Stirring mechanism capable of simultaneously blending multiple parts of face mask liquid

A technology of stirring mechanism and facial mask liquid, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve problems such as poor user experience, inability to meet multiple film-making requirements of fruit film machines, troublesome operation, etc., to achieve Improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

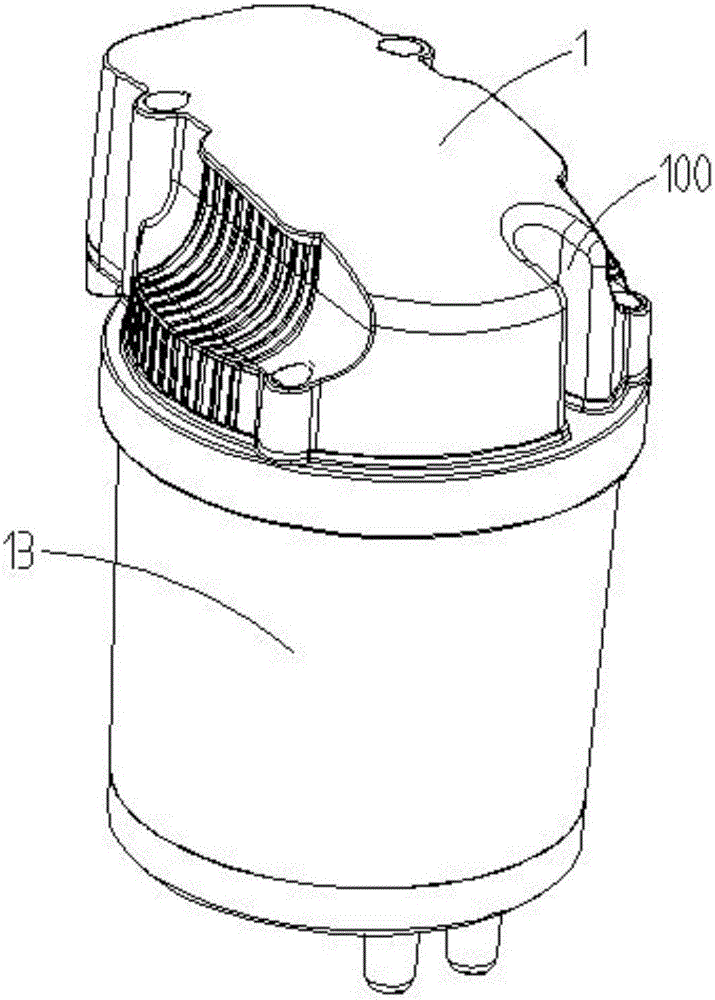

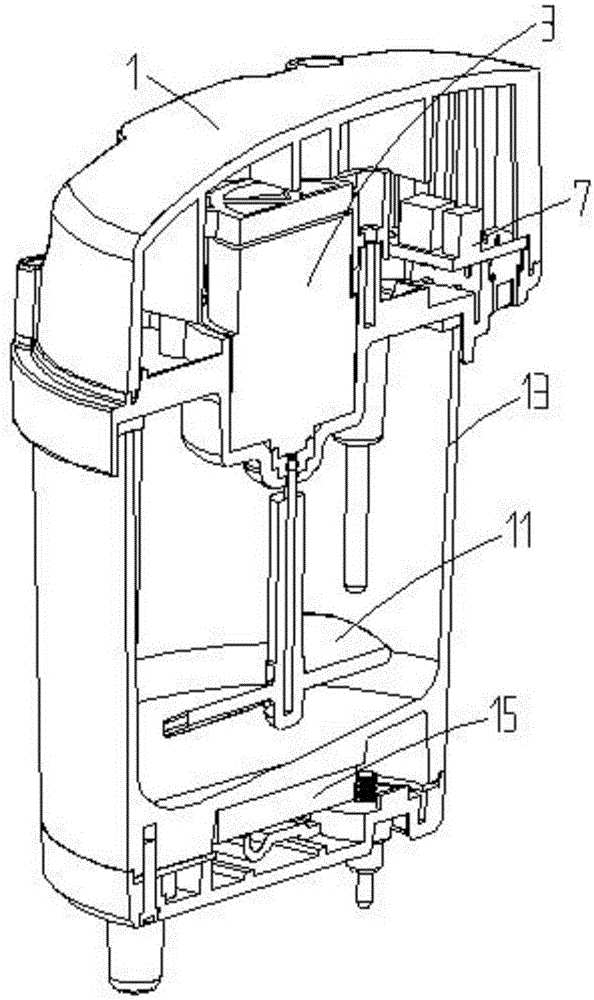

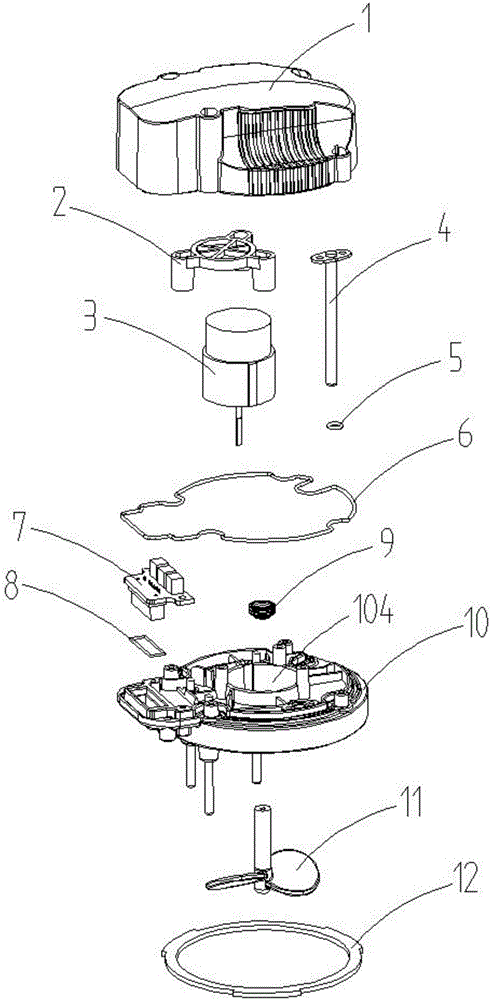

[0027] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, the present invention is a kind of agitating mechanism that can deploy multiple portions of mask liquid at the same time, comprising:

[0028] The cup cover assembly, the cup cover assembly includes a stirring cup upper cover 1 and a stirring cup middle cover 10 assembled together, and a PCB board 7, a stirring motor 3, a thermistor 4 and A plurality of liquid level probes of different lengths, the PDB board 7 is electrically connected to the stirring motor 3, the thermistor 4 and the plurality of liquid level probes respectively, and the rotating shaft of the stirring motor 3 goes toward After passing through the middle cover 10 of the stirring cup, it is connected with a stirring blade 11, wherein the thermistor 4 is inserted on the middle cover 10 of the stirring cup from top to bottom and fixed by screws; and

[0029] Cup body assembly, the cup body assembly includes a cup body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com