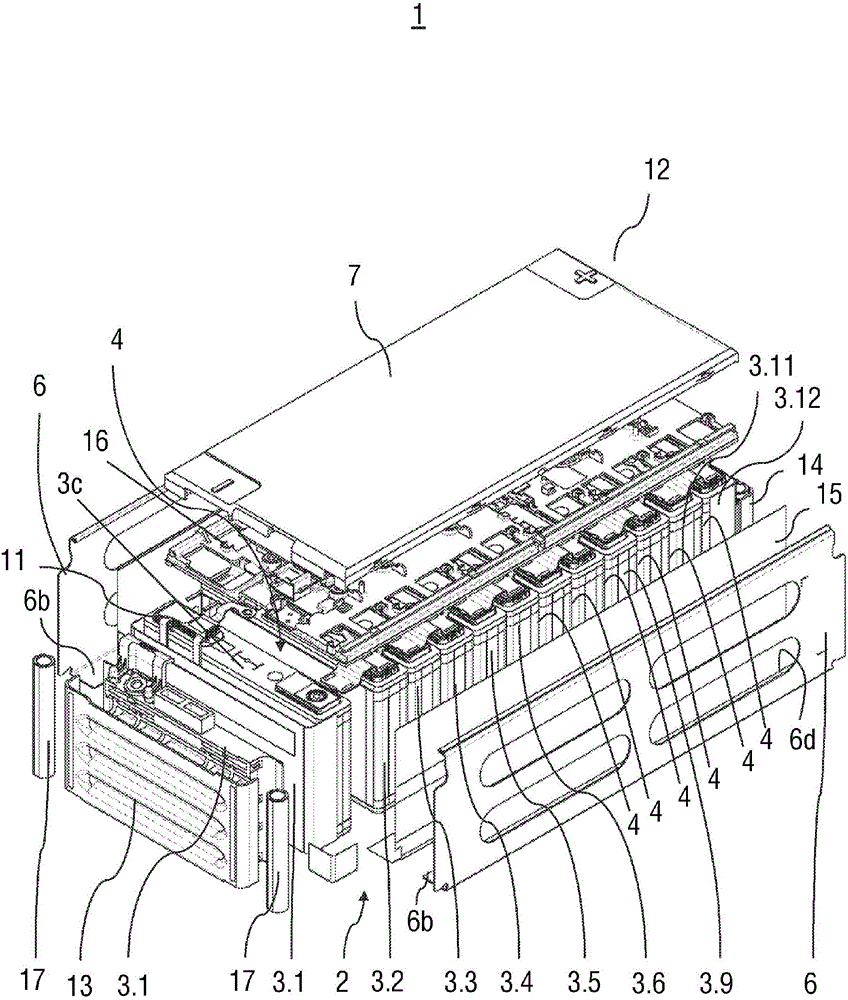

[0032] The basic structure of the motor vehicle battery according to an embodiment of the invention corresponds to figure 1 The structure shown in , so only the special features of the development of the motor vehicle battery are explained below.

[0033] and figure 1 In contrast to the construction shown in , the recess 6d is not inserted into the two side parts 6 . Rather, the side part 6 has a continuous covering surface. In addition, in figure 1 The paper layer 15 shown in is eliminated.

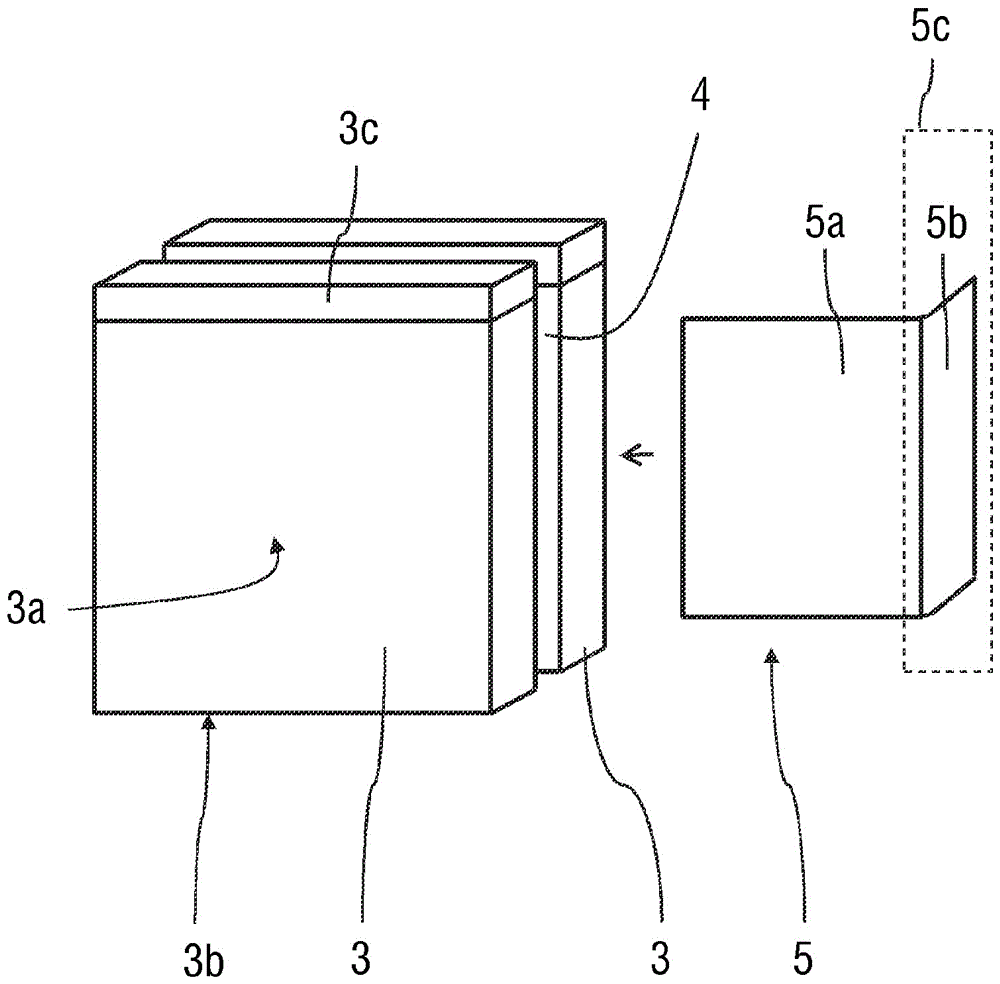

[0034] Another special feature is that, with figure 1 The difference is that the heat-conducting film 5 is now inserted into the intermediate region 4 formed between two adjacent battery cells 3 in each case.

[0035] this is in figure 2 is depicted in a very schematic diagram. figure 2 Two of the twelve battery cells 3 of the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com