Damping wheel hub of air inflation-free tire

A technology of air-free tires and shock-absorbing wheels, which is applied in the field of auto parts, can solve problems such as poor shock resistance, poor ability to adapt to road surfaces, troublesome use, etc., and achieve the effect of improving adhesion and driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

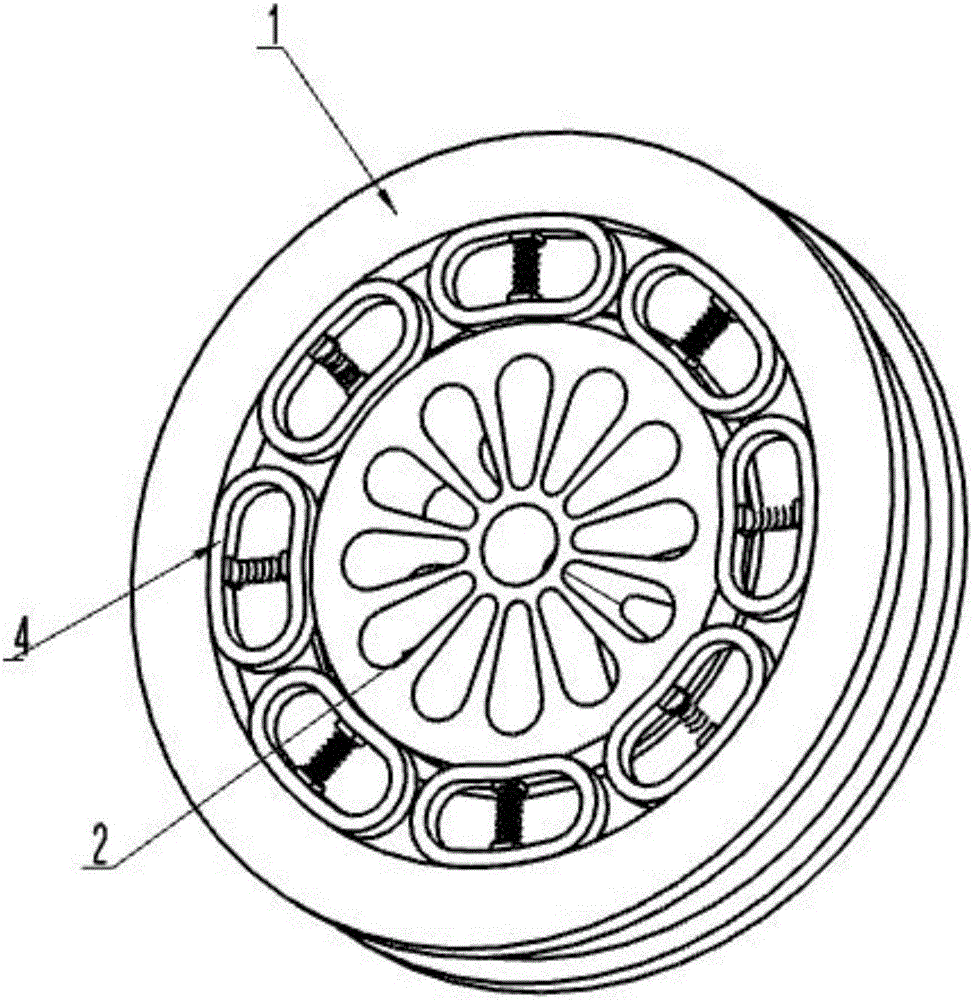

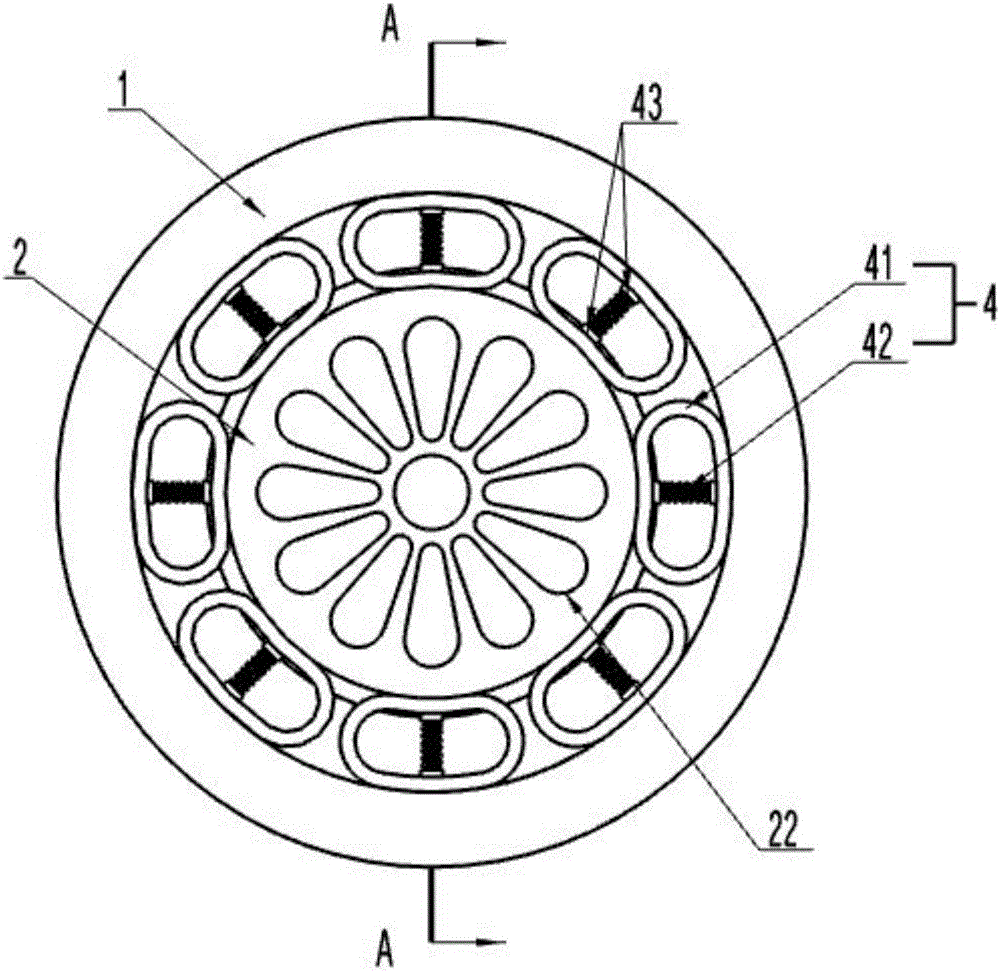

[0025] like figure 1 As shown, the present invention provides a shock-absorbing hub for a non-pneumatic tire, including a hub body, the hub body includes an outer ring 1 and an inner ring 2 arranged concentrically, a buffer portion is arranged between the outer ring 1 and the inner ring 2, and the outer ring 1 and the inner ring 2 are provided with a buffer. There is a certain gap between the ring 1 and the inner ring 2. When the outer ring 1 receives a radial impact, it can be buffered by the buffer part, so that the outer ring 1 has a certain space for movement in its radial direction, so it can play a role in buffering and The role of shock absorption.

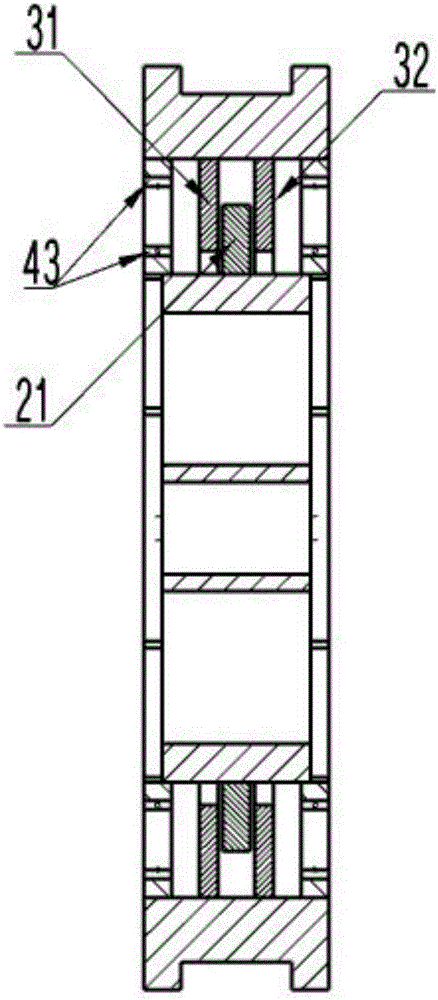

[0026] Preferably, the distance between the buffer part and the left and right side walls of the outer ring 1 is the same, so that the buffer part can achieve better shock absorption effect; Belt 32 and the clamping ring 21 positioned on the outer circumferential surface of inner ring 2, the width of the first buffer zone ...

Embodiment 2

[0037] On the basis of Embodiment 1, the outer ring 1, the inner ring 2 and the buffer part 3 are all made of carbon fiber. The hub made of carbon fiber has multiple advantages such as lighter weight, high strength, high modulus, low density, small linear expansion coefficient, etc., and has two characteristics of strong tensile strength of carbon material and soft processability of fiber.

[0038] In summary, the present invention provides a shock-absorbing wheel hub for a non-inflatable tire. By setting a buffer between the outer ring 1 and the inner ring 2, the defect of insufficient return force of the non-inflatable solid tire can be compensated; when the outer ring 1 After being subjected to radial impact, there will be a certain activity space, so it can play the role of buffering and shock absorption, and improve the driving stability during driving; an elastic member 4 is set between the outer ring 1 and the inner ring 2, and through its own The elastic deformation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com