Digital management system for non-ferrous metal metallurgy

A management system, non-ferrous metal technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of large manual calculation workload, cumbersome calculation, and high errors, and achieve the effect of convenient query and accurate batching data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

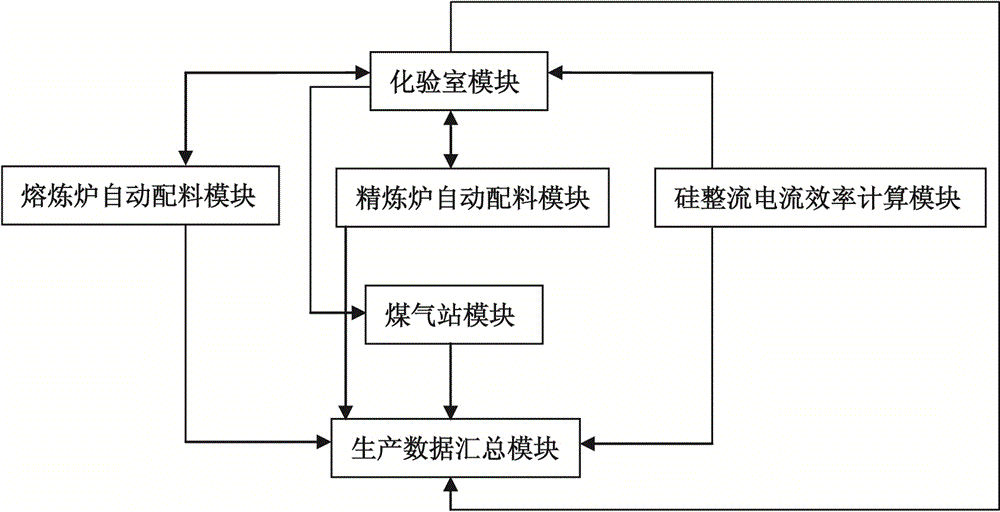

[0032] Such as figure 1 As shown, the system includes a server for storing data and 6 workstations, and also includes the automatic batching module of the smelting furnace, the automatic batching module of the refining furnace, the current efficiency calculation module of silicon rectifier equipment, and the laboratory Room module, gas station operation record management module and production data summary module; each workstation has a computer, and each computer is connected to a display terminal and a printer. Silicon rectification devices are also included. The system can increase the number of workstations according to actual production needs.

[0033] The laboratory module includes the entered laboratory data of main materials, auxiliary materials, coal, semi-finished products and finished products, as well as the personal information of laborato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com